Every now and then, we find ourselves returning to tried and true products, curious if there is some overlooked application for sailors. It was in this hopeful spirit that we devised a battery of tests for Shoe Goo, the sticky stuff first introduced in 1972 as a tennis shoe repair glue, but later championed for all sorts of repair jobs—boots, tents, waders, just about anything rubbery that might wear quickly or come apart.

We had high hopes we’d find a range of uses for the original formula on our test boats. We were also curious about a Goop Marine, a similar product from Shoe Goo’s Oregon-based manufacturer, Eclectic Products, so it was also added to the test. Shoe Goo II, a low odor version of the original, was not tested.

The UV resistance of the original formula is too poor to recommend it for continuously exposed use, so that rules out it’s viability as a sealant. But there are a few specific applications where good ol’ Shoe Goo outperforms any other product we’ve come across. Before we share our real world experiences, let’s look at the numbers.

HOW WE TESTED

We bonded samples of aluminum, fiberglass, and polyethylene and tested them for shear strength. We bonded fiberglass samples at a 90-degree angle, and put them on racks in the sun and soaked them in water for months, just like other sealants we have tested (see

“Marine Sealant Adhesion Test,” PS December 2016). We mixed in some manufacturer values and produced a summary of physical properties.

Compared to 3M 5200 (polyurethane adhesive sealant), it is harder (80 vs. 68 Shore A), making it a poor sealant for anything that flexes or moves. However, its high-bond strength to materials other than polyethylene recommend it for certain types of bonding, including rubber and fabrics.

Its abrasion resistance is much better than 5200, recommending it for footwear (that is what it was invented for) and fabric repairs where abrasion resistance is critical, including luggage, packs, and sailing gloves. It’s less appropriate for on-deck deck upholstery and vinyl because of its limited UV resistance.

Shoe Goo dries tack-free on the surface within minutes, making tooling difficult. Unlike polyurethanes, which cure through a reaction initiated by moisture on the bonding surfaces and in the atmosphere, it dries by evaporating solvent (perchloroethylene). This means it shrinks. Single applications should not exceed 1/8-inch, and each layer will shrink about 30 percent upon drying.

Our samples for the shear test, trapped between impermeable sheets that would not allow the passage of solvents, took as long as four weeks to dry completely at 75 F. Shoe repairs, on the other hand, are generally wearable in 24 hours.

Samples submerged in water showed no deterioration. We’ve used them to seal aquariums, but other sealants are generally preferred because of greater flexibility.

Adhesion to fiberglass and aluminum is better than polyurethanes. Manufacturer data suggests the strength is similar to G-Flex. Adhesion to polyethylene was very poor, but this is true of most sealants, and adhesion to other plastics and elastomers is very good, so long as the flexibility is similar (you need a very flexible sealant to bond to very flexible materials).

UV AND OIL RESISTANCE

Based on the results of our panel tests, Shoe Goo can provide a few years of service, but experience tells us it will stiffen and get brittle within five years. The manufacturer recommends painting the glue if UV resistance is required. For repairs that will see a lot of sunlight, your best bet is RTV silicone.

Based on our testing, Shoe Goo does not handle petroleum products well. The same is true of polyurethanes.

Despite these few limitations, we still like Shoe Goo for protection against abrasion and for fabric repairs.

GOOP MARINE

Now, about the other stuff, Goop Marine (aka Amazing Goop Marine), which is also made by Eclectic and aimed at the boating market. Goop Marine fared much better in the sun, and was harder than polyurethane sealants. It is stronger than polyurethane, but stiff. It’s not flexible enough to perform as a sealant, to repair sails, or for canvas repairs that flex a lot.

Goop Marine has a similar chemical consistency as the original Shoe Goo. It also has similar physical properties, but is less viscous, so it is easier to apply, but harder to build up thick layers on a shoe sole.

APPLICATIONS

So what are these Goos and Goops good for?

• Contact Adhesive. If you apply a thin coating of Shoe Goo to two surfaces and let both surfaces dry for 2-3 minutes, they grab like contact cement. You won’t be able to reposition them and you won’t have to clamp them, but light pressure for 15 minutes ensures a good bond. This is a handy characteristic when re-bonding soles.

• Shoe repair. It fixes shoes, of course. It doesn’t improve the grip on deck shoes. It’s not as grippy as the original rubber. But it is very good for gluing soles back on, and for protecting areas around the edges on toes that can wear out during extended periods at the helm. It is excellent for building up the heels on favorite around-town shoes or for protecting the heels of shoes that see a lot of use.

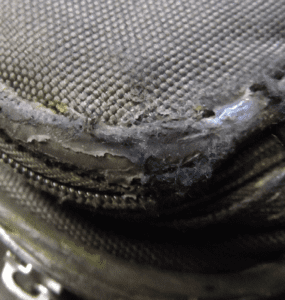

• Protect luggage. We travel a lot and don’t mind luggage with a well-travelled look, but fabric can wear through after bouncing over too many curbs and scraping around conveyer belts in the baggage claim area. When rubbed into chafed areas before complete failure, Shoe Goo stops the wear. We’ve never seen anything like it.

• Chafe prevention. We like Yale Maxijacket for chafe resistance on canvas and ropes, but Shoe Goo is even tougher. Skateboarders use it to reinforce the fabric uppers on their sneakers against abrasion.

• Seal sewn splices. If you want to project sewn splice from abrasion, two coats are best. The first coat should be rubbed in; the second should coat the surface. Goop Marine soaks in better because it is thinner and more UV resistant, so it is the better choice for this use. It is good for protecting whipped lines as well.

• Fix gloves. As when repairing luggage repair, if you work Shoe Goo into the worn areas before they fail completely, those areas will last longer than the rest of the glove, adding grip at the same time. It is also good for edges on the wrist and fingertips. Rub in thin layers. Less is more.

• Mend neoprene. It’s not flexible enough for wet suit repair (use Aquaseal). But it is good for repairing the hard sole of wet suit booties.

• Repair cuts in bike tires. Cut an oversized patch from Sunbrella or similar canvas, put a large spot of Shoe Goo in the center, and apply firmly to the inside of the tire. The Shoe Goo bonds the patch to the tire, and the excess squeezes into the cut, slowing wear. .

• Fix cushions. Shoe Goo repairs tears on cockpit cushions and worn areas of canvas, but Goop Marine is the better choice. Although Goop Marine’s UV resistance is good, plan on replacement within a few years.

CONCLUSION

These Goops won’t replace marine sealants or adhesives for bedding, sealing, and most bonding jobs, but they have some interesting bonding characteristics, especially with fabrics. They will definitely stretch the life of shoes and gloves, and will protect against chafe in a pinch. We consider them to be a good addition to the cruiser’s bag of tricks.

I love discovering new applications for proven compounds. Would Shoe Goo / Goop Marine work for repair of PVC (inflatable paddleboards) or hypalon (inflatable dinghies)? I’ve used G-Flex on these with good results.

Greetings, My 5 year old Dubarry boot soles have left their uppers. Reading this article makes me wonder if shoe goo or 5200 would be a better repair try due to flexibility. Would appreciate your insight.

I have used Shoe Goo on work shoes on which the steel toe was falling out, gooped it up, taped it up with Duct Tape for a day and they lasted me another two years! The gloves is also a good tip, we use Kevlar knit gloves for TIG welding, and have been smearing Shoe Goo on the fingertips for years, and it keeps them from wearing through due to the ARC and abrasion. Only complaint is that a tube doesn’t last that long. Not surprising seeings as you mention it contains perchloroethylene – I will be more careful in using it in the future. My good friend and his wife died from that 40 years ago.