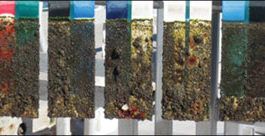

Bottom Paint Test Updates

Sure, grading antifouling paint panels probably doesn't qualify for the television show "Dirty Jobs," but after 20-plus years of counting barnacles, ones mind does...

PS Advisor: Do Alcohol and Antifouling Mix?

Today I went to paint the bottom of my boat with Interlux’s VC-17m, which I have used since it first came on the market....

Bio-Solv Green Acetone

A bottom-paint job is unpleasant from start to finish, and wiping down the hull with acetone plays a role in that unpleasantness. So when...

Mailport: February 2010

I understand you are going to do an article on navigating by phone using the iPhone. I thought you may be interested in my...

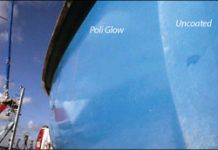

Liquid Wax Test Reaches Six-month Mark

Thankfully, it is not our job to develop a product that satisfies humankind’s seemingly innate attraction to glossy surfaces. There are more than enough...

Exposure Test Results: Varnishes, Teak Oils, and Other Exterior Wood Coatings

Science and technology have turned the once-simple task of choosing a wood coating into a brain-numbing chore best suited for those with a degree...

Topside Paint Exposure Test Checkup

Last year, we launched a multi-phase topside paint evaluation in search of a high-gloss, easy-to-apply, durable coating for fiberglass hulls. We began in the...

Affordable Marine Antifouling Paint

Practical Sailor spends a lot of time studying bottom paint for good reason. Bottom paint prices continue to rise, pushing the $300-per-gallon mark, and...

How Do Acrylic Finishes Hold Up Compared to Boat Waxes?

The search for shortcuts to a shiny hull ends here at Practical Sailor, and while weve yet to find any "miracle" products, new technology...

Practical Sailors Gear of the Year 2009

As each year nears its end, Practical Sailor editors find themselves poring over the dozens of products reviewed in the previous months to choose...