What’s the Best Anode Material?

Every fall, as the hauled-out boats are sardined into boatyards, a walking tour reveals the casualties from the underwater war. Saildrives are deeply pitted...

Are Mildew Preventers the Best Defense?

In January 2009, Practical Sailor tested 14 mold and mildew cleaners, and two household products stood out: the super-chlorinated Klean-Strip Mildew Stain Remover and...

Mast Support for Trailerable Boats

The transom support is a simple design. It is merely a 1" x 8 " board of a convenient length fastened to the rudder...

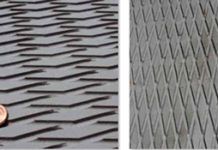

Nonskid Test Update

Practical Sailor recently tested a nonskid mat from Soft Deck Inc. as a followup to our January 2012 report on do-it-yourself options for replacing...

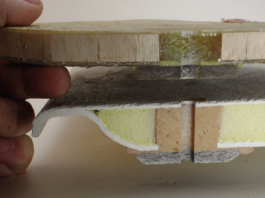

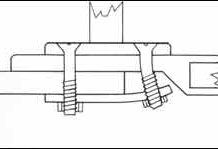

A Better Way to Mount Hardware

Improperly mounted stanchion and pulpit bases are a major cause of gelcoat cracks in the deck radiating from the attached hardware. The cracks are...

Rating Paint Panels

The paint samples were applied to 6-foot-by-2-foot fiberglass panels for testing. Testers follow the makers’ instructions for preparation and application. There were 11 samples...

Mailport: August 2013

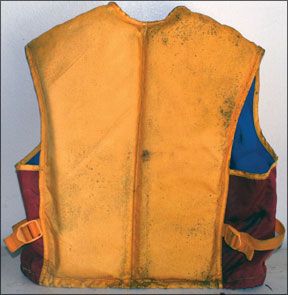

On strolling through Port Townsend (Wash.) Boat Haven, while I was having some work done on my boat, I saw this boat (photo at...

2017 Top Sailing Gear

Scott Rapid Dissolve Toilet PaperFollowing a carefully considered protocol that is not worth delving into here, testers took a second look at toilet paper...

Measure, Cut, Glue and Repeat

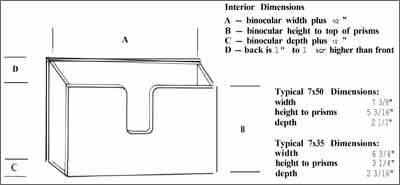

Generally, a deep locker will have a recessed lid. Some modification may be needed to fit locker bags.

Rebuilding a Cape Dory 36

This is Part 1 in a multi-part series detailing the rebuilding of our then 35 year old Cape Dory 36 sailboat. The purpose of...