AGM Batteries: Optima Our Choice

The basic lead-acid storage cell was invented by Thomas Edison in the late 1800s, and the fundamental chemistry hasn’t changed since. If you suspend...

The Get-Home Sailboat Tool Kit

The tools and materials required to maintain and repair everything on a boat will barely fit in a room. Just the kit required to...

Yet Another Motor Hoist-the Kato

Lifting the outboard motor from the dinghy to its mount on the stern rail (or pushpit as the Brits say) has always been a...

Keep Your Cool With A/C

The demand for marine air-conditioning (A/C) continues to increase. Once found primarily on medium to large boats, systems suitable for even the smallest cabins...

Offshore Log: A Simple Outboard Lifting Crane

For two years, we struggled to get our 8-hp. Yamaha outboard from its storage location on the stern rail to the transom of our...

In Search of Better Filters

Presumably, air cleaners are about dusty environments, and dust is a rare thing on the water. But is the engine room actually clean?

We’ve seen...

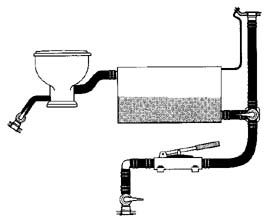

Marine Sanitation:SeaLand Holding Tank Systems

SeaLand Technology of Big Prairie, Ohio is not a diversified company. Once part of Mansfield, the largest maker of home toilets, SeaLand was spun...

Where Credit is Due: July 2011

In regard to the article in the April 2011 issue on a shower solution from Whale Pumps (www.whalepumps.com): I have been looking for a...

Battery Monitors: The E-Meter Vs. the Sophisticated SALT

In the February 15, 1997 issue, we reviewed battery monitors and stated that Cruising Equipments E-Meter was the only one of the four models...

Deck Vents: Nicros Water Trap and Plastimos Cool n Dry are Clever and Effective

Cowls are descendants of simple vent pipes on sailing ships, cousins to the famed Charley Noble over the galley. When ships acquired engines below,...