Field Testing Treatments

Approximately 150 feet of 7/16-inch rope will fit in a five-gallon bucket. This requires one 500-milliliter bottle (17 ounces) of Rope Proof or 4...

Practical Sailor’s 2011 Gear of the Year Picks

Pressure CookerOur Gear of the Year galley pick is the Kuhn Rikon Duromatic spring-valve pressure cooker. Pressure cookers are the cruiser’s answer to the...

Buyers Guide: Choosing a New Cruising Main

The mainsail of our Chesapeake Bay test boat was intact, but, after exhausting every life-extending option available—including patches, repairs, re-stitching, and tune ups—it became...

What’s the Best Way to Clean Marine Rope?

Every spring, there are numerous threads on the sailing forums discussing the best ways to clean ropes, mostly about dock lines. Brutal methods are...

The Multifarious Mainsheet

The mainsail is a big part of the motive power of almost every sailboat. The art of mainsail control, however, is a relatively modern...

Clear the Decks: Anchor Wells and Bow Rollers

Ever since some ancient mariner broke a toe tripping over the killick stowed in the bow of his curragh, sailors have sought to solve...

Smooth Runnings: Bullet Blocks Battle

ConclusionBackground testing did show that undersizing a block makes the work harder to accomplish and will shorten the lifespan of the equipment used. When...

From the Bench to the Bath

With some modification to our bench-test jig, we were able to place two blocks in opposition to each other, attach them via a closed...

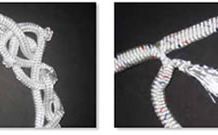

Rope Test Yields Rope Hernias

Researching an upcoming article on the effects of various cleaning chemicals on ropes, our testers scrubbed and machine-washed mountains of nylon and polyester rope...

Sailboat Design Conference Part I

We interviewed five leading designers of recreational and cruising boats to better understand the way they view the market and what considerations reside behind...