In the age of GPS, DGPS, WAAS GPS and handheld GPS systems, how important is the magnetic steering compass? Just ask anyone who has been disoriented at night, turned around in the fog, or been on the receiving end of an electrical storm. Magnetic compasses are installed at almost every helm for a reason—to provide a reliable heading by which to navigate, independent of all the other on-board systems. When referenced against today’s technologies, the heading from a magnetic steering compass is a silent backup that carries a significant amount of clout.

Background

Zheng He from China is recorded as the first person to have used a magnetic compass as a maritime navigational aid. History reports that Zheng He made seven ocean voyages between 1405 and 1433.

During the 1800s, the British designed and built the first commercially available magnetic steering compass, specifically for ocean navigation, based on a dry card design. Throughout the late 1800s, the British Navy outfitted its sailing vessels with large, flat-top, dry-card magnetic compasses, and managed for the most part to navigate with precision. One of the drawbacks of the British-designed compasses was that they had no dampening (also known as “damping”) fluid. Thus the compass card and needle would wildly oscillate as the ship yawed in a moderate sea because of the lack of a dampening force being applied to the compass’s card.

The compass cards on these early magnetic compasses were marked out in points of the wind and not in degrees. There were 32 wind points, derived from the four cardinal wind points—North, South, East, and West. It wasn’t until the early 1900s that the numerical (000 to 359 degree) system was added to the compass card. Throughout the 1800s, the north point on most compass cards was very ornate and often represented by a fleur de lys. In actuality, the ornate north point originated as an overly decorated letter “T,” representing the Latin word Tramontana, which means north wind.

In 1861, on the other side of the Atlantic, an innovative instrument maker named Edward Samuel Ritchie, working out of a shop in Boston, began improving and manufacturing a liquid-filled maritime compass based on an English design patented in 1813. By 1862, Ritchie had made significant improvements to his first generation liquid-filled compass, which caught the attention of the U.S. Navy. Ritchie improved his next generation maritime compasses by “floating” the card in the dampening fluid. This he accomplished by enclosing the compass’s pivoting needle in a brass box of sufficient bulk to float and bear a portion of the weight of the card.

The US Navy thoroughly tested Ritchie’s design and found that the new compasses possessed adequate sensitivity and superior steadiness, without being in any way deficient in directive power when compared to an Admiralty dry-card compass. The Navy’s endorsement of Ritchie’s innovation helped Edward Ritchie secure a U.S. patent. By the end of that year, E.S. Ritchie & Co. was formed and became the preferred compass supplier to the U.S. Navy. It would take the British Admiralty another 40 years to retire its dry-card compass standard in favor of the liquid-filled compass.

Electronic vs. Magnetic

Now, some 143 years later, we are still equipping our most sophisticated commercial vessels with flat-top style compasses, based in part on E.S. Ritchie’s early innovations. Recently PS was on the bridge of M/V Chenega, the state of Alaska’s newest addition to its marine super highway. The Chenega is a 235-foot ferry capable of carrying 250 passengers and 35 autos at a service speed of 35 knots, in a sea of 15 feet. This vessel is fitted with every conceivable navigational aid on the market (wave-height sensors, hull-stress sensors, and night-vision imaging, to name a few). Prominently installed into the overhead of the bridge is a flat-top magnetic compass with a sensing coil that is wired back to a navigational compass-monitoring computer. This computer will monitor and compare the ship’s digital gyro compass heading against the conventional magnetic compass, sounding an alarm if the headings differ by a preset amount. The fault and effect module of the compass-monitoring CPU is based around the magnetic compass alerting the system to a possible gyro compass error. It’s evident that today’s super technology has still not replaced the magnetic steering compass.

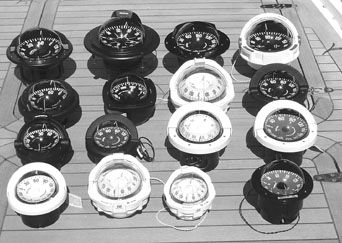

Ship’s steering compasses can be broken down into two basic groups, electronic and magnetic. In the electronic group (compasses that require electrical current to operate), you have the fluxgate compass, the standard gyro compass, the digital gyro compass and the ring laser gyro compass. In the magnetic group, there is the basic flat-top magnetic compass and the spherical or domed magnetic compass. Our test comparison focuses strictly on spherical magnetic steering compasses, the most common type found on recreational vessels from 16 to 60 feet.

Performance Test

The test field consisted of compasses with card sizes between 3.25″ and 6.0″ apparent. We contacted the manufacturers that had submitted products for our test, and asked each about their particular products’ performance standards. We learned that there is no industry-standard performance test that is applicable to recreational magnetic steering compasses. Every manufacturer builds to its own self-imposed level of performance. However, it seems reasonable to expect that since magnetism is a phenomenon of nature, each similarly sized compass will respond similarly to the earth’s magnetic field. Our test results point to quite a different conclusion.

In the absence of a “recreational” standard, we researched what would be required for a magnetic compass to be approved for use on a commercial vessel that is subject to IMO (International Maritime Organization) regulations. Our search yielded ISO document number (10316) “Shipbuilding-Class B Magnetic Compasses/Tests and Certification.” It was also suggested to us by a well-known Rhode Island compass adjuster that we obtain a copy of the US Navy document 18C1D dated 1945, titled “Magnetic Compass Specification, US Navy Bureau of standards, Mark 1 7-1/2″ Card.” After reading these documents, we were easily able to extract the essence of what performance attributes are important for a magnetic compass to possess.

Friction Error — First, we placed a test compass on a smooth, level, non-magnetic countertop and allowed the compass’s card to come to a complete rest. We referred to this as the start position. Keeping our eyes sharply on the exact heading that the compass’s lubber line was oriented to, we slowly and gently rotated the compass clockwise a fraction of a turn and then counterclockwise a fraction of a turn. We were looking to verify that the compass’s card remained absolutely stationary during this slewing, indicating that the compass’s jewel movement is free of defects. Any movement of the card during this test would yield a failing grade.

Sensitivity — With the compass back at the start position, we lined up the compass’s lubber line precisely with a card gradation mark. We then introduced a mildly magnetic jeweler’s screwdriver into the compass’s field from the starboard side of the lubber line, just enough to deflect the compass card clockwise by one degree. We then removed the screwdriver from the compass’s field and observed if the card returned back to its exact original position relative to the lubber line. We repeated the procedure, but this time deflected the card one degree counter-clockwise. If the compass card didn’t freely come back to rest at the exact lubber line reference point, or if the card appeared to “stick” as the screwdriver entered the compass’s field, then the sensitivity of the card’s jewel movement was unacceptable and a failing grade was recorded. Stickiness could be caused by either an imperfect fit between the pivot and the jewel bearing, or dirt/impurities in the jewel cup. Either way, it is nearly impossible to accurately adjust a sticky compass, so those should be avoided.

Dampening — Per the US Navy Bureau of Standards 1945 document, we deflected and held the test compass’s card at +30 degrees from rest (using a medium strength flinder bar that we salvaged out of an old flat-top compass). We then removed the flinder bar, which released the compass’s card and recorded the number of degrees of over-swing past the zero mark. The procedure was repeated again with a card deflection of –30 degrees from rest. The Navy’s standard was created to test a 7-1/2″ flat-top compass, and the maximum allowable over-swing was not to exceed 11 degrees. Thus the Navy’s threshold is not as applicable to our test field of smaller spherical compasses as the test procedure itself. Therefore, we recorded the amount of over-swing, creating our own group average.

Period — We timed each compass’s period in accordance with the Navy Standard as follows: “After release of the card from the +/- 30 degrees, the time required for 25 degrees (from 25 degrees to 0 degrees) swing shall be not less than 5.5 seconds and not more than 6.8 seconds.” As with the dampening values, we created our own group average value. ISO 10316 quantifies this particular test in a different manner: “After an initial deflection of 90 degrees, the card shall return to its original position to within 2 degrees in no more than (65 divided by the square root of H) expressed in seconds,” where “H” is understood as the horizontal component of magnetic flux density, expressed in Microtesla at the place of examination. It takes a good amount of searching the U.S. Geological Survey records to determine that the horizontal component of magnetic flux density in New England (2005) is 19.503 Microteslas. As we are more comfortable with a stopwatch than with a calculator, we deferred the compass period test to the U.S. Navy Standard.

Readability (day and night) — Per ISO 10316: “In steering compasses, the line thickness and the heights of figures and letters shall allow a person with normal vision to read the card, in both daylight and artificial light, at a distance of one meter.” Our test adhered to the one-meter distance, and we scored the daytime legibility of each compass card (using our tester’s late-40-something, 20/20 vision) and the nighttime legibility with each unit’s DC illumination turned on.

Brunton

Brunton compasses are manufactured in Sweden by Silva and marketed in North America through ComNav Marine Ltd., which is located in British Columbia, Canada. The parent company has phased out the marketing of the similar Nexus and Silva line of compasses in North America in favor of the Brunton nameplate. Although its 150-F compass tested well, it was nearly impossible to find one locally in a store to evaluate, nor did a Google search provide us with any assistance in price shopping. The five-page photocopied manual that came with the compass was void of any warranty information and not a single support telephone number was anywhere to be found on the pamphlet. We immediately turned to the ComNav website to view its support of the Brunton 150-F, and the model was briefly listed in the compass features matrix section on this site. ComNav provides a 10-year warranty on its entire Nexus recreational boating compasses range, including the Model 150-F.

C. Plath

A division of the Litton Marine Systems (C. Plath, Decca, Sperry), Plath manufacturers its line of precision compasses in Hamburg, Germany. The C.Plath Merkur is the only compass in our test that includes a glass (not plastic) dome, and the entire body and mounting flange is aluminum alloy. All other compasses in our group have either all-plastic bodies and mounting flanges, or a combination of plastic bodies and alloy flanges. In working, holding, and testing this compass, it becomes apparent that this compass is a precision instrument, designed and built by craftsmen, not “assemblers.” Plath offers a lifetime warranty on its glass domes, and three years on all other components. It should be noted that the mounting flange on this compass is not as wide as on others. Therefore the hole cut-out that is called for in a flush-mount installation needs to be sized exactly, otherwise your flange mounting screws will fall inside the cut-out and have nothing to fasten to.

Danforth

Danforth compasses are produced by an ITT industries company that is heavily marketing its “Global Balance” card system. Danforth says that this new card system guarantees a perfectly level card, anywhere in the world. ITT is retiring the Aquameter trade name and rolling the Saturn, Cruiser, and Skipper products into the Danforth group. Danforth shares the U.S. market with Ritchie in the number of different models offered, but its warranty is only three years vs. Ritchie’s five years.

An area of concern that we have with Danforth is in the method that the company uses to protect the products during shipment. Danforth just wraps its compasses with two courses of bubble wrap and dunks them into the point-of-sale box, without any cardboard restraints. Although UPS delivered our Danforth products in good shape, we question the logic in allowing a precision instrument to flop around inside the box. Kudos to the bubble wrap, but it just doesn’t seem normal to shake a packing box and feel your liquid compass rolling around. Danforth usually includes a compass cover on most models. The 3-3/4″ Corsair IV models come with the new telescoping cover, and are starting to look very modern, like a Plastimo. But unlike a Plastimo, when the Danforth compass is ordered in black, the telescoping cover is also black.

Navimo/Plastimo

Navimo USA, formerly Plastimo USA, is the North American importer of Plastimo compasses, which are manufactured in Lorient, France. Plastimo (established in 1963) is considered a European expert in the use of plastic materials for the marine industry. This is why all of Plastimo’s compasses are made almost entirely of plastic materials. Unique to the Plastimo line is that these compasses are hermetically sealed (i.e. not repairable). The “telescoping” sunshields on the 105 and 135 models are built right into the compass and therefore cannot be lost or blown overboard. Opinions on Plastimo products vary. Many boatbuilders love them because they have a contemporary look, which tends to keep a helm looking fresh. The traditional compass service centers dislike them because they are factory sealed and are basically considered disposable or exchangeable.

So where does that leave us? Plastimo provided PS with multiple color brochures. Some of the excerpts from the brochures read as follows: “Every compass card is balanced manually to ensure it’s perfect horizontality…This is an extremely delicate operation, requiring patient and scrupulous craftsmanship.” And “precious components are produced by Swiss clock-makers, famous worldwide for their legendary precision.” Unfortunately, the lubber line was so far skewed from vertical on the Olympic 135 that we took the compass to an independent compass shop for a second opinion. It was confirmed (at 41 degrees latitude) that the gimbal pan and card on our new Olympic 135 were out of balance. Also observed was debris (some metallic flecks and a small 1/4″ white fiber) on the card of the Olympic 100.

Navimo president Steve Paley said our experience with the 135 and 100 was not indicative of the quality of Plastimo compasses. “This was a one-time instance,” he said. “No one is 100 percent spot-on with their products. We’d be happy to provide you with more compasses.”

Ritchie

E.S. Ritchie and Sons, Inc., an icon of the American marine manufacturing industry, has been building its compasses in Massachusetts for almost a century and a half. It was Ritchie that built the Navy’s Mark 1 Bureau of Standards compass, which was subcontracted out to Lionel Corp. of New York (the well-known toy train maker) during WWII to meet wartime production needs.

Ritchie’s product line closely matches that of Danforth’s. It’s natural to lay the 3-3/4″ Ritchie SuperSport next to the Danforth 3-3/4″ Corsair IV and the Ritchie 5″ Globemaster next to Danforth’s 5″ Constellation. In the 3-3/4″ series, we prefer the visibility of Ritchie’s Blue card over Danforth’s black one, and found the silk-screened manufacturer’s logo that Danforth places on top of its sunshield, too much. One logo per compass, please. In the 5″ match-up, we found Ritchie’s glossy black mounting bezel distracting and the shade color of yellow that is used on the lubber line to be indistinguishable from white in low light. Danforth’s Constellation comes with a flat black mounting bezel and a prominent yellow lubber line. At night, Ritchie’s Globemaster has a better lighting pattern. None of the Ritchie compasses that we tested come standard with a cover. But, the Ritchie website, which is well laid out and full of content, receives top honors.

Conclusions

In the large-compass field (4-3/4″ to 6″ apparent), the Brunton and Plath stacked up well against the Plastimo 135 Offshore and the Ritchie Globemaster. Danforth’s heavy dampening and long period on its 5″ Constellation cost the product a spot among the top four.

The card movement on the Brunton 150 was the smoothest of the 16 compasses tested. When we approached the Brunton with our bar magnet, its card repelled against the magnet in a predictable manner, without jumping or dipping. Brunton also boxes the North indicator on its card with a large red arrow, making it possible to identify North at distances greater than 10 feet. But, because the price ($795) seems such a hefty investment and because local support and customer service remain unresolved issues with Brunton’s products, we’re inclined to look elsewhere.

The Plath and the Globemaster are solid compasses, readily supported worldwide. The Globemaster would be our top choice in this category (as it was in our Aug. 1, 2001 test), but it didn’t pass our sensitivity test—it was off by +/- 2 degrees. We like that the Plath has a glass dome, but it’s also quite pricey with a shorter warranty period.

So, that leaves us with the Plastimo Offshore 135, which at under $200, is not only the least expensive one, but it racked up commendable scores in all areas except for nighttime viewability. Given our experience with Plastimo’s Olympic 135, however, we think it would be prudent to inspect the compass at the store before making a purchase. And that caution should apply to any compass you intend to buy.

In the 4-1/2″-and-under category, Danforth’s Corsair IV could have been a a contender, but the compass that we evaluated had a sticky movement. We set the Corsair’s lubber line on North, deflected the card 30 degrees and then released the card. The card then settled at anywhere from 356 to 005 degrees. When the movement didn’t stick, the compass turned in the best performance numbers of its peer group, but it took five or six tries (on each test) to get the card to float. We sent that compass back to Danforth for further evaluation. Our suspicion is that we simply received a unit with individual defects.

And, we gave the Corsair IV a fair rating for nighttime visibility because you have to adjust the sunshield—it has the bulb on its underside—to illuminate the back half of the card and the lubber line. In our tests, the back remained dark when the shield was fully open.

Based on our tests, the better choices in the smaller compass category are Danforth’s Constellation, Ritchie’s flat-view Navigator, and Ritchie’s flat-view SuperSport. Each of these compasses turned in very similar test scores (save for the Constellation’s viewability ratings). Both the compasses from Ritchie had Excellent viewability ratings, and both have a longer warranty than the Danforth. Though we prefer the Super Sport’s blue card, the price favors Ritchie’s Navigator, which is our choice in this category.

Also With This Article

“Selecting a Magnetic Steering Compass”

“Value Guide: Compasses”

Contacts

• Brunton, ComNav, 604/207-1600, www.comnavmarine.com

• C. Plath, 800/638-0428, www.weems-plath.com

• Danforth, 978/281-0440, www.danforthcompass.com

• Plastimo, Navimo USA, 866/383-1888, www.plastimousa.com

• Ritchie, 781/826-5131, www.ritchienavigation.com