Bottom Paint Woes When my boat was hauled out in August 2007, there was extreme fouling in some areas (see photo at right). Two coats of Pettit Hydrocoat were applied in March 2006, and the boat remained in the water during the winter (Chesapeake Bay, between Annapolis and Baltimore, Md.). By March 2007, the growth was slowing the boat. When the water was warm enough to dive, I found several areas badly fouled, including from the waterline to about one foot below all around, the rudder 288 and skeg. I spent two hours scraping the rudder and skeg and around the waterline. Ive been using Hydrocoat for the last six seasons, painting the bottom every other year when hauling out. No significant problems before. My boat requires approximately two gallons of bottom paint. Growth showed only in those areas in which I applied the second gallon of paint (the rest of the bottom looks fine, as shown in the pictures). I told Pettit that what concerned me was that everything indicates that the second gallon of paint failed. Because of that, I now have to haul out the boat, scrape the bottom, sand the bad paint, and repaint. If a bad batch of Hydrocoat is the cause, I feel Pettit should provide me with an adequate remedy. According to Pettit, fouling in the Chesapeake was bad last year and even the best paints would be extremely unlikely to provide a second year of protection under these conditions. The company representative said that Hydrocoat can provide sufficient antifouling over two seasons, but that no paint manufacturer provides any warranty for successive seasons. They also offered to give me two gallons of paint. Alberto Cogut Unfortunately, convincing a paint maker or boatyard that you are due haulout and prep costs after more than one year of immersion in saltwater is an uphill battle. We know, weve tried. It was good to learn that Pettit agreed to send you two new gallons of Hydrocoat. We also understand how upsetting it can be when a paint that has always served well fails sooner than expected. A bad batch of bottom paint is not impossible but would be difficult to prove here. In our panel tests, we have found that only a few paints consistently do well every year, and these top-rated paints typically perform well in the field. Some years, the favorites do worse than usual in the panel test and some harbors prove extremely troublesome in the field. None of the Hydrocoat panels in our recent tests have allowed hard growth in less than 12 months, but these panels stay put and are not scrubbed. The sections of your hull that received the second coat of paint-near the waterline, leading edges of appendages, and the bottom of the keel-are sections that see more sunlight or water friction and tend to fail first, even with a second coat. Hydrocoat consistently ranked well among our water-based soft paints-although it did not reach our most recent top 10 for long-term protection (October 2007). Water-based bottom paints are becoming increasingly popular as people start moving toward low-VOC alternatives. We plan to pit Hydrocoat against a comparable water-based competitor in a head-to-head field test (see pages 34 and 35) and report on it. Tank Monitor Test Would you consider reviewing liquid tank monitors? We have unknowingly lived on the edge several times by not realizing how full our waste tank was. Luckily, it was pumped before we went over that disastrous edge. This spring I installed a Fireboy-Xintex tank monitor in my waste tank. It is not a product that I would recommend to others as it frequently clogs. Xintex has since sent me a new, improved sensor, but I would like to see a review of all other products on the market. Rick McCowan

1975 Dufour 34

Upper Chesapeake Bay

Mattapoisett, Mass.

We are in the midst of testing three different external tank sensors for holding tanks, and that test will be followed by the internal types like the Fireboy-Xintex you describe. While were on the subject of tank level indicators, we have also ordered the new composite propane tanks available through Trident Marine (

www. tridentmarine.com). These tanks are translucent, allowing you to check the fuel levels visually.Ethanol Issues

My mechanic discovered a gummy substance clogging the carburetor on my Tohatsu 9.8 4-cycle outboard. He said he is seeing this more often now that ethanol is being added to gasoline.

I contacted the manufacturer of the plastic gas tank built into my sailboat (in 1999), and they said there would be no problem with up to 15 percent ethanol, but Im a little suspicious. Where else could the gumminess have come from?

My mechanic also said that ethanol somehow causes water to be absorbed and that, though the rule used to be to fill the tank for winter storage, now an empty tank is best.

Does

Practical Sailor have any information concerning problems with 10-percent ethanol?Michael Hoffman

East Greenwich, R.I.

We reported on the problems with ethanol blends in the January 2007 issue. The article is now online in our Tools and Techniques section at

www.practical-sailor.com.Ethanol is a powerful solvent effective at loosening any gunk that has built up in your fuel system. It also can cause water buildup in the tank. Without proper filtration, these contaminants eventually can reach your carburetor and possibly harm your engine. You should check with Tohatsu regarding any specific recommendations they have for dealing with ethanol-blended fuel. You should also check your fuel lines to make sure they are rated for ethanol (stamped SAE J1527).

Ethanol may harm rubber and plastic parts, including plastic bowls on some older filters. We are not aware of any problems associated with plastic tanks that are rated for ethanol-blended fuel.

As far as storage goes, we are recommending that when it is safe and practical, try to empty your tank of ethanol and either replace it with high-octane, non-ethanol blend, or leave the tank empty. Otherwise, fill the tank with ethanol and a storage additive.

Matching Gelcoat

I have just purchased an older Bluenose 22. Are there different brands of gelcoat, and do you have any information on those that perform best?

Charles Murray

Mackinac Island, Mich.

The best gelcoat alternative for any boat is the product that the builder used when the boat was molded, or a replacement resin specified by the original gelcoat manufacturer. Colors change due to UV and other chemical factors, but the best starting point is with the original color and chemistry that the manufacturer used. Perfect matches are hard to achieve, and one of the reasons why topside painting has become so popular. Many owners do touch-up work with polyester putty that they use to level gouges and then sand smooth, finishing off the repair with an automotive-type spray paint that matches or comes very close to their boats current finish. The final step is to wet-sand overspray with 600 wet/dry paper and wax the repair. This is a valid approach if matching the existing gelcoat color becomes too difficult. If better-than-new gloss and shine are desired, a costly professional linear polyurethane spray finish will deliver the results.

Inflatable PFD Update

288

The most recent

Practical Sailor that I can find that addresses inflatable PFDs is the Oct. 1, 2004 issue. Is there a more recent test that I have missed? Have you ever tested or are you familiar with Revere products? The best life jacket in the world is of no use in the locker, but thats where my SOS inflatable stays because its so uncomfortable to wear.Tom Wolanzyk

Charlevoix, Mich.

The October 2004 evaluation was followed with an update in the April 2006 issue. We are currently collecting the latest breed of inflatable PFDs, and the Revere will be among them.

Life Raft Lifespan

Prompted by your series on life rafts, I dropped by my local life raft re-packer recently for a chat. He has re-packed my Avon eight-man life raft a number of times. I asked him what raft he suggested I invest in, feeling that at 15 years old, perhaps this raft was destined for the backyard as a kids pool.

I was surprised, not to say gratified, with his response.

He said that my 15-year-old Avon is better made than most of the newer rafts and that he is repacking rafts that are 30 years old. According to him, they still have many more years of potential use. He also said that some of the newer rafts are poorly constructed, with much less robust fabrics He could have sold me a newer

288

raft, but he didnt. He recommended I just re-pack my existing raft.

David H. Lyman

Rockport, Maine

In our view, recreational life raft construction is improving, not getting worse. Recreational life raft manufactures now have formal guidelines to use when building rafts. The International Standards Organization has promulgated detailed structural standards that not only stipulate the strength of the material used, but also define how ballast bags, canopies, and other crucial aspects of a raft should be built.

Older rafts deteriorate chemically and seam cement can lose much of its adhesive quality. The consensus among commercial and recreational raft service agents is a 10-year lifespan and with careful storage and regular inspection, the limit may be pushed to 15 years. Older rafts may hold air when inflated, but the big gamble is how much of their original strength remains intact. Its important to remember that when conditions are bad enough to claim a 20,000-pound, 40-foot vessel, all must be in A-plus shape for a crew to survive in a 100-pound fabric structure that will be exposed to the same tempest. The latest line of recreational life rafts built to ISO and ISAF standards are better than ever.

Reading The Fine Print

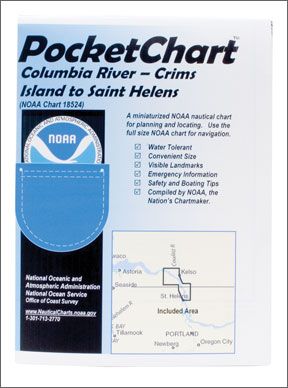

I suggest you consider warning your readers about NOAAs PocketCharts. I sail a 28-foot boat with a 4-foot, 10-inch draft on the Columbia River, which is often crowded with traffic from car transports, other large ships, and tug-and-barge combos. I need a good chart in the cockpit that I can read quickly while getting through this traffic.

I ordered a NOAA PocketChart (see photo) from

www.noaachartsonline.com. What I received is essentially useless for me, and I believe for most any person over 50 years of age. The scale is way too small. Using a magnifying glass, I could see the rough edges on the type, which means that it will blur if I photocopy and enlarge to make the chart more readable. And this product is not returnable.Donald H Sparks

Portland, Ore.

Hull Cleaner Field Test

288

Regarding your recent review of Barnacle Buster (May 2007), for hull cleaning: My marina in Westerly, R.I., recently began carrying a product called Rydlyme (

www.rydlyme.com). I gave it a try on a fairly bad case of those small white conical barnacles that had sprouted at the waterline.Story short, the stuff works. It may take some extra scrubbing, but it was a much more pleasant product to work with. No choking, tearing fumes, and no third-degree skin irritations.

Its a little more expensive than the On-Off or equivalents, but benign characteristics, bio-degradability, and overall stellar effectiveness make it well worth the extra money.

Capt. David Shepherd

Hope Valley, R.I.

Stainless Steel Chain

In your recent article on mooring chain (September 2007), you assert that work hardening needs to be considered in mooring applications, and we agree with that. But then you go on to say that “(it) involves a serious leap of faith. Stainless steel sees so little use in high-load-cycle applications precisely because it does not hold up as well to this use as materials with higher ferrous content.” We believe that last conclusion is worded far too generally to be accurate.

There are a lot of different applications that involve stainless steel in high-load-cycle applications. For instance, stainless chain is used to suspend and hold

288

submersible sewage pumps that cycle on and off for very extended times, in a much more corrosive environment. Most sailing vessels have standing rigging that is either completely or predominantly made up of stainless steel.

Roman F. Striebel

CEO Suncor Stainless

Submerged stainless steel is more galvanically active than mild (low carbon) steel. Sailboat rigging is not supposed to be submerged. When stainless steel swages or fittings associated with a bobstay are immersed, bad things can happen. The same goes for stainless bolts and brackets below the waterline, which is an oxygen-reduced environment. Add the hydrogen-sulfide-rich anoxic realm of a muddy bottom, and stainless steels place on the galvanic table takes another nasty jump. Rusty, low-carbon steel warns us of impending failure. Stainless steel is not always so polite.