The marine environment is demanding, so sacrificing quality is often a mistake. But marine supply stores, and even online “discount” marine retailers can feel like pirates, charging many times more for similar—if not identical—goods found at non-marine sources. So where is worth looking, where is it not? What is a mistake, and which non-marine alternatives may be a smart choice?

Often it depends on the application. Is the component a critical pin high in the standing rigging, or a simple clip securing a bit of fishing tackle? Is it a small part needed during a labor-intensive job, or a sacrificial item, like a fenderboard, that will have to be replaced every few years anyway? Is it exposed to the elements or protected in a dry cabin? I buy from the local chandlery, a well-stocked hardware store, the home improvement center, and on-line bargains, all according to the qualities I need and the best value.

FASTENERS

The marine chandler has a good variety of 316 fasteners for a price, but the local hardware store often beats their selection for metric bolts, pins, circlips, springs, and odd bits. The price and quality are normally similar, often from the same supplier. The home improvement center will beat them both on price, but those 18-8 stainless deck screws and bolts are probably made of lower-grade 304 or 302 stainless (instead of marine-grade 316 stainless steel) and will stain the deck. Also, their long-term strength might not be adequate for a critical job.

However, there is nothing wrong with using an 18-8 bolt or screw in a dry cabin, where salt-water exposure is rare. The cost savings can be substantial For example, the Grade 304 screws required for a piano hinge (sometimes 30 or more) will cost three times less than you’d pay at a marine chandler.

Everbilt, the supplier of Home Depot’s TDX class of fasteners, states that its stainless fasteners are class 18-8, grade 304, and that they use marine grade 316 stainless steel in shackles and some fittings.

Do you need an unusual fastener, such as extra-heavy fender washers for backing hardware, or a very long bolt, or just a lot of something more common? Specialized fastener suppliers like Bolt Depot have a great variety of high-quality hardware for a fraction of the price, but you will need to buy a good handful in many cases.

RETAIL GRADE ALUMINUM FLAT BAR & ANGLE

I wouldn’t use non-anodized aluminum below the waterline or in the bilge, but I’ve built solar panel racks, holders for boat hooks, line hangers, and even a mast hinge brackets from this material, and never experienced any significant corrosion, other than some loss of shine. I’ve also used it for light duty backing plates for cam cleats, etc. With good surface prep it can even be painted.

CHEAP SHACKLES

We’ve tested Everbilt shackles from Home Depot, which we will often use for PS testing projects requiring a lot of pieces, for temporary use, or for non-critical, light-duty situations. PS testing confirms that these shackles are at least five times as strong as the advertised working load, so the maker has assigned them a conservative safety factor. However, they are still only about half the strength of Harken shackles, which cost 2.5 times more. If you need high strength, buy a name brand.

HOSE CLAMPS

Through-hull clamps are critical, so chose carefully. Many hose clamps have a stainless band but use a carbon steel screw, and quality varies. There is always the magnet test; 316 is non-magnetic and 304 is only weakly magnetic, but carbon steel will cling like crazy. Remember, many stainless mechanisms, including very high quality blocks and shackles, often use weakly magnetic ferritic grades of stainless for its greater strength, so weak magnetism isn’t always a disqualifier. See “Stainless Steel Hose Clamps,” PS February 2013.

BRASS FASTENERS AND FITTINGS

Expect great variability in corrosion resistance, because brass alloys are so variable. As a rule use these only for non-critical interior fasteners, and never in the bilge or moisture-prone locations.

WOOD

Marine grades of solid lumber are typically high-grade, without knots, splits, or any defects. Teak and mahogany are extremely rot resistant. But you can get clear, defect-free lumber from lumber yards and even the big box stores, if you are willing to sort through it. Western red cedar is quite rot resistant; look for it in the fence board section. Avoid glued boards unless you can be certain the glue is waterproof.

Inside the cabin, rot resistance may seem less important, but vulnerable woods such as pine are also more prone to mildew stains under the varnish after humidity creeps in. Pressure-treated lumber is too prone to warping and splitting to be of much interest on boats, but fender boards are a perfect example of where pressure-treated wood gives a great combination of rot resistance and economy for what amounts to a sacrificial part that will see rough treatment. I don’t understand the reasoning behind varnished fender boards.

Marine plywood is more complicated. The interior layers of marine-grade plywood are better quality, with no voids. Even good quality exterior plywood will have some internal voids, weakening the sheet and requiring filling of the edges when cut. At a minimum, test the plywood for waterproof glue by cutting a few strips and boiling them in a pot for an hour and examining them for any separation. Were there excessive voids when cut? Failing the boil test is an outright failure even for interior uses; even if sealed, over time it may delaminate or warp. Stick to marine ply for transoms and structural frames, but good quality waterproof glued plywood is OK for less critical backing plates and interior joinery..

PLUMBING (SANITATION)

Marine hose is the best bet for durability and low-odor. Use the white-stuff for vents, since clear PVC kinks and permeates within weeks and the better sanitation hoses don’t come in smaller sizes. Use one of our recommended sanitation hoses for the main runs, doing your best to have them run downhill so they don’t sit full of waste. See “Marine Sanitation Hose Test,” PS April 2012.

PVC pipe is becoming more popular, and for good reasons. It is permeation-proof, as proven by use in millions of homes. It is economical, slippery and clog-resistant, and simple to install. But it is brittle in cold temperatures, so reserve it for locations not subject to impact, foot traffic, or movement underway; use hose were even slight movement is possible. Schedule 40 is much stronger than DWV (drain pipe).

PLUMBING (POTABLE SYSTEMS)

We are not fans of clear PVC tubing. It leaches plasticizers, kinks, becomes brittle, and fails. Nevertheless, we’ve used it in smaller boats and where space is tight; it can work. Look for the “potable” or “NSF-61” designation, and use reinforced type. As for the rest of the options, such as PEX quick-connect tubing, we haven’t found much difference in reliability between “marine” styles by Whale and others vs. residential products. It all comes down to the installer and the design.

PVC APPEARANCE BOARD

Available in boat plain boards and molding strips, PVC appearance board is low strength, but lightweight, rot-proof, and easy to bond with most adhesives (see “Is Azek the New Starboard?” PS December 2021).

VELCRO

Good stuff, but don’t overuse. It does not like UV, it can creep, and it can foul with algae. But it has good uses. Avoid knock-offs; stick with Velcro and 3M brands. Buy the heavy duty stuff. In general, the loop portion goes on the fixed surface (seats, door jams), because the hooks will catch on clothes. The very heavy duty versions, such as 3M Dual Lock, should be used only to fix gear; the grip is so strong it will tear chunks out of netting and knit cloth. The felt-like loop part alone can make a good low-friction slide for windows, companionway boards, and clew straps. The hook part alone can mount pictures and wire hiding strips to fabric hull liners. Velcro One Wrap can be handy for securing cords and keeping furled sails from unfurling when stored.

ELECTRICAL

Good quality is good quality, whether it’s marine or terrestrial. Choosing wire and crimp connectors from name brands is always a good call. Wire does not have to be tinned, though it is the preferred choice for exterior and bilge applications. Inside the cabin, stranded THHN machine wire meets Coast Guard specs and has done well in PS corrosion tests. Never use lamp wire. Never use solid wire. Tinned crimp and terminal strips from Ideal and Gardner Bender are good. We’ve reported on lever-style connectors as a suitable substitute for wire nuts (which are forbidden by ABYC) when used in protected locations. Wago 221/222 and Ideal In-Sure Lever Connectors are good (see the InsidePS blog post “Connecting Very Small Wires on Boats”).

Molded PVC junction boxes and enclosures for conduit can be handy for protecting non-waterproof connectors and terminal strips in damp locations, and in lockers and other locations where physical protection from impact and contact with exposed energized surfaces is required.

Squeeze-on wire connectors do not belong anywhere on the boat. Also avoid Posi-Lock or Posi-Tap connectors.

Be wary of LED replacement bulbs for navigation lights. We’ve seen replacements that caused the fixture to fail to meet the international standards (COLREGS) and U.S. Coast Guard standards for brightness and for beam angle, greatly reducing visibility in certain directions. A slight difference in the geometry of the LED replacement bulb can mean that it is not longer properly aligned with the focusing lens. We’ve also found that some replacement bulbs can create radio interference when located near the VHF antenna.

For additional illumination at anchor or in special situations, we have had good luck with LED tractor-trailer marker lights, which are well sealed, bright, available in several colors, inexpensive, and non-interfering (see “RAM Lights for Sailboats,” PS June 2022).

There are a variety of cord management products good for hiding wires on deck, between solar panels, or in the cabin. They attach with 3M VHB peel-and-stick tape and snap open for access.

PAINT

Marine paint is expensive, but considering the labor put into preparation and careful application, it’s not the place to skimp. On the other hand, Minwax Helmsman varnish has done well in multi-year testing (see “Best Marine Finish; Exterior Wood Finish Tests,” PS September 2011). We’ve used quality exterior enamels, including Rustoleum spray cans, to put a little white on a piece of hardware or some small fabrication we would like to be less conspicuous.

PAINT SUPPLIES

Quality sandpaper, brushes, and tape are all available in hardware store and home improvement centers at lower cost than marine chandlery. But stick to quality natural fiber brushes from recognized makers—Redtree, Wooster, or Corona (our current favorite). Use top-line sandpaper. 3M Cubitron II has tested well (see “Hand Abrasives Round-up,” PS September 2021). Most hardware stores will carry our favorite tapes: 3M green and blue masking tapes (“3M Masking Tape Matchup, PS October 2013).

Painting cones/pyramids may seem like a trivial item, but by allowing you to paint both sides of a flat object in one session, they can cut the time required for many boat projects by 1/2. The concept is simple: Set the object on the top of the “pyramids” which leave only a tiny mark that easily fills in with successive coats (just move the cones after each coat).

Aluminum (not silver-colored vinyl) duct tape is great for sealing opened paint cans. We wrap it around the rim of our expensive anti-fouling paint, so we can use it for our next bottom job. Solvents can go through any plastic tape, but they cannot permeate through metal.

ADHESIVES AND SEALANTS

You can find good deals on adhesive sealants at hardware stores, but stay with respected brands. Locktite PL Marine and PL S40 are good value products. Skip hardware store silicone sealants. The only silicones we recommend are Dow 795 for glazing, and 3M Marine Silicone and Boatlife Silicone Rubber for general use (though mostly, we only recommend silicone for glazing and sealing/protecting wires from chafe where they pass through bulkheads). Also check the masonry department; Sika concrete repair products are typically high strength polyurethanes with forgiving bonding characteristics and superior UV resistance but lower viscosity, which may be handy on some projects. For underwater bedding, use only designated marine grade products—Sikaflex 291 and 3M 5200 are our mainstay products. (Note: PS is currently testing a new round of sealants, but they need another year on the racks before we will report.)

ROPE

Plenty of activities outside of sailing demand good rope, but we’ve found that quality never comes cheap. We like climbing ropes and arborist rope for specific things, but it is either more expensive or about the same, and not woven for the same purpose. We recommend staying with marine rope, but by all means check multiple suppliers.

That said, the cheapest home improvement center rope can be just the thing for testing a rigging modification before you invest real money in 50 feet of the dollars-per-foot stuff it actually requires. You can use this rope to adjust the blocks and leads until everything runs just right, and then take the marked pieces to the store to measure. The junk rope is then coiled away in the garage until next time.

Hardware store bungees were all disappointing in PS testing (see “Shock Cord Test Looks at Long Life,” PS March 2022. Buy bungee from quality rope suppliers or sail maker supply houses.

RV EQUIPMENT

Some gear for recreational vehicles can be interchangeable , but be wary of exceptions. Installation requirements are frequently more strict in boats.

• HVAC ductwork. Hardware and RV stores offer a lot more options that are mostly cheaper.

• Shore power cables. Don’t opt for recreational vehicle or standard grade, they are built to a different code than marine grade (see “Ensuring Safe Shorepower,” PS December 2022).

• Hatches. Use only dedicated marine hatches. We had some garden-variety RV hatches on an old Stiletto 27, but they were built to a far lower level of sturdiness. I guess RVs don’t play submarine in waves.

• Holding tank treatments. In fact some of the best holding tank treatments (Camco STS Ultra II and Odorlos) are RV products (See “Stopping Holding Tank Odors, Pt. II). RV toilets themselves, however will not work on boats, since they are often gravity drop after flushing, not pumped up to a tank.

FABRICS

For exterior use, stick with marine fabrics. We’ve yet to fine cheaper fabrics that offer the value of Sunbrella, Top Gun, or Stamoid (see “Functional Fabrics,” PS December 2011). It’s like rope.

INDOOR-OUTDOOR CARPET

We’ve used runners for a variety of projects. Get the stuff with a rubber back, cut with a hot knife to seal the edges, and you have a new look in minutes. The rubber backing only lasts so long, but by the time it fails, there will be some wear, a few stains, and you’ll be ready for a new look. Not for use in the cockpit, unless it’s a pontoon boat and you like that look!

INDUSTRIAL HARDWARE STORES

Plant operators need stuff and there are industrial suppliers that stock a startling variety of stuff that you probably didn’t even know existed. McMaster-Carr, Grainger, and Bolt Depot are examples. Most big cities have a major supplier of fiberglass, resin, and the tools to apply them. Because these outlets supply industries that are picky about quality control (and often have to meet strict standards), part of the supply house’s job is screening for quality while maintaining reasonable prices. Amazon may have it for less, but quality is a crap shoot.

LUBRICANTS

Two-stroke oil for outboards and air-cooled engines are not interchangeable. Outboard oils contain additional corrosion additives, and air-cooled engine oils are formulated for higher temperatures, contain different additives, and can foul piston-ring grooves on water-cooled engines. Use only TC-W3 rated outboard oils.

The 4-stroke gasoline and diesel oil decision is less clear. There is an FC-W “marine” standard for 4-stroke gasoline oils, which includes corrosion tests not required of automotive oils. The few automotive oils we tested for corrosion resistance did just as well as oils rated as FC-W, and manufacturers told us their automotive oils meet marine requirements.

According to those we spoke with, the bigger automotive brands sell lubricants to outboard motor manufactures to re-label, because the marine market simply isn’t big enough to pursue under their own label. If you have a favorite brand, go with it, remembering to change it annually because salt contamination and moisture are a problem on boats. Also, if you never operate your boat in cold weather, a straight weight (30W, 40W, etc.) may be a better choice, and this is often reflected in service specs. Warrantee requirements commonly require FC-W.

ENGINE PARTS

There can be a lot of overlap in marine and automotive/truck engine parts, particularly with diesels that are marinized tractor motors. But beware that fuel and electrical system components are often very different, meeting different code because of fire and spark hazards. Fuel hose must be marine, for compliance, for insurance, and for safety. We’ve seen non-marine hose fail many times and cause fires a few times. Never a non-marine electrical component or carburetor on a gasoline engine.

CLOTHING

Proper foul weather gear is best for heavy weather or pouring rain. But most day-sailors avoid bad weather and even active sailing on rainy and storm days on my cruising cat required nothing more than a few brief stints on deck to reef or anchor. At the helm, and coming and going from the salon, a comfortable enclosure kept us dry. Lightweight rain gear is more than enough. And wearing off-shore gear around town and to the grocery store seems a little like bringing Attila the Hun to a church social. Buy quality, but not offshore unless you often sail in the rain or are heading off-shore. The accessories, including gloves, waterproof socks, and ski goggles, can be as important as the rain gear.

Sailing dry suits and kayak dry suits have different features and reinforcements, with little difference in price. The marine versions are more convenient.

TOILET PAPER

You won’t go wrong at the chandlery or RV center, but it’s easier just to pick up a fluffy single-ply while you’re at the grocery store (see “Quick Dissolve Toilet Paper Test,” PS June 2011).

CONCLUSIONS

Depending on the scope of your project, you can save hundreds, possibly thousands of dollars by avoiding the marine store chains. In many cases, you can find the identical product for less. Sometimes this can require a little sleuth work, as the two products may have different names, but other times it’s just volume that allows your local hardware store to charge less than your local chandlery.

Also consider product support. This is one reason why we advise sailors to buy marine paints from longstanding suppliers who offer product support—whether it’s your local marine paint retailer, or a regional supplier like Jamestown Distributors. These companies are intimately aware of the challenges their customers face, offer hard-won advice, and are more likely to back their product when something goes wrong.

On the other hand, a 316-grade stainless steel bolt in your local hardware store is very likely sourced from the same supplier (if not a higher quality one) than your local marine chandler. There’s good stuff everywhere. You just need to identify higher-quality grades and recognize when marine is truly different.

Fiberglass shower surround material is one of those home building supply store items that have turned out to be surprisingly useful on our boat for a variety of projects. It’s relatively inexpensive, and a good material for practicing basic fiberglass repair and construction skills.

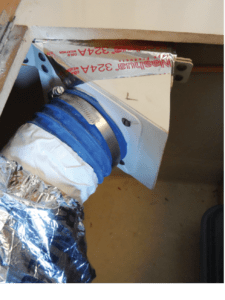

This readily-available thin fiberglass is not very strong and unsuitable for backing plates or anything that sustains high loads, but we’ve found it handy for fabricating small boxes, locker dividers, hanging-locker bag rings, window covers, and air conditioning ducts.

1. A custom vent-box made out of cutoffs from a shower surround panel helps to channel air to the main cabin on our test catamaran.

2. High-current solenoids (shown here) and AC circuit boxes are often sold without the protective covers required to protect them and prevent shorts.

3. In just a few hours, excluding time for epoxy to cure and for paint to dry, we built a protective cover for the solenoid out of shower surround.

UIAA (International Climbing and Moutaineering Federation) rated gear passes as many quality control checks as any marine product, generally more, but it’s built for a different purpose, so you need to pick and chose.

• Rapel rings. “Rap rings” can serve as low friction rings, or as we refer to them: solid, low friction rings (see “Ringing Endorsement,” PS November 2022). We’ve been field testing these for several years with zero problems.

• Sewn slings. These Dyneema webbing slings cost only around $6-$12. They are tested to 4,500 pounds and can serve a variety of uses, ranging from Prusik hitches for mast climbing, to attaching snubbers to anchor rode, to making jury rigs.

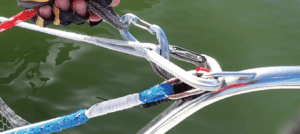

• Wire gate carabiners. Don’t use the solid gate style, which are prone to corrosion problems in the hinge and inside the gate. Locking carabiners also have corrosion problems, unless you commit to a regular maintenance program. But the simple wire gate carabiners are several times lighter than clunky stainless steel marine versions, stronger in similar sizes, and have a much smoother and snag-free action clipping and unclipping. Although they may not last as long as an all-stainless carabiner, they are far more pleasant to use, light enough not to ding the gelcoat, and several times cheaper.

Bolt hangers can be installed anywhere there is an existing 3/8” bolt. The Kong locking carabiners found on many safety tethers are adapted from climbing gear.

• Bolt hangers. Made of 316 stainless, these can provide a strong attachment point anywhere a 5/16- to 3/8-inch bolt exists. If this will be used as deck hardware, be sure to seal any deck penetrations, and use an appropriate backing plate (see PS June 2022, “Bulletproof Deck Hardware”).

I cannot disagree more with some of the recommendations in this article! As a delivery captain who has a strong background in industrial safety, going cheap on safety gear is NEVER a good idea!

ISO 12041 is the standard that most offshore racing bodies require equipment to meet. Anything less has no place on a boat!

This article recommends using single action carabiners and carabiners that lock using a screw-to close system. These devices do not belong on a boat. They do not comply with ISO 12041, and are not approved by ANY offshore racing organization. They have resulted in injuries.

Carabiners that require the user to spin a locking nut to open/close them are unsafe. Going forward on a 45’ catamaran, I clip in at the helm, and then at the next hard point reclip to the other side of the hard point. Heading to the bow, takes 2 or 3 reclip-ins. When things are going sideways, who is going to properly spin close and open the locking nut!

Kong and the newer Spinlock carabiners are double-action, and easy to operate with one hand in the dark. I have logged thousands of miles with these devices. As a professional, I tend to wearout tethers. But I will gladly spend $150 every 2-3 years to keep safe.

Part of the standard crew contract anyone on a boat I deliver must sign, requires them to have a PFD with harness and a double legged tether. If a potential crewman said their carabiner was single action carabiner or screw to close, I would refuse to engage the person until their gear was upgraded.

For those who are not professional mariners, the question is simple. Is your safety worth a few dollars more?

Capt. Bill Herrmann:

I should clarify the context and add a few caveats. An article is often cut for length, with details and precautions occasionally trimmed down. This should clarify.

PS has been extremely active in testing and reporting deficiencies in safety tether carabiners (for example, see “Safety Tether Clip-In Caution,” March 2018) and been instrumental in advancing standards and moving some inferior products out of the market. We agree 100% that safety tether requirements are exacting. In fact, we believe the ISO 12041 standard is deficient in side-loading requirements and support the UIAA 121 standard for type K connector side load test as an additional requirement, which in fact is the standard all current commercial safety tethers are built to (Kong Tango, Wichard Race etc.). OSHA carabiners also have an ANSI side-load test requirement, which the ISO 12041 standard lacks.

(Note that the newer Spinlock carabiners are Kong Tango carabiners. When they retired the Spinlock Race due to deficiencies, the excellent and well-proven Kong was adopted.)

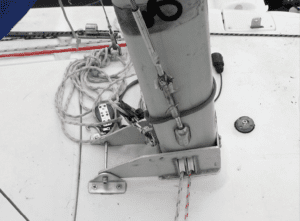

The first two carabiners illustrated (image 1) in the article are serving non-critical, non-life and safety functions. The one in my hand is securing reacher sheets to the pulpit after the sail was stowed below decks. The other was holding a mooring bridle in a retracted position when not in use. Both functions are primarily convenience and the failure of either would result in nothing more than a non-critical rope dragging in the water. These are not applications where a ISO 12041 carabiner would ever be used, the likely alternative being a non-safety rated stainless carabiner, which is heavier, less ergonomic, slower, weaker, and more expensive. The wire gate UIAA 121 carabiner is the best choice, having used them in this and related uses for 30 years. But never for safety tethers or to as main support or backup when climbing a mast. No climber would do that.

The adjacent (image 2) shows A Wichard Proline carabiner (which meets both ISO 12041 and UIAA 121 type K) securing a safety tether. It is a design adapted from climbing gear, as the caption says. The Kong Tango, used by many manufacturers including Spinlock, is another popular design for safety tether connections. We will all agree that the Kong Tango and Wichard Proline are suitable for this purpose, these are the ones we use, and we like them. We will add that operability with insulated gloves is another requirement.

Screw lock carabiners are appropriate in mast climbing applications. For some safety equipment rigging they are the only appropriate connector, they are the connector that the gear was designed for, and ISO rated using. However, for the reasons stated (can’t work with one hand) they are not appropriate for deck safety tethers. Climbing is a different purpose, but it is a purpose on a boat, and they are often the best and safest tool for the job.

We apologize for any confusion. We should have clearly stated that the wire gate carabiners, whether rated for climbing or not, are not to be used for safety tethers or for support when climbing the mast.

Drew

Thank you for that clarification. Yes I know from experience that the editor can be ruthless. Hopefully there will be a clarification in next month’s issue.

Bill

Climbers do use non-locking carabiners, but never as a sole means of support. They are used for running belays, which have no parallel application in sailing. They are for a different type of climbing, and I see how that could be confusing.

One application where I like more strength and security, but do not want a locking carabiner (of any kind) exposed to long soaking in seawater, is attaching a snubber or bridle to the rode using a prusik hitch. One solution, which increases security to very near that of a locking carabiner, is to use two wire gate carabiners, with the gates reversed and opposed (one opens up, one opens down, and then flip one over). In fact, this is what is illustrated in the article (image one); one bridle line goes to each bow, and they are connected to the rode using a prusik hitch and two biners. I pull the bridle back to the pulpit, because climbing out on the skinny bows of a trimaran, with no lifelines, is a little scary, even in harbor.

I’ve never heard of this coming open and it was often used before locking carabiners became common. Also a contingency method for when you are up a big wall and drop your locking carabiner! But not for mast climbing or tethers.