As I plumb the archives for holding tank replacement info, I find excellent related articles (PS, February 2012, March 2012, and April 2012); all remind me to build in good ventilation. However, I am unable to find guidance on the merits of ventilation fittings. These stand at the interface of tank gasses and other contents trying to get out, and the marine environment trying to get in. Issues such as shape, location, mounting, and materials concern me. Can you bring some fresh air to vent fitting merits?

James Lavery

Hoku Kea, Southern Cross 31

Seward, Alaska

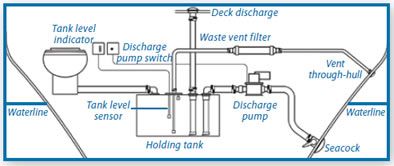

When it comes to plumbing holding tanks and their vent fittings, there are a few rules of thumb that we recommend following:

Holding tank vents should be plastic, not metal. There are no metals that deal well with the corrosive gases being vented; all metals will either discolor or pit in this application.

A simple through-hull design is best as it allows you to backflush the vent using a garden water hose. Follow the American Boat and Yacht Council (ABYC) standards for installing a through-hull above the waterline (section H-27), and be sure to include a beefy backing plate. Adding a seacock (PS test, Sept. 1, 1994) to the setup isn’t necessary, but it would add security.

You can find guidance on installing through-hulls and seacocks in Nigel Calders Boatowners Mechanical and Electrical Manual, on the BoatUS website, www.boatus.com, and on the PS website under Fair Through Hull Fittings.

Clam shell vent covers should be avoided, but the worst type of vent for this application, in our opinion, is the chrome, 5/8-inch fitting with an integral screen and cover. Commonly used on power boats, this style of vent fitting is too small (it should be at least an inch); the screen can clog up; and the cover inhibits backflushing.

A holding tank vent must be located above the heeled waterline (usually led from a high point in the plumbing). Use commonsense when choosing the location: Place it away from the cockpit and galley ports. (Weve seen vents installed in some creative and troublesome places-like an anchor locker aboard a Tartan 34 and upwind of the cabin on a PDQ32-and nothing ruins an appetite like a holding tank off-gassing!)

The vent line should originate from the tanks centerline, both fore-aft and port-starboard, to avoid clogging from sloshing liquids.

If your vent is properly sized (at least 1 inch; the bigger, the better), cross-ventilation is not usually necessary. However, if you use smaller vents-or want added ventilation-you can plumb two vents into the holding tank and run them to opposite sides of the boat.

There should be no electrical components in the tank because of the risk of methane gas explosions. This is a Coast Guard regulation-and it may be obvious-but its worth mentioning.