A reader recently wrote us that he was shopping for a used boat, and a late model Cabo Rico 38 was among the boats he was considering. He noted that the boat has an internal iron ballast – instead of lead. He was concerned that the boat’s iron ballast (steel actually) was merely a cost-saving measure that brought with it a number of potentially serious problems, especially hidden corrosion.

His query raised another question, and that is, how do you know what ballast material do you have if it is encapsulated? Cabo Rico is one example of a company that produced boats with two types of ballast materials, both encapsulated.

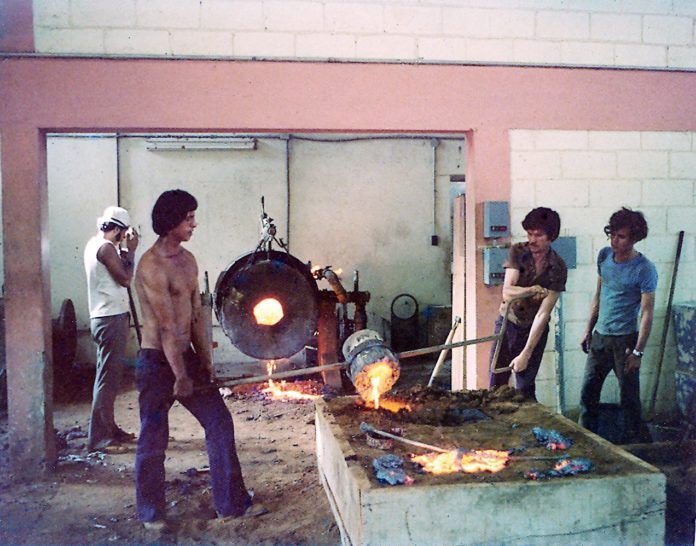

Ben Harrison’s fascinating book “Sailing Down the Mountain,” recounts the early days of Cabo Rico and includes photos of ballast being poured for the early models. According to Harrison, difficulties getting a source of lead ballast led them to a local foundry outside of San Jose, Costa Rica who had a supply of old railroad ties. The steel was then melted down and poured into 11 different molds, which were later encapsulated into the keel.

According the Fraser Smith, the owner/ builder of Cabo Rico since 1987, the company switched from steel to lead ballast castings with the first 38 Pilot model. The change allowed more space for the engine which was moved forward on that model. This change to lead was also included the first Cabo Rico 34 and all Cabo Rica 38 models, years 1989 and later. (Practical Sailor‘s review of the Cabo Rico 38covers some of this history).

However, the key factor with the older (pre-1989) Cabo Rico 38s and the even earlier Tiburon 36 models is that all the ballast, steel (and later the lead), is fully encapsulated in a resin and sand mixture that takes three full days to cure. No air, no rust on the steel ballast. The ballast pieces are wedge shaped so they can’t move.

Then the entire ballast area is covered over with structural fiberglass laminates added to the structural one piece hull. Cabo Rico’s Jim Fraser reports that the company has never had a report of rusting ballast on the earlier yachts. The hull is very thick in that area, hence no real chance of a hole, he says. Fraser says, that in fact, he has have never had a report of a hole in a hull nor lost a rudder a sea-ever. (A challenge, perhaps?)

Darrell Nicholson

Iron keels are either externally bolted on to a keel stub, or fully encapsulated (typically sealed with FRP laminate) within the keel during construction. The same goes for lead keels. Lead is regarded as the better choice, but you shouldn’t disqualify a boat from your search merely because it has an iron keel. If there is iron in the mix, will want to closely inspect the boat for warning signs of larger trouble ahead. Iron, as we all know, rusts quickly and freely when exposed to oxygen and moisture, so it would seem like a less than ideal material for modern sailboat keels. In fact, iron rusts in a more insidious manner than even ordinary steel.

Iron tends to retain its general shape and size as it rusts, however, it decays from within. A piece of iron that appears sound may crumble if tapped with a hammer. This type of decay is called graphtic corrosion, or graphitization because when it occurs, all that remains after the rusting is complete is graphite residue.

Indeed, iron is less expensive than lead, and it weighs considerably less than lead for a given volume (iron weighs approximately 450 pounds per cubic foot, compared to lead, which weighs over 700 pounds per cubic foot). Thus, more iron ballast is needed, with the consequent increase in volume and potential wetted surface and drag, to achieve the same ballasting as lead.

In addition to its cost effectiveness, another reason that iron may be used in place of lead is its environmental friendliness. In many regions, such as Europe, lead is classified as a hazardous material (it is here in the U.S. as well; however, the standards appear to be more strict on the other side of the pond), so many European boatbuilders avoid its use for various regulatory and liability reasons in addition to cost issues.

In general, if iron ballast is exceptionally well encapsulated, both inside the vessel and out, and shows no signs of corrosion, then it is probably safe to assume it will remain this way (looking at sister ships in the same class, particularly ones that are older, may provide valuable clues as to the longevity of the installation). That is, until you run hard aground and damage the fiberglass encapsulation, exposing the iron to seawater.

Even if repairs are made quickly, once water enters this cavity, it may be difficult or impossible to remove completely. From the standpoint of both efficiency (its denser) and its corrosion resistance, lead is preferred over iron for ballast.