Paste Waxes Test Six-month Checkup

How long do they last? In the February 2009 issue of Practical Sailor, we reviewed a sampling of 10 paste waxes that were available...

Practical Sailor Launches Long-term Liquid Boat Wax Test

In the February 2009 issue of Practical Sailor, we reviewed paste waxes, those harder compounds normally sold in cans or tubs. In our perennial...

Diesel Biocides Take On Contaminated Boat Fuel

Whenever sailors talk about dirty diesel, advice springs forth regarding the best type of filter, the best stabilizing additive for long-term storage, the best...

Conversion Kits that Turn Your Boat’s Ice Box Into a Galley Refrigerator

During the past few decades, a technical evolution has made the hardware that powers the refrigeration cycle more efficient and more reliable than ever....

Do-It-Yourself Boatyards

The cost of buying, owning, and maintaining a sailboat has spiraled to an all-time high. The ranks of entry-level sailors, starting out in smaller...

Shore-Power Boat Fire Protection

With the increased demand to have all the electrically powered comforts of home onboard, it should come as no surprise to boaters that the...

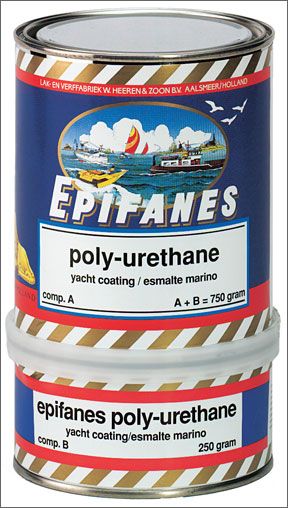

Six-Month Checkup: Long-Term Boat Wood Finish Exposure Test

Do you ever wonder why its called "wood finish?" Youre never "finished" with it. Unfortunately, that rings true for most boat maintenance tasks. With...

Eco-friendly Boat Maintenance

In the May 2008 Practical Sailor, we looked at eco-friendly marine maintenance products for outside the hull-less toxic bottom paints, paint strippers, waterline stain...

Next Best Thing

While world leaders and presumed financial wizards set to work trying to right the global economy with some very expensive bailers and sponges, Practical...

Bottom Paint Tests 2009 Spring Update

Over the years, Practical Sailor has tracked the evolution in marine antifouling paints. Shaped by government regulations, environmental concerns, and industry innovations, the shift...