Mailport 08/01/00

Handheld GPSI have the greatest respect for the equipment reviews in Practical Sailor, but I think that you overlooked very critical attributes for your...

Mailport: 04/01/05

Chainplate Adhesion I read with interest your article on chainplates. I hope that readers will not misunderstand the discussion of the failure of...

Mailport 02/01/01

Inflatable PFDsAfter reading the piece on inflatable PFDs (October 1, 2000) I want to tell you about a recent experience on San Francisco Bay.For...

Mailport: 11/06

]In regards to the PS articles Bye Bye Black Blight and Star Brite-Rust Erasers (May 2006): From my experience, Turtle Waxs Chrome Polish and...

Mailport: fuel tanks, chain hooks, bilge pumps, and hypothermia

Fuel Tank Wisdom

Simple tank fill advice from an old fuel oil delivery guy - when filling your boat diesel tank listen to the sound...

Making an Anodized Mast Look Like New

Have you done any research on the best means of cleaning an aluminum mast? Im having other work done to mine and thought it...

Mailport: 04/06

Mud MastersHerewith some comments on your useful experiments concerning anchor holding power in soft mud as described in Anchors for Muck, for Under 200...

Product Update

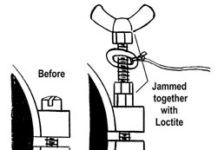

Since our last large-scale field test of wind generators (see PS, July 2007 online), our Budget Buy pick, the KISS high-output wind generator, has...

PS Advisor 05/01/99

CQR AnchorIn your anchor tests in sand (January 1, 1999) you rated a 22-lb. Bruce against a 35-lb. CQR. Why not a 33-lb. Bruce,...

Aqua Signal Recalls Series 40 Bi-color Nav Lights

Aqua Signal Corp. (www.aquasignal.info) recently recalled a small number of its popular Series 40 bi-color navigation lights. The recalled lights, manufactured between November 2010...