Photo by Benôit Sthichelbaut

288

Several themes prevailed at last fall’s International Boatbuilder’s Exhibition (IBEX), one of the marine industry’s premier insider conferences. One was hybrid boat design, and a second was the application of lithium battery technology to high-current electrical applications. “Hybrid” and “lithium” have become buzzwords in the marine industry as we look forward to green technologies, not only with boats but in all manner of electrical supply and propulsion systems.

In light of this latest trend toward lithium-ion batteries in marine applications, Practical Sailor decided to explore the products currently on the market, separate fact from fiction, and get a clearer picture of where lithium battery technology is headed in the next few years. With all the hype about lithium-ion batteries, we expected to find multiple manufacturers jumping into the marine market, but in fact, we only found four companies actively targeting the marine sector. One of those companies, Corvus Energy of Vancouver, B.C., has delved only into the commercial side of the industry.

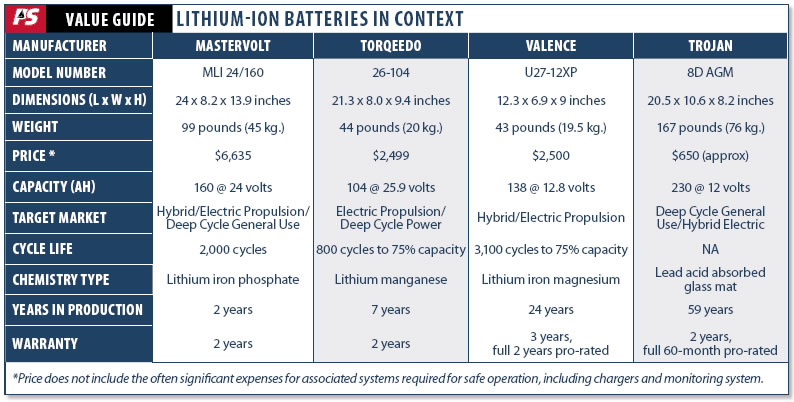

Of the three major players in the recreational marine market, two are familiar names to PS readers. The Dutch company Mastervolt was recently recognized in our inverter-charger test (PS, March 2010). The German company Torqeedo, known for its breakthrough electric outboard motors (PS, January 2011) now has a 24-volt, 104-amp hour, stand-alone battery available. Valence Energy Systems offers several battery packs in both 12-volt and 19-volt configurations. Although some sailors have found other sources for lithium-ion batteries, these batteries are not aimed at the marine market.

Why lithium ion?

Scientists and engineers have been trying to improve batteries since Alessandro Volta developed the first so-called “voltaic pile” over 200 years ago. Cheaper, safer chemistry, greater power density, a faster recharge rate, low maintenance and greater cycle-life have always been the goals and will continue to be the driving forces from a design perspective. The need for storing electricity and making it portable is a fundamental fact of life in today’s age.

Early on, scientists knew that lithium is the lightest of all metals and has a very high electro-chemical potential. Lithium provides the highest energy density for its weight; in fact, depending upon the specific chemistry used, lithium-tech batteries can easily achieve two- to three-times the power density of conventional lead-acid or nickel-cadmium batteries. Also early on, scientists learned another important fact about lithium metal: It is inherently unstable. Early efforts to create rechargeable battery cells resulted in frightening fires and extreme over-heating issues. The answer to that problem was to move toward the lithium-ion, which is not metallic and considered safe as long as certain, very strict cell control parameters are met during discharge and recharge. Safety is also dependant to a large degree on the actual lithium-based chemistry used.

Sony Corp. is credited with being the first to bring the lithium-ion battery to mainstream commercial use in 1991. But the learning curve certainly didn’t stop there. The stories of people burning their knee caps as the lithium batteries in their laptop computers went into thermal run-away are not urban myths.

In spite of these early growing pains, technology has evolved to the point where the current state of the art is lithium-ion. There are several reasons for this:

· High energy density compared to any technology we are aware of today.

· Essentially no “break-in” charge cycling is needed.

· Relatively low self-discharge (approximately 3 percent voltage drop per month), especially compared to the nickel-based chemistry it is replacing, Nickel cadmium (Nicad) and nickel metal hydride (NiMH).

· Low maintenance.

· No “memory” issues such as those that plagued Nicad technology

· Much higher recharge efficiency

The Lithium Difference

As interest in all things eco-friendly and hybrid and total electric propulsion concepts continue to evolve, one of the obvious questions is: “How are lithium batteries different from the batteries on my boat right now?”

The differences are many, and they are by no means obvious. We list some of the advantages above, but here are some of the disadvantages we face as we employ this technology:

· Lithium battery cells require “protection” circuitry to maintain carefully controlled balance in both voltage and amperage between the cells that make up a battery. One engineer weighing in on a lithium-battery forum who has worked extensively on lithium technology for the airline industry states that a variation of as little as 100mV between cells during discharge can cause major problems.

· Lithium batteries are subject to accelerated aging if not properly cared for. A fact that is often ignored and is somewhat counter-intuitive is that storing lithium batteries at 100 percent state of charge will actually reduce their life cycle potential. Cycle life, especially at the price of these batteries at this point in time, is a major issue. Without maximum cycle life, the return on investment for this technology is seriously in question.

· Battery storage temperature is another critical concern with lithium technology. Engineers have learned that lithium batteries that are partially discharged and stored in refrigerators last longer. Tesla Motors, for example, has studied these matters extensively and has integrated a liquid cooling system for its battery pack to help maintain favorable temperatures and maximize battery cycle life.

Lithium-Ion Chemistry

Perhaps one of the most confusing issues surrounding lithium battery technology is that the different manufacturers are using different types of chemistry. Some use a lithium-cobalt or lithium-cobalt mixed with nickel technology, which is generally considered unsafe for use in larger battery configurations like those we see in marine applications. Others use lithium-iron phosphate or lithium-manganese or lithium-iron magnesium. Still others will use an even more complex lithium-nickel-manganese-cobalt blend, which supposedly enhances the potential current density. A recent addition to this chemical potpourri is a lithium-ion-iron-sulfide chemistry, which one British company is claiming will provide 1.6 times the energy density of existing lithium batteries at half the cost. Time will tell. In all of our research, we found that there is no common ground in all of this. Each manufacturer is walking a fine line between power density, safety in application, and cost.

Much has been learned from the automotive sector in all of this, and they certainly have a more business-friendly critical mass to support research and development than the recreational marine market.

With that in mind, you may be asking yourself why your brand new Toyota Prius is still using 15-year-old nickel-metal hydride technology for its hybrid drive power. The truth is, Toyota intended to use a lithium-ion battery pack in its 2010 models, utilizing nickel-based chemistry. It turned out that although they were able to reduce materials costs significantly, they discovered that the production process was quite complicated and added too much cost to the battery to make it economically viable. So, Toyota shifted gears, and stuck to the tried-and-true NiMH battery pack it has been using with good success—for now. Plans are to introduce a tri-metal lithium battery pack with their 2012 model year using a cobalt, nickel, and manganese blend.

courtesy of Veolia Environnement

530

Lithium in Boats

So far, we’ve only seen lithium-ion batteries used in high-end hybrid, all-electric, or alternative power applications on boats. Even among that small niche, it is more common to see AGM batteries because of the high cost of using lithium-ion. With that said, we have seen major price adjustments in lithium batteries in just a few years. Mastervolt, for example, introduced its MLI 24/160 lithium-ion battery several years ago at a nearly $8,000 list price. That same unit today costs $6,650, still nothing to sneeze at, but moving in the right direction.

Regulatory Issues

One of the regulatory issues that is driving interest in electric propulsion has nothing directly to do with the batteries themselves. For several years, some European countries have excluded the use of internal combustion engines on lakes and inland waters. This has driven up interest in electric propulsion, and it has certainly helped the Germany-based Torqeedo. Its lithium-ion battery is a spin-off from its core business, which is a growing line of highly developed electric outboard motors, all powered by lithium-ion batteries. These same regulations are now moving to the U.S. and several of the classic inland pontoon boat manufacturers have embraced the Torqeedo motors as original equipment.

Photos by Ed Sherman

288

Meanwhile, there are no standards or federal laws that specifically address lithium-ion use or installation on recreational boats. The American Boat and Yacht Council (ABYC) is considering development of some guidelines in this area, but at this time, nothing has been cut in stone.

Nor are there any U.S. Coast Guard regulations. We suspect that the USCG will approach Li-ion battery standards as they have similar issues: Wait to see what the ABYC comes up with first. For now, the 40-year-old USCG regulations that apply to basic lead-acid battery technology installations are the only mandatory requirements guiding field installers. This is a pretty frightening circumstance when we think of the potential here. As we mentioned, these lithium batteries have extremely high power densities, meaning that for their size, they can pack a very serious punch. One of the concerns is over-current protection of battery banks on boats in the event of an electrical short-circuit at or near the batteries. The available short-circuit current at these batteries is extremely high—in the thousands of amps—and there are no guidelines that specifically address short-circuit current protection.

The potential for disaster is real. We found some Valence U-27 lithium batteries available on eBay at a $1,500 “Buy it Now” price. Combine that temptation with the unfiltered accolades of the blogosphere, and it is only a matter of time before someone replaces all of their standard lead-acid batteries with high-power lithium-ion batteries, believing it is the right thing to do. The following point can’t be overemphasized: Proper use of lithium-ion battery technology on boats means buying into a system that includes consideration for not only safe installation, but also proper load management, over-current protection, and recharging while at rest and underway. Also, achieving the maximum lifecycle from a lithium-ion battery requires careful provisions during seasonal lay-up periods—an item that you don’t see advertised in the boat show literature. If the off-season maintenance routine is not carried out correctly, this could have a significant impact on the actual cost per watt-hour of electricity used during the life of these batteries.

The Players Today

As already stated, we could find only three companies that have made any significant inroads into the recreational marine marketplace, and we identified one company that is working in the commercial marine market. This seems a bit odd, because if you Google through lithium battery manufacturers, you will find hundreds even thousands listed, primarily in China, but with a main focus on other industry sectors, predominantly batteries for electronic equipment. The need to keep all those iPads and iPods powered up is a really big deal from a global perspective.

Let’s focus on the three players in the recreational marine market: Mastervolt, Torqeedo, and Valence Energy. Each of these companies offers very different products and has taken slightly different directions in how it has approached the recreational marine market.

Mastervolt

Mastervolt, based in Holland, prides itself on its ability to stay at the leading edge when it comes to designing and bringing to market innovative, integrated power-supply systems. Practical Sailor has certainly seen that innovation in any product comparison tests we have done in recent years where Mastervolt had a product to offer. As leaders in this area, it stands to reason the company would be among the first to offer up a high-capacity battery system using lithium-ion technology. Enter the MLI 24/160.

Mastervolt systems end up on a lot of high-end vessels and land-based coaches all over the world. Many of their customers have high electric power demands and power-to-weight ratios are a never-ending design concern. Lithium-ion can help there. Further, the company’s acquisition of Bellman, an electric-motor drive company, last fall seemed to create a natural match to expand into the electric propulsion sector of the market.

One of the fundamental design parameters around any electric propulsion system is weight reduction, particularly on a sailboat. The increased power-density of the lithium-ion battery is a major contributor toward making these sorts of propulsion systems a reality for the mainstream. Furthermore, when compared to traditional battery technology, lithium tech batteries can be discharged much further than their lead-acid counterparts, so they are effectively providing more power for each charge-discharge cycle. Mastervolt claims its new battery delivers 60-percent more power per cycle than a similarly sized lead-acid battery. It also spotlights the battery’s extremely fast rate of recovery. The main limit on the rate of recharge, says Mastervolt, is the charging capacity of the onboard charging system.

Mastervolt has chosen lithium-iron phosphate as its cell chemistry. Based on our research, this chemistry is among the safest under the lithium battery umbrella. To further enhance safety and help control cycle life, Mastervolt includes an integrated battery management system (BMS) in each battery. This system continuously controls cell balancing during charging, discharging, or at rest. If the user chooses, and it is recommended, the batteries can be connected via a MasterBus network to one of Mastervolt’s MasterBus-enabled battery chargers. Mastervolt claims that this “system-matching” will add approximately 5-percent more effective capacity. Also, the system lets you monitor battery state of charge via a remote panel. In tune with hybrid or high-voltage DC electric drive systems, the batteries can be series-connected to achieve as much as 250-volts DC and can be parallel-connected to increase amp-hour capacity to a virtually unlimited level. This, of course, is good and potentially bad, as discussed earlier. This is one of the reasons some standards development is in order, in our view.

Mastervolt enjoys an impressive customer list that is working with lithium battery technology at one level or another. Practical Sailor readers will certainly recognize some of Mastervolt’s lithium-ion customer base: Pearson Yachts, Baltic Yachts, Swan, X-Yachts, Catana, and Outremer, to name a few.

Bottom line: Mastervolt does a good job of balancing performance expectations with safety. Sailors interested in hybrid propulsion should keep an eye out for field reports (and updates in Practical Sailor) as more of these systems go into service.

Photos by Ed Sherman

288

Torqeedo

Torqeedo is based in Starnberg, Germany with offices in Crystal Lake, Ill. Practical Sailor has tested two of the company’s portable outboards, most recently the T-1003 (January 2011). Several years ago, the company introduced what are to date the most innovative electric outboard motors anywhere. They are powered with lithium-ion batteries; lithium-ion manganese, specifically.

Although Torqeedo is marketing its new standalone Li-ion battery pack toward smaller boats (as opposed to the larger boats with hybrid or electro-propulsion that Mastervolt is attempting to woo), some makers of larger boats are embracing it as well. Godfrey Pontoon Boats, one of the oldest U.S. builders of pontoons, now offers a Torqeedo power package, and its dealer network seems to be embracing it.

Torqeedo’s current battery offering, the 26-104, is a nominal 24-volt, 104-amp-hour capacity unit. It also offers a 350-watt charger that they say will recharge the battery in eight hours. Like the Mastervolt battery, this battery pack has a very sophisticated, integrated control system that monitors and maintains each cell that makes up the pack. Additionally, the Torqeedo battery pack provides internal over-current and short-circuit cut-off protection. Mastervolt, by comparison, relies on externally mounted protection. Both are fine.

For now, the most suitable application for the battery would be to provide support for their higher-output electric motors such as their “Cruise R” package. This particular motor is the rough equivalent of a 9.9-horsepower outboard engine, but will consume a fair amount of electrical power in service. The Cruise 4.0 for example requires 48 volts to run. So series-connecting a pair of 26-104 battery packs would get you there.

What’s the price of all this green power you ask? Well, get ready to shell out lots of green. Once you get past the price of the motor, you’ll be spending $2,500 each for the 26-104 batteries and another $600 to get the matched charger. That’s $5,600 just for the battery system, more than you might pay for a boat that would run on it.

Bottom line: Torqeedo is the player in lithium-powered, small boat electric propulsion. As such, it can command a high price for its products. Anyone pondering an electric dinghy or day-sailor should check out Practical Sailor’s recent review of the Torqeedo T-1003 (January 2011).

Valence Energy Systems

Valence Advanced Energy Systems seems to have the more diverse lithium-ion product line at this writing, probably because the company is attempting to aggressively target any and all emerging markets for lithium battery technology. It has been in what is called the “large format”(as compared to cell-phone batteries) lithium battery business since late 2007. As of February 2010, the company had partnered with group Beneteau in a collaborative effort with ZF Marine and Volkswagen in the development of their diesel electric hybrid drive system, which has great future potential for bringing this sort of technology into the mainstream.

Photos courtesy of Mastervolt

288

The company is now headquartered in Austin, Texas, with a European office in Antrim, Northern Ireland. Its choice of specific lithium chemistry is lithium-iron-magnesium-phosphate, and it has invested millions in independent laboratory testing to determine that this technology is intrinsically safe. The company claims that since 2006, thousands of its systems have been put to use in both mobile and stationary installations.

Valence is the only company in our grouping that offers what can be considered “normally” sized battery packs that can easily be considered as direct replacements for existing lead-acid batteries. It has two models in its line-up, the U24-12XP and U27-12XP, that are case sized based on U.S. standard BCI group numbers 24 and 27, respectively. These are both very commonly used standard automotive battery sizes, and this sizing probably reflects needs created by Valence’s penetration into the emergency vehicle market sector. Some of the company’s other battery sizes target the electric vehicle or stationary back-up power market sectors.

Like both the Mastervolt and Torqeedo battery packs, these units employ integrated cell-balancing technology as well as comprehensive data monitoring capability, but its BMS module is external to the battery and not to be confused with a dedicated battery charger.

The company offers a series of variously sized and rated BMS modules. These modules can attend to monitoring and battery-to-battery balancing needs in systems that use up to 47 battery packs connected in series. So, depending on system needs, Valence can provide for a system that requires from as little as 10-volts DC to as much as 750-volts DC. A module that has the capability of working with up to 10 of the company’s 12-volt batteries connected in series (up to 150-volts DC) retails for $225. The company claims that any modern battery charger calibrated to work with AGM or gel-cell technology will work with its batteries. Their group 24/12-volt battery retails for $2,200 and its group 27 equivalent retails for $2,500. As part of any installation, users are advised that the remote BMS module is recommended for best results.

Bottom line: Valence is the only company reviewed here that offers batteries in standard sizes, a plus for boat owners with battery compartments that are tight or hard to re-configure.

Conclusion

With what Practical Sailor has learned after putting a microscope on this topic, it’s safe to say that lithium-ion battery technology for use in recreational marine applications is in its infancy. But with a mix of well-heeled yacht owners and green energy zealots willing to lay down the cash, we are seeing steady progress and climbing the learning curve in the right direction.

Global forces are really what will dictate how much people will spend to keep the ball rolling. Certainly in the case of hybrid and total electric propulsion, which are without question several of the biggest potential markets for lithium battery technology implementation, world oil prices will drive the acceptance of alternatives to internal combustion engine drive systems for boats.

Europe is leading the way on that front and it stands to reason. Their price-per-liter of either gasoline or diesel fuel far exceeds anything we have seen yet here in the U.S. The obvious question is: “How long that will remain the case?”

Air quality as well as water pollution on inland lakes and the evolving mandates against internal combustion engines—again, already an issue in Europe—will also be a contributing factor and force the move toward more electric power solutions.

Within the automotive sector, we are seeing continued growth in the hybrid sector. With all-electric cars like the Chevy Volt and Nissan Leaf, it is reasonable to expect that others are going to jump full on to this bandwagon. This bodes well for the lithium battery business, and marine applications will be a major part of the trickle down from this.

When all is said and done, a few key questions regarding lithium-ion battery technology in the recreational marine industry market remain unanswered. We still really don’t know what the actual cycle life of this technology will be under real-use conditions. The information today used by the vendors and proponents of the technology are based primarily on laboratory tests under ideal conditions, not living in the bowels of a boat. Until we see the real-world numbers for cost per watt/hour of electricity produced, this is all just speculation.

Finally, and perhaps most importantly, installation standards for these systems need to be established to ensure boater safety. There are none in place at the moment, although it appears that ABYC may be introducing some relevant standards as early as summer 2011. Stay tuned.

In our apples-to-avocados comparison of lithium-ion batteries, each maker has carved a particular niche. While the weight savings is significant with lithium-ion batteries, the price holds back mainstream acceptance.