In the April 1 issue this year, Practical Sailor presented a kick-off report about a test of 23 caulks and sealants. These products, which are so important to boatbuilders and owners, included silicone, polysulfide, polyurethane, acrylic latex, vinyl, polyether, and some combinations thereof. The brands are mostly those strong in the marine field, like 3M, Sikaflex, and BoatLife, but also include hardware-store varieties like Elmer’s, GE, and RPM products.

The testing was planned to provide answers to three important questions about these products:

1. Are they really waterproof?

2. How long do they remain elastic?

3. How strong is the bond?

To the equally important question about how long they last, PS can only refer again to the industry expert quoted in the April 1 report. When informed that there are many boats that have never even had their portlights recaulked, he said: “Fifteen or 20 years? That’s pretty long for a caulk.”

His view suggests strongly that there are lots and lots of boats overdue for recaulking and rebedding.

Because it seemed unlikely that any one product could be the most waterproof, the most elastic and have the strongest adhesive, the PS test was somewhat complicated.

The idea is to help boat owners select the caulks or adhesives that best match what they need to do—whether it’s overhauling leaky portlights, rebedding a cleat or winch, or sealing a new hatch in place. Somewhere along the line, a test for paintablility will be fed into the mix.

Since that first report last April, some readers faced with current problems have asked for interim reports on the testing. In fact, PS promised to publish intermittently any data that developed along the way.

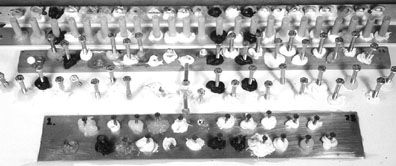

For readers wanting to know what to do now, a review of that April 1 issue might be important, mostly to examine the cure times, what you need for cleaning up, and the surfaces on which the caulks and sealants were used. As shown in the photo, they are fiberglass; wood (teak and oak); aluminum (raw and anodized); stainless steel, and brass—all used in various combinations with wood dowels, stainless bolts and washers and brass screws. Whether the materials combined make a difference in the long run may be revealed during this long-term test.

The caulks and sealants were used in globs (to provide more exposure to sun, rain, snow, etc.) instead of thin layers as they might be in most applications. Having more body meant that the curing time had to be generous. Instead of the hours, days, or weeks of cure time specified by the makers (as shown in the PDF chart and in the April 1 issue), PS gave them all four months indoors to cure in fairly pristine conditions. (After that time, it appeared—by checking for elasticity and odor—that the curing was complete.)

This first update has to do with two of the three capabilities mentioned above. They are elasticity and waterproofness. Measuring the third—adhesiveness—will have to wait, because testing will involve breaking all the bonds on both the board and the bottle rack.

Elastic Characteristics

Elasticity in a caulk is desirable if great force is to be exerted on whatever equipment is involved. For instance, a cleat used to belay a sheet is better mounted with a caulk that has long-term elasticity. By contrast, a portlight or hatch should be mounted with a caulk that has great adhesiveness and is very waterproof.

This interim report comes after the 23 samples were cured indoors for four months and then set outdoors for another four months, hung vertically and thus exposed to a half day of full sunlight, plus rain and wind. Note in the photo (pg. 1, just left of center) that three products, even after being allowed to cure indoors for four months, were so flexible that within a month the stainless bolts sagged and dropped free, two from the teak, one from the fiberglass. The products involved were Elmer’s Squeeze N Caulk and the Gloucester Company’s Phenoseal. The bolts, screws and washers set in the other products drooped but kept their grip.

Deflection measurements were made on several sets of the intact combinations of materials with the 23 kinds of caulks and sealants. As expected, the 1/2″ oak dowels best resisted bending; the thin stainless washers were the most movable.

These first comparative measurements all proved to be consistent, meaning that the percentage differences between fiberglass, wood, aluminum, etc., were the same. After that was established, fine measurements, were done on the 1/4″ stainless bolts—primarily because the bolts were the easiest to scale accurately.

Subjected to equal pressure from the side, the range of deflection on the stainless bolts was considerable—from zero to 5/8″. (When deflected 5/8″, a bolt moves about 30°.)

The ranges were broken into four groups, which are labeled on the chart as “Most,” “Moderate,” “A Little,” and “None.”

The only notable surprise in this elasticity test is that not all silicones were equally elastic, although they are more flexible than the polyurethanes, which were generally the least elastic. The greatest anomaly involved two silicone/acrylic caulks—Elmer’s Squeeze N Caulk and RPM’s Dap. The Elmer’s was among the most elastic—so elastic that, as noted above, it lost its grip on the stainless bolt. The Dap cured very hard. The elasticity results are shown in a new column on the chart.

Waterproof Characterisitcs

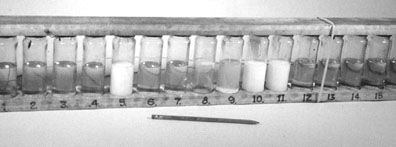

Next to be examined was the waterproofness of these caulks and sealants. As shown in the photo at left, it is being tested with small bottles of water, half filled with water, with the caps’ threads sealed inside with the 23 products. (Two extra bottles—No. 24, very tightly capped, and No. 25, firmly capped—were included as controls. On the inside of the caps are thin rubber seals.)

The bottles were half filled with water and the water levels were marked precisely by scribing the glass with a carbide tool.

As with the flat panel on which combinations of materials are being tested for flexibility and adhesion, the bottle rack was allowed to cure indoors for four months, and then hung outdoors for full exposure to a New England summer for four months. The rack was hung so that the bottles were on their sides, with the water covering half the caps. To assure equal exposure, the rack was turned over once a week. As with the flat panel, it got a half day’s sun.

Although New England’s summer (2005) was very dry, and there must have been some expansion and contraction from the heat of the day and the cool of the nights, there was little loss of water, with only a few exceptions.

The bottle sealed with Eclectic Goop lost all of its water in slightly less than two weeks. Perhaps the seal was imperfect. However, of the two control bottles with no sealant, only the one that was just firmly capped lost any water—and then only about 20%—and the tightly-capped version lost no water. It may be, then, that the silicone, which is not recommended for use under water, dissolved and allowed the water to leak out.

A few other bottles leaked very slightly (less than 10%), and four of those were sealed with products the maker identified as silicones. (Yet, four other bottles sealed with silicones lost no water.) The other “leakers” were sealed, one each, with polysulfide, vinyl, and acrylic latex. It is curious that the water turned milky in three of the four bottles sealed with what the manufacturers call acrylic latex; we take that to mean that something is dissolving.

The “sealant” results thus far are not very conclusive, other than indicating that silicone, as previously noted, is not a good choice if subjected to wetness. As with the panel test, the results of the sealing ability of these products is shown in a new column on the accompanying chart.

We expect that a winter’s exposure—with freezing and thawing, and the more drastic expansion and contraction than provided by summer’s temperature changes—may produce some fireworks…if the bottles don’t break. (To minimize that risk, the rack again will be placed on its side to give the water a larger surface to accommodate the expansion.

For the long-term exposure promised when this test was first outlined, both the panel and the bottle rack were hung outdoors again.

A final reminder: This is not a good, better, best test. It indicates only how elastic and waterproof each caulk and sealant was after curing thoroughly in indoor conditions and one summer’s outdoor exposure. Because most boats in the northern hemisphere are subjected to freezing temperatures, the winter phase of this test will be important.

Also With This Article

“Value Guide: Caulks and Sealants”

Contacts

• Ace Hardware, 866/290-5334, www.acehardware.com

• Boat Life, 800/382-9706, www.boatlife.com

• Elmer’s, 888/435-6377, www.elmers.com

• GE/Marine, 800/626-2000, www.gesealants.com

• Eclectic Products, 800/767-4667, http://eclecticproducts.com

• Gloucester Co., 800/343-4963, www.dap.com

• RPM, Inc., 330/273.5090, www.rpminc.com

• Sashco, 800/289-7290, www.sashcosealants.com

• Sika Corp, 201/933 8800, www.sikacorp.com

• 3M Scotch Brand, 888/364-3577, www.3m.com

• West Marine, 800/262-8464, www.westmarine.com