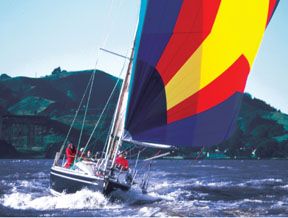

Almost every production-built boat that PS editors and contributors go aboard these days has an inventory that includes an asymmetrical spinnaker. That isn’t a statement we could have made even five years ago. The increasing popularity of asymmetrical spinnakers on cruising boats is owed in part to technological advances in these products, the inherent performance and handling advantages over their symmetrical siblings, and the ongoing marketing efforts of many sailmakers.

288

Asymmetrical spinnakers aren’t a new phenomenon by any means. Pioneering sail designers like Ken Rose, Bruce Banks, and Peter Sutter were experimenting with these shapes well before many PS readers were born. However, the advent of asymmetrical spinnakers in the cruising realm is fairly recent, and their widespread acceptance among cruisers still has a long way to go.

Asymmetrical spinnakers—”A-sails” as many sailors have grown to refer to them—are in many respects a simplification of the conventional, symmetrical spinnaker. For both sailmakers and their customers, this is good news. With an A-sail, there’s no bothering with a spinnaker pole (though many boats these days are designed and built with bowsprits for the purpose of setting asymmetrical spinnakers), and there are fewer control lines to worry about. And not only are they simpler, A-sails are potentially much more versatile than symmetrical spinnakers. They can be flown easily through a broad range of wind angles. How low and how high you can steer with these sails is partially a function of the sail’s design, the boat’s design, and the existing sailing conditions (wind speed and sea state). But generally speaking, you can make use of an asymmetrical spinnaker from roughly 50 degrees apparent wind angle down to 130 degrees.

Asymmetrical cruising spinnakers are ordinarily constructed out of nylon, due to that material’s forgiving nature. Nylon is stronger than polyester (Dacron), so it has slightly higher resistance to tearing. It also has greater elasticity, so it can resist shock-loading. Downside? Nylon sails are more prone to sail-shape distortion when the wind pipes up.

Most sailmakers favor a tri-radial panel orientation for cruising asymmetrical spinnakers. This is because that approach allows them to make the best use of the warp-oriented yarns in the fabric. (The warp yarns—those that run the length of the fabric—are pre-tensioned during weaving and thus don’t stretch as much as the fill yarns, those running 90 degrees in the other direction.) A proper tri-radial construction ensures that the major loads on the sail will align with the most stretch-resistant axis of the cloth. This, too, makes these sails more versatile.

THE SCAN

With the objective of determining what asymmetrical spinnaker products are available, and how they vary, we interviewed representatives from the major sailmaking companies in the U.S. We also touched base with a few lesser known, more regional businesses. (See “Coast to Coast” sidebar). We asked each for a quote for an asymmetrical spinnaker to be used on board a fictional Catalina 320 (standard rig, shoal-draft keel) that is kept near Norfolk, Va., and sailed primarily on the lower Chesapeake Bay. We said that this boat never races, but does occasionally cruise for several days on the Chesapeake. Other than that, it is used only for family daysails. We told them that the owner wanted a sail that would enhance the boat’s performance in 5 to 12 knots of wind, both reaching and running. As you might expect, the responses we received vary widely, both in their design specifications and in their prices. Here, in alphabetical order, is what the big-label sailmakers had to offer.

DOYLE SAILS

Based in Marblehead, Mass., with more than 50 lofts in 20 countries, Doyle Sails offers two product lines for asymmetrical cruising spinnakers: the APC (Asymmetrical Power Cruiser) and the UPS (Utility Power Sail). Chris Howes, the company’s vice president for sales and a 22-year veteran in this industry, told PS that all of Doyle’s spinnaker designs have evolved from the company’s research and design in the performance arena. Still, he said, Doyle has been building cruising spinnakers since the company was established in 1982.

“The APC, which was first introduced in 1993, is our standard cruising spinnaker. It’s a full size, performance-oriented sail, but the design has been toned down to make the sail easy to trim,” explained Howes. “The UPS is more of a hybrid between a genoa and a spinnaker, and it’s much like a Code 0.” Doyle salesmen usually recommend using the UPS in conjunction with a continuous line furler, or an ATN Sleeve. “It’s a smaller sail, usually easier to manage, and its optimum apparent wind angle is 35 to 90 degrees. With the APC, you can usually sail from 60 degrees to 130, all of that depending upon the wind and the sea state.”

The UPS sails are often built using polyester cloth, usually with Technora woven in and a film applied. The APC sails, said Howes, are all built from high-end nylon at the company’s Marblehead facility. Nylon, he says, is very tricky to seam, so Doyle deliberately has a particular person—Kim Allison—in charge of assembling all the nylon products. “She’s been doing this for a long time and is very experienced,” he said, adding that all the seams on Doyle’s nylon spinnakers are both glued and stitched for smoothness and longevity.

For PS’s particular request, Howes would recommend an APC built from .75 nylon with a Vectran luff line and Dacron leech and foot lines. The sail would come with labeled corners, color-coded edges, and a launching bag. Each sail, he told us, comes with the appropriate length downhaul, and he encourages customers to purchase sheets with shapshackle attachments.

Doyle representatives almost always recommend that a customer use a dousing sock with the APC on boats up to 50 feet, and Howes specified the ATN Spinnaker Sleeve. For boats larger than that, they specify the appropriate fixed furling system or a snuffing device. This 688-square-foot sail would cost us $2,380, he said, and carry a one-year warranty. That’s a spring price, he said, whereas sails are customarily discounted in the fall.

HOOD SAILMAKERS

We spoke with both Joe Cooper, a sail consultant at Hood Sails Rhode Island, and Tim Woodhouse, the company’s owner and president. They have each spent more than 25 years in the sailmaking industry, and both said they’d steer our customer toward the Hood Cruising Chute, which they also referred to as an MPS (multipurpose spinnaker). These sails have been in production since 1977, with ongoing refinement. Hood’s literature describes the product as having a “narrower, flatter head, which also lowers the center of effort,” compared to a conventional symmetrical spinnaker. Those features are intended to “improve handling and alleviate some of the control problems” associated with symmetrical kites.

The company also claims that the Hood Cruising Chute’s tri-radial and tri-star designs “exploit the strong warp characteristics of nylon to control shape and minimize distortion.” Both Woodhouse and Cooper were emphatic that not all sailmakers utilize nylon cloth in the same way. “We always align the vertical axis of the triangle of any spinnaker panel with the warp axis of the cloth,” Woodhouse said. That “balances the bias properties of that triangle.”

Both sailmakers said that they commonly see a different design approach on other sails that are brought in to Hood for service. On those sails, said Woodhouse, “one side of the panel is aligned parallel to the warp axis of the material, so the other side is aligned on the bias…and that causes the sail to become lumpy and unsmooth with use.”

Cooper told us that Hood’s MPS products tend to be larger than comparable sails sold by their competitors. “We use the I dimension of the rig for the luff length, and we generally use 165 percent of the LP (Luff Perpendicular measurement of the foretriangle) as the foot length. The mid girth is 90 percent of the foot length and the leech is 90 percent of the luff.”

For the average cruising sailboat, Cooper said, this sail can be used from about 65 degrees apparent wind angle in light air (5 to 7 knots, and mild seas) to about 130 degrees in winds from 15 to 18. “Depending upon how accurately the owner wants to steer and how much he wants to employ technique, he might be able to sail as low as 140.” And, “it’s perfectly acceptable to run dead downwind with the kite alone…so it’s a pretty utilitarian sail. If you have a 30-foot or 35-foot boat, in 20 knots of wind, this sail will be all the power you need.”

Woodhouse told us that the objective is to make the sail easy to use for the owner, with built-in longevity. He said the company would always recommend 1.5-ounce cloth because the tear strength is superior to .75-ounce cloth. “Three-quarter-ounce cloth tends to lose one-half its tenacity (tear strength) after about 300 hours in UV light. A sail made from 1.5-ounce cloth may weigh a little more, but it won’t lose half its tenacity in that time,” he said. Cooper added that the design emphasis would make the sail forgiving so that an autopilot could steer the boat easily with that sail up, but “it won’t be so flat that the owner can’t sail downwind.”

As for a snuffing device, Hood manufactures the Hood Squeezer. It’s not unlike the ATN Spinnaker Sleeve in that it’s a nylon tube with a fiberglass bell at the bottom.

Cooper’s quote included an MPS built with 1.5-ounce nylon fabric for $2,395 for the tri-star and $2,306 for the tri-radial, each with a three-year warranty. That price would include the Hood Squeezer or ATN Spinnaker Sleeve (usually $380 for either unit). Customers can choose from a full spectrum of colors and color combinations, and the normal delivery time is three weeks.

NEIL PRYDE SAILS

Bob Pattison, the technical director for Neil Pryde Sails, told us that he remembers making his first asymmetrical spinnaker back in the early 1980s. Based in Stratford, Conn., Neil Pryde Sails builds a line of asymmetrical spinnakers it calls Vectrix, which Pattison said can be used in winds from 3 to 15 knots (seasoned sailors would likely use them in more wind) from 55 to 150 degrees AWA. For ease of use, he explained, these sails are designed approximately 10 percent smaller than the company’s regular, full-dimension asymmetrical spinnakers. This means that the foot of the sail is about 6 percent shorter and the area in the shoulders has been diminished.

“Historically…boats were equipped with many sails,” Pattison said. “But with the improvement of rollerfurling systems, for a large percentage of cruising sailors, two upwind sails is now the norm. So adding a cruising spinnaker really fills a big void.”

Neil Pryde’s Vectrix sails are made using radial construction, with either tri-radial or true-radial panels. According to Pattison, the tri-radial sails are primarily for light-displacement boats, and most customers order true radial sails. The company designs the sail with a high clew to accommodate varying wind angles more easily and make the sail more versatile.

The company’s sales reps look first at boat type in order to determine what kind of asymmetrical spinnaker to build. “Spinnaker size governs the top end of the sail’s wind range, so if you go with a maximum size, people won’t use the sail quite as much. Another important factor is locale.”

Pattison said his company would recommend a 165-percent asymmetrical spinnaker built with a combination of 1.5-ounce nylon in the high-load area of the luff and .75-ounce cloth in the aft section of the sail. He said this would result in a “better-flying but stronger sail overall.” He also sent along a “Cruising Spinnaker Overview” as well as a how-to article on the techniques of managing asymmetrical spinnakers, and instructions for using the company’s color selection program.

234

He recommended that we also purchase a dousing sock, saying that Neil Pryde supplies the ATN Spinnaker Sleeve for boats 45 feet and longer and the Chutescoop from V.F. Shaw for boats shorter than 45 feet ($250 for the Chutescoop and $400 for the ATN). Instead of a strop to fit around the furled headsail and keep the spinnaker tack close to centerline, Neil Pryde prefers its own version: parrel beads. These sell separately for $47, but are usually included in the price of the Vectrix sail, which would be $1,573 in this case. Add the dousing sock, and that’s $1,823 for the 744.76-square-foot sail, which comes with a two-year warranty on material and workmanship. Delivery time would be three to four weeks.

NORTH SAILS

In business for over 30 years, North Sails is the largest sailmaking firm in the world, with franchise or affiliate lofts on five continents. PS spoke with Jack Orr, a 20-year veteran of the industry and a sail consultant who operates out of the company’s office in Milford, Conn.

Orr told us that North has refined its asymmetrical cruising spinnakers into three product areas that are designated using nomenclature from the racing arena: The company builds G-Series gennakers in G-0 (relatively flat for tighter angles), G-2 (largest and most powerful), and G-3 (smaller, flatter, and more versatile than the G-2) configurations. These sails are made using North’s proprietary nylons, Norlon 70 or Norlon 250, in cloth weights of either .75-ounce or 1.5-ounce.

Two things distinguish North’s A-sail products, Orr said. “We make so many more of these sails than anyone else that we’ve got volumes of experience. And, our technical approach is both sophisticated—with wind-tunnel testing, and finite element analysis on computers—and pragmatic—we get a lot of feedback from our extensive network of sailmaking professionals who spend a lot of time on the water. That experience, derived from developing, building and using racing sails gives us the knowledge to make a cruising A-sail more stable and therefore easier to trim.”

Two days after we spoke with him, Orr sent us an e-mail that contained quotes for all three of the G-Series models, but said that the best choice for our customer would be the G-3. “It has the most versatile shape, being flat enough to reach well and a little smaller in size, making it easier for shorthanded sailing. I would recommend .75-ounce Norlon (nylon) cloth for the body of the sail with some 1.5-ounce in the high-load area of the luff and head. These sails can generate more loads in the luff than a conventional kite, so we usually offer a step-up cloth weight,” he explained.

This sail, which would measure 796 square feet, would cost $2,646, and would include the Snuffer ($370 if purchased separately), an R-F Tack belt (similar to the ATN Tacker), as well as spinnaker turtle bag. North also provides a CD ROM video that explains the basics of flying a gennaker and using the snuffer.

North’s prices change seasonally. “The best time to buy a sail is always late-summer and fall.” Our quote, he told us, reflects a September price. After a 50-percent deposit is received, the customer is directed to the company’s Color Me Fast program online where he will be guided through the color and layout process. Delivery time depends on the season, but it will usually be somewhere from six to 10 weeks.

QUANTUM SAILS

Based in Annapolis, Md., and just now completing its first decade of existence, Quantum Sail Design Group is a relative newcomer to the industry, but that statistic belies the depth of experience shared by this company’s principal players. The organization now boasts 45 lofts on five continents. PS contacted David Flynn, a Quantum sail consultant with over 20 years experience.

Flynn explained that Quantum’s asymmetrical spinnakers for cruising applications—the Vision Series—are built in three styles. Like North, its numeric names derive from racing, with V0, V3, and V5 models that graduate from close reaching to broad reaching capabilities as the numbers increase. Flynn credits some of this to the company’s direct involvement in sail development for the America’s Cups of 1992 and 1995.

“The courses at that time featured reaching legs, so that spurred a lot of A-sail development and was the impetus for more efficient sails,” said Flynn. “One of our company’s first projects was a joint effort with the University of Maryland’s Department of Aerospace Engineering. They wanted to analyze off-wind sail shapes, specifically spinnakers, and that gave our designers access to their wind tunnel…Despite claims to the contrary, computer modeling or finite element modeling of spinnakers is very difficult, and virtual wind tunnels just aren’t that accurate.”

Stressing that the company is a custom sailmaker with essentially no off-the-shelf products, Flynn said he would recommend a V3 for our Catalina 320 owner. “Since this boat has a relatively modest J dimension, I sized this sail using 180 percent of J for the foot, making it a full size sail. Because the owner sails in the Chesapeake Bay, and the goal is light- to moderate-air reaching and running with an emphasis on broader, not closer angles, that should work out well. The mid-girth measurement (SMG) would be 95 percent of the foot since this is not a pure runner, but a sail that will see plenty of reaching.”

Flynn said that the cloth would be .75-ounce Challenge Fleetwing nylon, which should be strong enough for the intended range of use. In fact, he said, .5-ounce cloth would be suitable, so the .75-ounce option would provide “a margin of error.” And Quantum, he explained, does not recommend fixing the tack to the headstay (with the use of something like an ATN tacker). “This harks back to the day when cruising spinnakers were more like cut-off symmetrical sails with short luff lengths that flew high up off the deck. Modern asymmetricals have a long luff, with the tack right at the pulpit level for close reaching, so there is little need for a tacker.”

The price Flynn offered for this 716.8-square-foot sail—$1,933 (not including an ATN Spinnaker Sleeve, which would add $416)—reflects Quantum’s fall prices. It would be roughly 10 percent more if purchased another time of the year. The sail would come with a turtle bag, and the customer would be able to choose from a full range of colors. Typically, said Flynn, the sail would be delivered by a sail consultant (where possible), who would install and hoist it on the owner’s boat while going over the fine points of its setup and use.

UK HALSEY

PS contacted Adam Loory, the general manager of UK Halsey International, who works out of the company’s office in City Island, N.Y. Loory told us that UK Halsey first began building asymmetrical spinnakers in 1975 when the firm was operating under its original name, Ulmer Sails. According to Loory, the company’s chief designer at the time—Owen Torrey—had perfected the radial head design for symmetrical spinnakers, so it was a logical extension for him to apply that to an asymmetrical application. Though UK Halsey’s asymmetrical spinnakers still utilize tri-radial construction, and the sails are still marketed under the original name—Flasher—the designs have evolved considerably since then.

UK Halsey, said Loory, essentially builds two lines of asymmetrical spinnakers for the cruising market, the Flasher and the tri-radial Flasher. The former uses horizontal panels in the middle of the sail, whereas the latter has only radial panels. “A Flasher is the least expensive model,” said Loory. It’s a more economical sail that’s suitable for small boats up to 30 feet. “The tri-radial Flasher is more sophisticated, and it carries the loads better, especially when reaching…The development of the tri-radial is what we call the Matrix, with no straight horizontal panels in the middle of the sail. All the seams are rocked to follow the load lines. Essentially, all boats over 40 to 45 feet should be using the Matrix construction because it’s stronger and holds the shape better.”

Loory keenly stresses the importance of familiarizing customers with the proper use of the product. “If you don’t teach them how to use it, the sail will stay in its bag, and then no one benefits.” Loory and his colleagues at UK have developed several useful teaching tools, including instructional videos for jibing and dousing asymmetrical spinnakers. And he highly recommends the use of tapered spinnaker sheets with low-profile shackles like Tylaska T5s instead of knots, because these can help a less experienced sailor perform jibes easily. “Thick sheets will weigh down the clew and knots like bowlines will get hung up on the shrouds and the forestay during a jibe. All of that simply leads to frustration on the part of the owner.”

Tripp Fellabom from UK Halsey South in Charleston, S.C., responded the same day of our request. (The Annapolis, Md., loft would normally serve a Chesapeake-based boat, but PS’s researcher was based in Charleston, so the quote request went there). Fellabom sent us a quote specifying a 945.96-square-foot Tri-Radial Flasher to be built out of .75-ounce cloth. The sail would cost $2,320, and Fellabom recommended we purchase an ATN Spinnaker Sleeve ($436) and an ATN Tacker ($80). He said that a tack line and tapered spinnaker sheets would add $117 to the package for a full price of $2,953. We’d have to make a 50 percent deposit to place this order, and normal delivery time would be three to four weeks. The sail, he said, would come with care instructions and warranty information. “When we delivery every A-sail,” he told us, “we also give the owner a DVD called ‘The Cruising Spinnaker A to Z.’ It tells you everything you will ever need to know about these sails.”

ULLMAN SAILS

Known principally for the success of its one-design racing sails, Ullman Sails has been in business for over 30 years. Founder and proprietor Dave Ullman is a well-known competitive racing sailor with a slew of championships to his name. What was once a small family business has expanded to a company that now has 24 lofts on four continents.

288

Rather than offering a stock line of cruising sails, Ullman Sails prefers to custom-make its products according to the clients’ needs and specifications. To fulfill that directive, the company has two distinct lines of cruising sails: Coastal and Bluewater. The underlying emphasis on the former is value; on the latter, it’s durability and strength.

We logged on to the Ullman Sails website (ullmansails.com) and registered our request for a quote. The company routed this to its loft in Deltaville, Va., and about a week later, we received a fairly detailed response from Jerry Latell, the manager of that facility.

For our Catalina 320 owner, Latell proposed to build an all-purpose radial-cut cruising spinnaker from the company’s Coastal line using .75-ounce nylon from Challenge for the sail, which he said offers the best combination of quality and value. “There are size options,” he said, “and I generally build spinnakers to match the boat, skipper, and sailing conditions, which usually falls into the range of 160 to 180 percent of the boat’s J measurement. The Catalina 320 has a relatively large masthead fore-triangle, and for sailing on the Chesapeake Bay, I would recommend 170 percent, so the sail would measure 977 square feet overall. The design would favor the reaching side of the all-purpose formula. A reaching spinnaker has a narrower head and often narrower mid girths that allow it to be used at closer apparent wind angles. This sail would be good from about 80 degrees apparent wind angle in light air to almost 160 degrees off the wind in heavier winds.”

The sail would run us $2,332.

Latell told us that in addition to a strop like ATN’s Tacker, almost all of the cruising spinnakers his loft builds are delivered with spinnaker sleeves. In our case, he said he’d specify ATN’s Spinnaker Sleeve.

“If a customer is experienced with using a cruising spinnaker, then they’ll often just come to the loft and pick up the sail. But if he were a novice we would provide a training test sail as part of the sail purchase. During that, we’ll demonstrate rigging, handling, and trimming the sail. And many of our new customers will have us rig the sheets and tack lines as part of the sail purchase.”

Throw in the ATN Sleeve ($471), the Tacker ($110), and the purchase would total $2,913. The sail would carry a one-year warranty.

CONCLUSION

Although we would not purchase sails based solely on price, our market scan provided much useful information. The pricing could be broken down into three groups. Only Neil Pryde’s sail/snuffer combo came in under $2,000. In the mid-range, Hood (tri-radial) and Quantum priced a sail and sock just over $2,300. The Hood (tri-star), Doyle, North, UK Halsey, and Ullman rounded out the high end at $2,600-plus. The sailmakers listed in “Coast to Coast” offered very competitive prices, some beating Neil Pryde’s. With many sailmakers, these prices can vary from 10 to 20 percent during the year. Late summer and fall are generally the best times to buy.

Regardless of which sailmaker we settled on, we’d seek out the opinion of sailors in our area using a similar sail, and we would request a cloth sample. PS intends to carry out fabric and design testing of these sails, which should help narrow the field.