Controlling Motion: Two Case Studies

Securing a small boat between pilings in a wrong-sized slip is a common challenge. The dock line angles from the dolphins (outlying pilings) are...

Improve Your Catalina 30: Upgrading the World’s Most Popular 30-Footer

The Catalina 30 is a remarkable success story. We suspect that more Catalina 30s have been built than any other boat of that size...

Backyard Boatbuilding: A Father-Son Odyssey

Boatbuilding is a test of Archimedes Principle of buoyancy, but it also harnesses mans impulse to turn dreams into reality. For the father-and-son team...

Making Engine Oil Changes Easier

Some boat manufacturers have no concern for simplifying things, like changing the auxiliary engines oil, once the boat leaves the factory. But the process...

A Permanent Mount for the Sensibulb LED Reading Light

A Permanent Mount for the Sensibulb LED Reading LightBy Thomas WetherbeeI have always been a big fan of brass berth lights, but have never...

3M Masking Tape Matchup

Most sailors have discovered that when it comes to applying marine coatings, masking tape is as important as a paintbrush if you want straight...

Paste Waxes Test Six-month Checkup

How long do they last? In the February 2009 issue of Practical Sailor, we reviewed a sampling of 10 paste waxes that were available...

Mailport: Marelon Seacocks

Regarding your recent report on Seacocks (Beneteau Responds to Seacock Query, PS August 2018) I owned a 1987 Catalina 30, Mark II. It had...

Design For: A Dock Box

Whether by choice or force of circumstance, increasing numbers of us are sailing out of marina slips rather than off moorings. For anyone using...

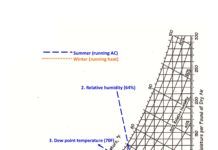

How to Measure Boat Humidity: Psychrometric Charts Do It Right

Insulation is a greater energy-saving expedient; if our heater or air conditioner is undersized, fixing drafts, shading or insulating windows, and insulating non-cored laminate...