Elizabeth Barrett Browning would have a fine time counting the variety of ways to treat waste aboard a sailboat. Let us count the ways. Apart from the “standard” electric toilets that we tested here (either raw-water or freshwater plumbed), there are portable toilets, composting toilets like the Air Head, hold-and-treat systems like Raritan’s Lectra San, and vacuum-based systems like Sea-Land’s VacuFlush. In addition, there are multiple ways to plumb a holding tank into the system.

Most of the manufacturers in our test this month offer selection and installation guides on their websites, and products designed for specific installation scenarios. Two good resources for do-it-yourselfers contemplating an upgrade are Nigel Calder’s “Boatowner’s Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat’s Essential Systems,” and Peggie Hall’s “Get Rid of Boat Odors: A Boat Owner’s Guide to Marine Sanitation Systems and Other Sources of Aggravation and Odor.”

Follow the installation instructions carefully as to discharge sanitation hose size and wire gauge (no more than 3-percent voltage drop). These units have high start-up demands, so sizing for the smallest acceptable gauge is not wise. The two most common causes of poor performance are lack of water and insufficient power, both of which can lead to clogging.

Raw-water inlets (on those designed for raw water flush) or outlets plumbed directly to through-hulls should have vented loops to prevent water from siphoning back into the head. However, air in the inlet line can hinder pump performance, so a solenoid may be required to close any vented loops in the raw water inlet line during flushing.

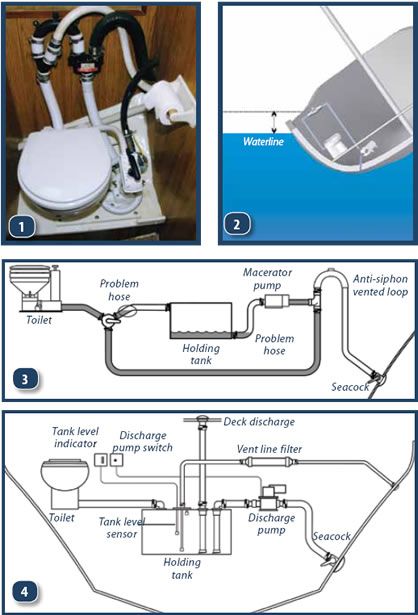

1. Most contemporary manual flush systems incorporate a Y-valve that diverts waste to the holding tank or overboard. While a well-designed system will provide years of service, the DIY result is often a pretzel-like series of poorly clamped hoses such as this.

2. Raw-water inlet and outlet lines need anti-siphon vents. The vent must loop above the waterline at all angles of heel.

3. Early holding tank designs had leak-prone outlets at the bottom of the tank and often lacked a deck-level pumpout fitting. Similar systems, with the addition of a deck pumpout, are common today. Ideally, a system should not trap waste in the lines.

4. At the other end of the design spectrum are systems tailored for areas where pumpout facilities are readily available, like this one from Dometic. Instead of a Y-valve, multiple check valves prevent back-siphon.