Design For: Accessible Radio Rack

Radios occupy an important place in the contemporary sailing scene, supplying weather reports, time ticks, entertainment, and news. High quality radios are also expensive....

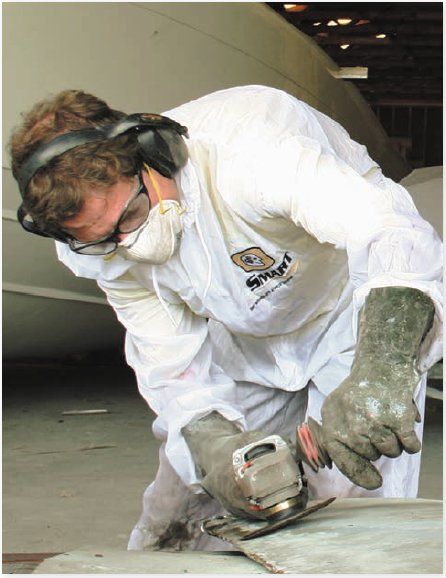

Ralph’s Great Adventures in Laminating

Technical Editor Ralph Naranjo equates spare time with boat projects. His basement shop/test facility has spawned a wide range of boats, boards, and parts...

Descaling Solutions for Boats

In addition to all of that lovely salt, seawater is very hard, nearly saturated with calcium. All it needs is something to react with...

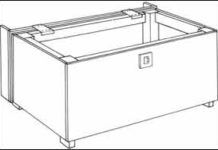

Design For: A Dock Box

Whether by choice or force of circumstance, increasing numbers of us are sailing out of marina slips rather than off moorings. For anyone using...

Even 2020 Yielded Some Great Gear

Once more, the bulk of the past year’s testing focused on maintenance products, safety essentials, and do-it-yourself substitutes for higher priced marine gear. Part...

Sparkling Brightwork: Careful Attention to the Details

It takes practice to produce a perfect, mirror finish on varnished wood, but it is not so much a difficult task as an exacting...

Bottom Paints for Brackish Water at 1 Year

For more than four decades, Practical Sailor has been testing bottom paints, although for the first few years, the topic really didn’t draw much...

Wear and Tear Pad Review

Over time, chafing from lines can actually wear away gelcoat. Likewise, chips will appear where hatches or ports bang. While eliminating chafe is the...

Design For: Tableware Storage

One solution to the problem of tableware stowage is a bulkhead rack of the type commonly available from marine chandleries and discount houses. If...

25 Paints Make it Past the 24-month Mark

In July 2009, 61 samples of antifouling paints, including several new formulas, went into the water in Sarasota, Fla., for testing. This report and...