Foul tank water is completely preventable. Here are some dos and don’ts for a healthy water tank.

Dont place glycol or other winterizing agents in the tank. Install valves as needed to winterize the pipes only; typically a tee and two valves located near the tank drain work fine.

Protect lines with a minimum glycol concentration of 25 percent and a minimum pH of 9 to insure bacteriostatic properties. (See Step-by-Step Winterizing Tips, PS September 2014 online.) Do not use alcohols. If freezing is not a problem in your area or you can be certain no water can collect in low spots, you can simply blow all lines dry with compressed air (a shop vac will not be enough). A tank protected by either method should keep the system well sanitized and require only a simple rinse before re-commissioning.

Empty, clean, and dry the freshwater tank for storage. It is the right time to do it, just as you put dishes away clean for the off-season. If it is clean and dry, nothing can grow.

Protect the tank vent with a screen (minimum 16 mesh).

Run the tap for several minutes before filling the tank. Dockside hoses always grow algae on the inside.

Filter water before loading to prevent a buildup of solids in the tank. Bacteria need food, and sediment prevents effective sanitizing of the tank. (See Water Tank Filters, PS June 2015 online.)

Treatment

If your tank has been contaminated, a little effort can set things straight. With careful monitoring and pre-filtering of dockside water and pre-filtration, this should only be required once annually or less frequently. Inspect the tank interior regularly for evidence of sediment, algae, or slime on the walls.

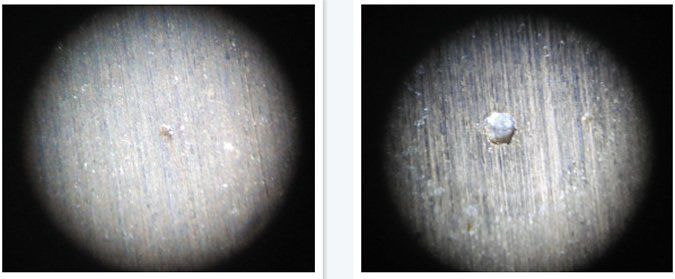

First, the tank needs to be clean. Look inside with a flashlight; is there any sediment on the bottom or scum on the walls? Feel the walls; are they slick, evidence of healthy bacterial growth? It all must go. Hopefully, there is reasonable access, for there is no substitute for a good hand-scrubbing and rinse down with a high-powered hose. Dishwasher detergent works well, as do long-handled brushes. A power washer can help, but some angle fittings will be needed, and it wont do the job by itself. Once youve taken care of any growth, the next step is sanitizing.

The RV code (ANSI A119.2 section 10.8) has a standard sanitizing procedure. Weve added a few details, but the bones of it come straight from the code and have been reviewed and accepted by the U.S. Public Health Service.

Turn off the hot-water heater until finished.

Remove any carbon canisters or micron-rated filters. Remove any faucet aerator screens. Wire-mesh pump protection strainers should stay in place. The plumbing will very likely slough off a layer of bacteria during later flushing steps.

Clean and remove the vent screen and flush the vent hose.

Use either of the following methods to determine the amount of common household bleach needed to sanitize the tank.

Multiply tank capacity (in gallons) by 0.13; the result is the ounces of bleach needed to sanitize the tank. This is 1/8 cup of plain bleach (no fragrance) per 10 gallons.

Multiply tank capacity (in liters) by 1.0; the result is the milliliters of bleach needed to sanitize the tank.

Mix the proper amount of bleach in a 1-gallon container of water. This will provide better mixing and reduce spot corrosion of aluminum tanks.

Pour the bleach-water solution into the tank, and fill the tank with potable water. If possible, allow some solution to escape though the tank vent. (If the vent is exterior, prevent any spillage into local waters.) This will sanitize the vent line.

Open all faucets (hot and cold) allowing the water to run until all air is purged and the distinct odor of chlorine is detected. Leave the pressure pump on.

The standard solution must have four hours of contact time to disinfect completely. Doubling the solution concentration reduces the contact time to one hour.

When the contact time is completed, drain the tank. Refill with potable water and purge the plumbing of all sanitizing solution.Repeat until bleach is no longer detectable.

If the smell of bleach persists after two refill and drain cycles, add a teaspoon of hydrogen peroxide per 20 gallons and mix. The peroxide will oxidize the hypochlorite to chloride (salt) and oxygen, neutralizing the bleach. Any excess peroxide will be harmless to drink and will have no taste. Peroxides are common ingredients in commercially available water fresheners. Dont use vinegar, which can ferment, undoing all of your hard work.

Replace all filters and the vent screen.

Note for aluminum tanks: Corrosion shouldnt be a concern for infrequent cleaning when the recommended dosage and time is observed. As an alternative, we found Puriclean Clean Tabs to be an effective sanitizer, and it was non-corrosive toward aluminum.