We’re cruisers not racers. We like sailing efficiently, but we’re more concerned with safety and good handling than squeezing out the last fraction of a knot. Heck, we’ve got a dinghy on davits, placemats under our dishes, and a print library on the shelf. So why worry about perfection below the waterline?

The reason is handling. A boat with poorly trimmed sails and a crudely finished rudder will miss tacks and roll like a drunkard downwind when the waves are up. On the other hand, a rudder that is properly tuned will agilely swing the boat through tacks even in rough weather, and provide secure steering that helps prevents broaching when things get rolly. The difference in maximum available turning force between a smooth, properly fitted rudder and the same rudder with a rough finish and poor fit can be as much as 50% in some circumstances, and those are circumstances when you need it the most. It’s not about speed, it’s about control.

It Must Be Smooth

Smooth is fast. That’s obvious. But it makes an even bigger difference with steering. Like sails, only half of rudder force comes from water deflected by the front side of the blade. The rest results from water being pulled around the backside as attached flow. How well that flow stays attached is related to the shape of the blade, which we can’t easily change, and to the surface finish of the blade, which we can.

Remember the school experiment, where you place a spoon in a stream of water and watched how the water would cling to the backside of the spoon? Now, try the experiment again as a grown-up, but with a different set of materials.

Try this with a piece of wood that is smooth and one that is very rough; the water will cling to the smooth surface at a greater angle than the rough surface. Try piece of smooth fiberglass or gelcoat; the water will cling even better because the surface is smoother. Try a silicone rubber spatula from the kitchen. Strangely, even though the surface is quite smooth, the water doesn’t cling well at all. We’ll come back to that.

Investigators have explored this in a practical way, dragging rudders through the water in long test tanks (US Navy) and behind powerboats.

If we are trying to climb to windward, it’s nice to get as much lift out of the rudder as practical, before drag becomes too great or before it begins to stall with normal steering adjustments. If the boat has an efficient keel and the leeway angle is only a few degrees, the rudder can beneficially operate at a 4-6 degree angle. The total angle of attack for the rudder will be less than 10 degrees, drag will be low, and pointing will benefit from the added lift. If the boat is a higher leeway design—shoal draft keels and cruising catamarans come to mind—then the rudder angle must stay relatively low to avoid the total angle (leeway + rudder angle) of the rudder from exceeding 10 degrees. That said, boats with truly inefficient keels but large rudders (catamarans have two—they both count if it is not a hull-flying design) can sometimes benefit from total angles slightly greater than 10 degrees—they need lift anywhere they can get it.

How can you monitor the rudder angle? If the boat is tiller steered, the tiller will be about 0.6 inches off center for every degree or rudder angle, for every 3 feet of tiller length. In other words, the 36-inch tiller should not be more than about 2 inches off the center line. If the boat is wheel steered, next time the boat is out of the water, measure the rudder angle with the wheel hard over. Count the number of turns of the wheel it takes to move the rudder from centered to rudder hard over, and measure the wheel diameter. Mark the top of the rim of the wheel when the boat is traveling straight, preferably coasting without current and no sails or engine to create leeway.

The rim of the wheel will move (diameter x 3.146 x number of turns)/(degrees rudder angle at hard over) for each degree of rudder angle. Keep this in the range of 2-6 degrees when hard on the wind, as appropriate to your boat. It will typically be on the order of 4-10 inches at the steering wheel rim. A ring of tape at 6 degrees can help.

How do we minimize rudder angle while maintaining a straight course? Trimming the jib in little tighter or letting the mainsheet or traveler out a little will reduce pressure on the rudder and reduce the angle. Some boats actually sail to weather faster and higher, and with better rudder angles, by lowering the traveler a few inches below the center line.

On the other hand, tightening the mainsheet and bringing the traveler up, even slightly above the center line on some boats, will increase the pressure and lift.

Much depends on the course, the sails set, the rig, the position of the keel, the wind, and the sea state. Ultimately, some combination of small adjustments should bring the rudder angle into the appropriate range. Too much rudder angle and you are just fighting yourself.

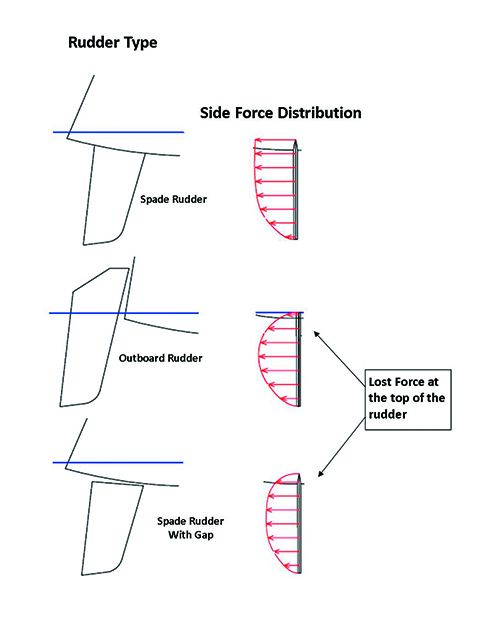

- Turn this rudder just 10 degrees and the end plate is lost, reducing the amount of lift generated.

- This rudder might as well be transom hung, the way that the end cap just disappears.

- Stern-hung rudders, and spade rudders with large gaps between the hull and the top of the rudder will lose their lift at the “tip” of the blade near the surface.

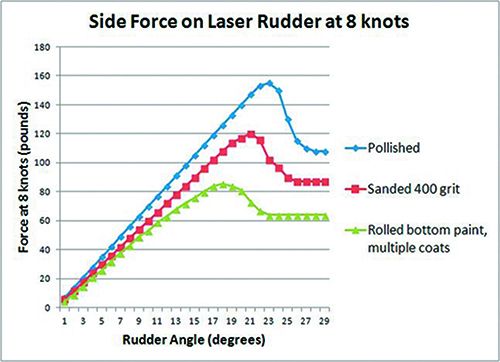

Surface roughness affects the lift from the rudder in two ways. A rougher surface has slightly lower lift through the entire range of angles, the result of a turbulent boundary layer instead of smooth flow over the entire surface. More dramatically, rougher blades stall at lower angles and stall more completely. The difference between a faired rudder with a polished finish and a rudder carrying a 10-year accumulation of rolled-on antifouling paint can be as much is 35 percent (see “Rudder Savvy to Boost Boat Performance,” above).

What can we do? If your rudder is a lift up type, don’t use bottom paint. Fair the blade within an inch of its life and lay on a gloss topside paint as smoothly as possible, sanding between coats. If you use a brush, stroke the brush parallel to the waterline, not along the length of the blade.

Which is faster, a gloss finish or one that has been dulled with 1000 grit sandpaper? Opinions go both ways, and we believe it may depend on the exact nature of the paint, which leads to the question, “Should we wax the blade?” The answer is a resounding, no.

Wax is a hydrophobic (readily beads water), like the silicone rubber spatula you tested, and as a result, water doesn’t always cling as well. Thus, whether the paint should be deglossed or not depends on the chemistry of the paint, but in all cases the final sanding should be 1000 grit or finer.

If the rudder stays in the water, antifouling paint is required. Sand the prior coat perfectly smooth. There should be no evidence of chips, runners, or any irregularity at all. Using a mohair roller, lay the paint on thin, and apply multiple coats to withstand the scrubbing you will give your rudder from time to time.

Even if you use soft paint on the rest of the boat, consider hard paint for the rudder. Sure, it will build up and you will have to sand it off periodically, but the rudder is small and no part of your boat is more critical to good handling. Take the time to maintain it as a perfect airfoil.

Close the Gap

Ever notice the little winglets on the tips of certain airplanes? As we know, those are intended to reduce losses off the tip of the wing. The alternatives are slightly longer wings or slightly lower efficiency. At the fuselage end of the wing, of course, there is no such loss because the fuselage serves as an end plate. The same is true with your rudder.

There’s not much you can do about losses from the tip; making the rudder longer will increase the chance of grounding and increase stress on the rudder, rudder shaft, and bearings. Designers have experimented with winglets, but they the catch weeds and the up-and-down motion of the transom makes them inefficient. However, we can improve the end plate effect of the hull by minimizing the gap between the hull and the rudder.

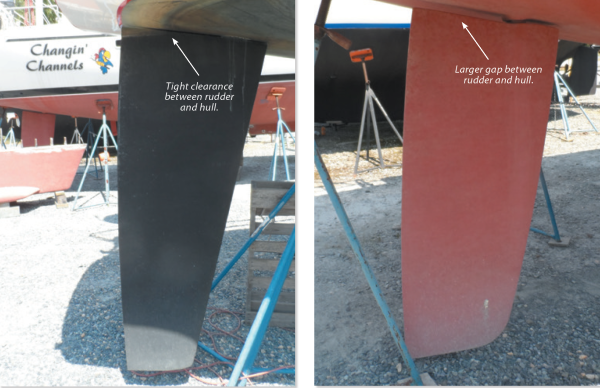

In principle it should be a close fit, but in practice the gap is most often wide enough to catch a rope. Just how much efficiency is lost by gap of a few inches? The answer is quite a lot. A gap of just an inch can reduce lift by as much as 10-20 percent, depending on the size and shape of the rudder and the speed. A gap of 1-2 mm is quite efficient, but normal flexing of the rudder shaft may lead to rubbing.

If the gap is tight, the slightest bend from impact with a submerged log can cause jamming and loss of steering, though in my experience once the impact is sufficient to bend the shaft, a small difference in clearance is unlikely to make much difference; the shaft will bend until the rudder strikes the hull. Just how tight is practical depends on the type of construction, fitting accuracy, and how conservative the designer was in their engineering.

Carbon shafts, tubular shafts, and rudders with skegs flex less, while solid shafts generally flex more, all things being equal. Normally a clearance of about 1/4-inch per foot of rudder cord is practical, and performance-oriented boats often aim for much less. If you can reach your fingers through, that’s way too much. Hopefully the hull is relatively flat above the rudder so that the gap does not increase too much with rudder angle.

Practical Sailor’s technical editor Drew Frye is the author of the books Keeping

a Cruising Book for Peanuts and Rigging Modern Anchors. He blogs at his website, sail delmarva.blogspot.com.

How happy to see good technical information about the science of boat speed and control. This information is valuable to everyone, but the “mainly just cruising” cohort usually doesn’t get enough in an easily understandable form.

I always suggest some club level racing as the best way to learning how to sail, but many prospective racers have been put off from the sport or haven’t had good opportunities to join the fleets. Technical seminars are generally either too advanced for beginners to understand properly, and the beginner classes are frequently too basic to inspre those who would benefit from a deeper knowledge base in the science of sailing.

Good on you, Practical Sailor, for your technical stories hitting the “sweet spot,” getting this information to those we’ll benefit most.

Great article. How about considering modifying a rudder to make it a hydrodynamically balanced rudder. I did it to my boat and the difference is outstanding. If I remember correctly 7% of the rudder area is forward of pivot center. It is a skeg hung rudder that now turns like it’s a spade rudder.

I’m “skeg hung” also. Would you be so kind as to posting a link or providing info as to you accomplished this feat. Thanks!

A very clear explanation of some quite complicated hydrodynamics – thank you! I am surprised by the US Navy results showing benefit of sanding further than 400 grit. Most other experimental data suggest there is negligible advantage in going beyond about 360 grit. Is the original reference publicly available?

On Michael Cotton’s comment, a couple of points:

Firstly, the amount of balance (i.e how far back you put the stock in the blade) has no impact on the hydrodynamic performance of a spade rudder. What it does do is change the feel of the rudder; a well balanced rudder will be easier to use, thereby probably allowing the steerer to sail the boat better. For a skeg rudder, the hydrodynamic impact of changing the balance depends very much on how the skeg/blade combination is configured.

Secondly, 7% of rudder area forward of the stock is not enough for most rudders. The position of the centre of pressure is dependent on a lot of factors (aspect ratio, rudder angle etc.), but it is usually at least 15% back from the leading edge on a spade rudder, more often 20%. A balance somewhere between 10% and 15% is likely to give just enough feel without too much weight. However, rudder balance is still a bit of a black art, it really does depend on the rudder geometry.

the statement that one doesn’t want a silicone/silane coated ( super-smooth, hydrophobic:

silicone-silane is just the example I am choosing, since it is now in use as a massively-speeding hull-coating, ttbomk ), as it *induces* flow-separation…

looks to me like conflating cavitation with flow-separation.

People have no problem teflon/ptfe-coating aviation-wings, as a means of *preventing* flow-separation.

the super-slick shape of a Cirrus’s composite wing, if made super-smooth/polished & super-slippery, “air-phobic”, as it were, *improves* its performance, not detracts from it….

Flow is always

1. laminar, then

2. turbulent, then

3. flow-separation.

unless the angle-of-attack ( AoA ) is small-enough to prevent separation.

The Gentry Tufts System, for *seeing* when a separation-bubble begins, on a sail, is brilliant

( Arvel Gentry was a fluid dynamicist,

& realized that once one has a *series* of tufts,

from luff on back, about 1/4 up the luff,

one can *see* the beginning of a flow-separation-bubble,

& tune the sail to keep it *just*-beginning,

because *that* is MAX lift.

Wayback Machine has his site archived, btw )

The aircraft designer Jan Roskam wrote of a DC-10 crashing because pebbled-ice as thick as the grit on 40-grit sandpaper had formed on the upper wings…

obviously, engineered to require laminar, there, but having turbulent, cost all those lives.

iirc, it was Arvel Gentry, or “Principles of Yacht Design”, that stated it takes a ridge of about 0.1mm, only, to trip the flow around a mast from laminar to turbulent…

Given how barnacles & such are generally 100x or more as thick as that, when removed from a hull, I think laminar-flow is something that exists only for the 1st day or so after launching!

I now want to see experiment showing polar curves for rudders coated normally, uncoated, & ailicone-silane coated, to see if it is the coating that induces separation-bubbles, or if it is AoA exceeding functional angle, for that surface & foil,, while the boundary-layer is in specifically turbulent flow, as opposed to the ideal laminar, as aviation’s results indicate…

just an amateur student of naval-architecture & aircraft-design ( Daniel P. Raymer’s “Conceptual Aircraft Design” is *brilliant*, btw ), who happens to study this stuff autistically, as that is the only way to make my designs become absolutely-competent, is all…

I got a pearson and the rudder broke.

Can I just replace with a outboard rudder mount it off set for room for outboard need info.

You could but it will not work very well. How badly it would perform is difficult to say. It might be just poor or disastrous.

Things really need to be balanced on sail boats.

Polished rudders stall at low angles of attack and ask any hobie cat racer.

Pi is NOT 3.146

3.1416 maybe

Yup, 3.1416. Typo.

Before 2005 , when I fully retired and went cruising 10 months per year, I changed auto pilots, the hydraulics of which reduced the maximum rudder angle. “Someday” had always been difficult to steer in marinas, so I added 30% more rudder area to the Gulfstar 41′ by deepening and following the existing angles. (the pivot was unchanged, as all added area was aft of that.) It increased rudder effort noticeably, but not excessively, improved motor maneauvering and allowed being able to hold a close line better. Noticeably, it caused a lot more stalling of the rudder whenever it was turned very much.

A recent tangle with a Guatemala fish net damaged the extension, which I had intended to be sacrificial. I cleaned up the separation somewhat, but have not replaced the extension. The boat again now requires more steering correction when heading at all upwind, but the rudder does not stall as easily.

This is not a scientific study, just my personal non-scientific observations. The added rudder area was quite low, and the fairing quality was…well! modest.

I’ve seen data suggesting ~ 400 grit is best, and I’ve seen data suggesting polished is best. They were both smart, respected guys that I would not second guess. My conclusion is that other factors, such as the specific foil profile and the type of coating, are involved. Let’s just agree that many layers of rolled bottom paint with a few lumps and chips is sub-optimal! We’re talking about cruising boats.

Thanks for great article. I’m convinced enough to go sand my bottom paint off the lifting rudder of my Dragonfly Tri.

Absolutely! No lifting rudder should have bottom paint. My Farrier rudder was sanded fair and painted with gloss white.

Dagger boards and center boards that retract still need antifouling, since they do not lift clear of the water, but because they are in a confined space with little oxygen or water flow, fouling is very limited. Because the space is tight and paint build-up can cause jamming, sand well and limit the number of coats. For my center board I go with two coats on the leading edge (exposed even when lifted) and one coat on the rest.

I do remember a comment directed to cruisers a few years back suggesting that a faster cruiser would be more likely to get out of the way of dirty weather, especially with modern forecasting. I reckoned that this concept would gain traction, but I haven’t seen it. Can anyone weigh in on this opinion?

I would agree ONLY for coastal crusing when a safe harbor is always no more than a day away. OR ocean racing where speed matters and the boat is kept light. We all know weather reports past 24hours are a guide not a guarantee. Once a storm is bearing down NO boat even a fast one is going it out run a storm. Also we sail on boats that need wind and it’s always a balance between a course between high pressure systems (doldrums) and low pressure systems (high likelyhood of a storm) so because we seek wind sometimes we get more then we want. Try and avoid that and you risk venturing too far into the high pressure system and NO wind. So yes weather forecasts can give you a 1-2 day weather window and a fast boat that can get the hell out of dodge and put a few miles between itself and the oncoming weather could avoid a storm. BUT we are usually not talking about a world ocean race boat vs an old full keel tank. We are talking a faster but still rather slow loaded down cruising boat. It may be only the difference of 7knot average vs 9 knots average. Even a faster cruiser/racer is not a stripped down Volvo series racer. And even those super fast ocean racers pushing the edge of technology get caught in storms and frankly I would not want to use one of those boats as my floating home on the water. They are a thrilling ride but far from comfortable. And they STILL can’t sail fast enough to out run a storm and guarantee you you will never have to sail in big waves and high winds. There is not a cruising SAIL boat that is as fast as a center console fishing boat with 1200hp in outboards on the back and guess what when a squall is coming even they get caught and can’t out run it. And no it’s not a hurricane and it won’t last long but it’s enough when it hits you if your on a light boat over canvased because trying to outrun the oncoming squall it’s enough to get scary. And then there is comfort. Even when there is no storm near you the swell from a storm hundreds of miles away can make for a uncomfortable ride in a boat designed to go fast vs a heavy displacement boat that just pushes threw waves and Has the tonnage not to get knock around. So much of this article screams weekend coastal sailing as even a week on anchor all that work to smooth your rudder will be canceled out by bottom growth todays antifoul paints don’t work as good as the older but far more toxic formulas so even the most meticulously cleaned cruising boat picks up growth ya you can dive and clean it regularly but I often it’s like Sisyphus pushing that rock up the hill. And besides if your sailing on a fullkeel with a keel hung rudder most of this is mute. yes a clean smooth bottom makes a difference on any boat but it’s the full keel and its tendency to track straight the over all weight and momentom of the boat it’s not fast and never will be but they can maintain their hull speed and track a comfortable ride threw chop and be unaffected by the swell. I’ll take a old full keel boat with a protected rudder I know is very unlikely to ever hit something to bend it or loose my rudder ever over a spade rudder or even worse duel rudders both hung exposed with a long but thin bolted on keel that if you hit a coral head means a haul out to inspect it as it more then likely cause a lot of expensive damage. And if not fixed right could lead to a future disaster (Cheeki Rafiki).

As interesting as the article reads, I wonder how it helps a prospective buyer of a used boat. Pictures will not do, and neither will taking several boats out of the water to examine them; it’s too expensive. It would be more helpful to indicate which boat manufacturers have the type of rudder the author recommends. After all, the buyer usually cannot be expected to change a rudder prior to buying it; it is also expensive. By the way, these types of very sophisticated articles are seen when it comes to hulls, keels, or rigging but without identifying the boats that carry the wrong equipment. If a specific rudder or keel configuration is not the proper one for efficient sailing, the author ought to state which boats carry the proper ones so that the buyer will concentrate on the whole (the boat) rather than the part.

I was describing the opportunity to improve the existing rudder. As I think back, I have modified the rudder of every boat I have owned in order to improve efficiency. The first two got small changes in balance and improved trailing edge sharpness. On the third I tightened the the hull clearance and changed the section. On my current boat I adding an anti-ventilation fence to improve high speed handling. https://4.bp.blogspot.com/-2ZGPzKdj_tE/WyF9G2mHtLI/AAAAAAAAOwE/r6zgQEr4vkcDB4ciMLcgboFdazDAseDBgCLcBGAs/s1600/ian%2Brudder%2Bfence.jpg None of these tasks was overly difficult, and none was undertaken until I had sailed the boat for a season and learned what balance she liked and noted her habits.

For me, I buy a boat based on reputation, a test sail, and in most cases, a survey. As you imply, it is the whole boat you are buying. Does it have good bones? Do you feel happy at the helm? Then comes the fine tuning. I’ve been told that I sell a boat when I run out of things to tweak.

wow, so now case reports/medical reports/evidence don’t count as “evidence”, but certain remedies, even if they are cited in medical journals but do not work in the real world, count as evidence to you?? Maybe we need to redefine evidence based on your philosophies.Anyway, i’ve wasted enough time here. goodbye.

Weight 2.5 tonnes

Do you have any articles on the ideal cross section shape for an outboard rudder mounted 50mm from the transom vertically The yacht is a 26 ft trailer sailer weight 2.5 tonnes

The most common choice would be NACA 0012.

http://airfoiltools.com/airfoil/details?airfoil=n0012-il

There are many ways to build a rudder, including laminated solid rot-resistant wood and fiber glass covered foam with a metal armature core. For the DIY, laminated wood is probably the most practical.