Diesel engines have evolved into incredibly reliable power sources. Change the oil, mind the charging system and batteries, and most importantly, always give them clean fuel.

First there is diesel bug. Bacteria and fungus (not algae-that is incorrect nomenclature) can infect the tank, feeding on the diesel and producing volumes of tank-, line-, and filter-clogging biomass with the consistency of snot. It can be prevented by the regular use of biocides (see PS August 2013), but don’t use biocides to cure an existing infestation; the bugs will die, slough off, and clog everything. If you have diesel bugs, you need to clean the tank, followed by preventative bug treatments in the future. This will also kill the bugs in the pipes that you missed.

Diesel bug can also be prevented by keeping the fuel scrupulously dry. Check the filler cap and replace the O-ring every two years; leaky filler caps are the leading cause of wet fuel. Examine the vent. Can waves get in? Is the loop high enough? Use separating filters, like the Parker Racor series. Sump the bottom of your tank twice a year using an oil suction pump. Silica gel vent filters (see Diesel Tank Vent Filters, PS January 2014) prevent atmospheric moisture from absorbing into the fuel and falling to the bottom.

Another source of solids is asphaltenes. These are polymers formed when unstable diesel fuel ages. With time, the fuel becomes darker, slightly cloudy, and a thin layer of black tar accumulates on the bottom. Most diesel is stable, either as a result of refining practices or additives, and will not do this for many years if stored dry and away from copper and zinc alloys (see page 16, Diesel vs. Copper and Zinc).

Because asphaltene particles are small and soft, even fine filters may not remove them (they can deform and flow through the pores). However, generally they are not damaging to the injection system, again, because they are soft. The extent of the problem varies regionally with the refinery and crude oil source, but with proper storage practices and supplemental stabilizers, quality diesel fuel should be stable for several years. Biodiesel is less stable and more prone to sludge formation.

Diesels don’t have a spark and or fussy carburetors, but injectors and injector pumps are precision machinery that wont tolerate dirt. Newer common rail engines commonly require two-micron filtration.

Gasoline Filtration

Gasoline filtration is generally less problematic, primarily because there is no such thing as gasoline bugs (gasoline is too toxic), but fuel-injected outboards can still have their issues. If you run ethanol-free gasoline, water separators can be helpful. If you are running E10, they are not. If the ethanol-gasoline blend gasoline is unseparated, there is zero free water to remove. The blend dissolves any droplets. If it has separated, then no separator will work.

Separated gasoline has less difference in density than separated diesel (the water phase is actually mostly ethanol), the water phase is not easily rejected by hydrophobic filter media (again, the separated solution is mostly ethanol), and the octane of the gasoline is now too low with the ethanol removed. If the gasoline has separated, the only thing to do is pump out the bad gas in the tank and lines, figure out how the water got in, and start over.

Finally, corrosion products, either from the tank (diesel) or from within the carburetor itself (gasoline) can cause trouble. PS has tested both gasoline (PS August 2012) and diesel additives (PS August 2013) for corrosion protection, and we are working on a gasoline additive update. These reports are very valuable to sailors, since we use our engines less frequently.

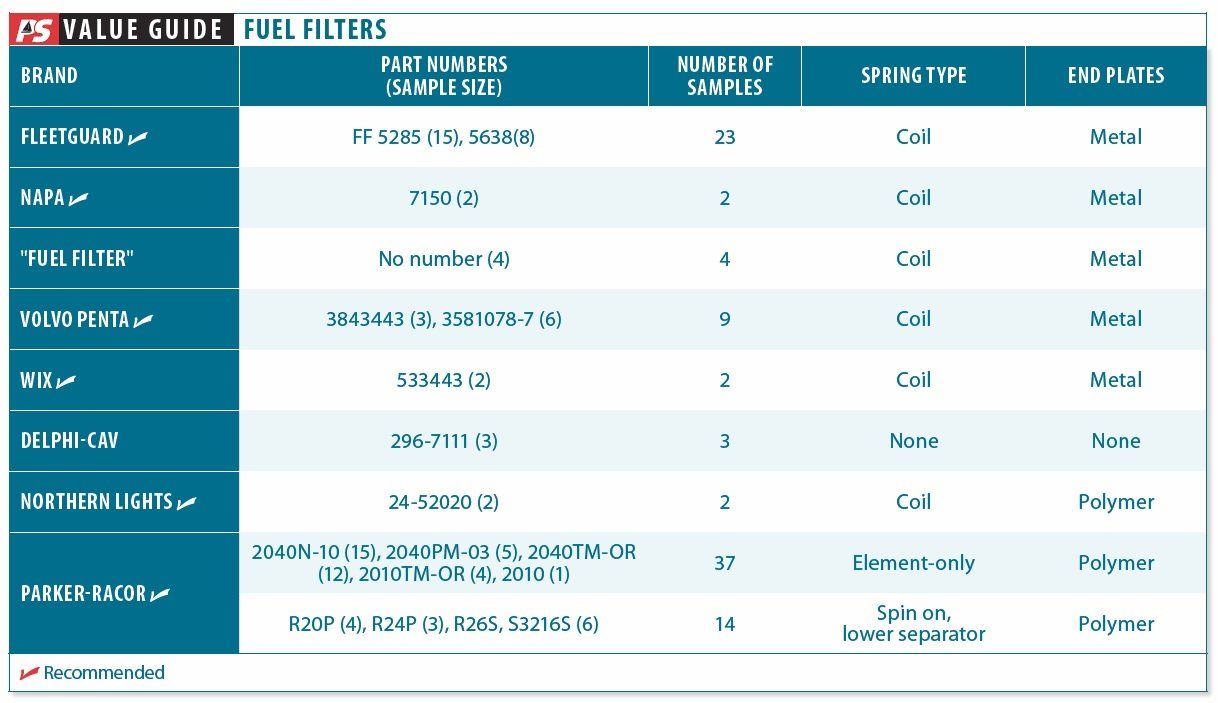

In Marine Oil Filter Comparison Test (PS July 2019) we cut open over 100 used oil filters and learned that most are put together quite well. Internet claims regarding the need for coil springs and metal end-caps found no basis in fact. We found many quality filters that lacked metal end-caps or springs. But we also learned that certain brands had consistent problems with durability or quality control. We wondered if the same was true of fuel filters.

What We Tested

As we did in the used oil filter test, we collected 100 samples from recycle bins and mechanics. We collected both gasoline and diesel filters. Bandsaw in hand, we sliced them open to see what we could learn. (Safety note: we let the gasoline filters dry for two months before cutting into them.)

Observations

Unlike oil filters, we found zero mechanical failures. None. Without the heat and vibration, they simply don’t deteriorate the same way. Oil filters must be changed every time the oil is changed because the filter itself takes a beating, but the practice of leaving fuel filters in place for years is probably OK, so long as the can does not rust out or the filter clog at an inopportune moment. The prudent sailor will change diesel filters each spring, but gasoline filters last longer because there is no such thing as gasoline bug.

Unsure whether the sludge in your filter is relatively harmless asphaltene that has accumulated over the years, or a fast-growing bug infestation? Splash a little bleach on the filter. Bugs will turn white, but asphaltene will be unaffected.

As with oil filters, rebranding is common. No OEM makes their own filters. And as with oil filters, suppliers change over time. We did not attempt to track down the manufacturer of each brand we tested.

Filter Compatibility. All of the major diesel filter manufacturers claim compatibility with biodiesel blends up to B20. We don’t recommend biodesel because of greater risk of bugs, but your filter will be OK. All of the major gasoline filter manufacturers claim suitability for all ethanol blends, up to E95. However, ethanol blends greater than 10 percent (E10) are not approved by the EPA for marine use or by any marine engine maker. Be careful to avoid E15 when filling up.

We are concerned about fiber shedding, just as we were with oil filters. When we rinse the surface of second stage polishing filters, we found that a good portion of the solids were fibers from the first stage. We can only assume that the final filter shed some of its own material into the engine. Synthetic media from Wix, Fleetguard, and Parker are known to shed less, but the actual difference is hard to quantify.

We’ve heard some horror stories for dockmates who bought cheap Racor knock-off elements on the internet. Who can blame them. It’s just a filter and they are expensive. But they noticed that the filters didn’t seem to get as dirty as the Racor elements, suggesting they weren’t catching as much dirt. Not good. Perhaps these discount filters are fine for the first stage of a two-stage polishing system, where what they miss will be captured by the second element. The few off-brand replacement elements we saw were well made, though we did not test the micron rating.

Filter coarseness depends on what you are catching. If you are fighting bugs, a cheap first-stage filter (20-30 microns) can catch the clumps while you warm up to the idea that you really need to clean your tank. On the other hand, if the concern is asphaltenes, they will probably go right through a coarse filter (20-30 microns). See the image of 30, 10, and 2 micron elements from a multi-step polishing system on page 13. Its pretty clear that the 2-micron filter is doing all the work and the others probably have no effect on the 2-micron elements life expectancy.

Which brings us to nominal vs. absolute filter ratings. Filters aren’t like window screens, where you can measure the holes and say this is the biggest bug that can crawl through. It’s a matter of statistics, and different filter manufacturers can chose different rating systems. The higher the percentage at a given rating, the more effective. That rating also changes, as particles clog the media, making the holes smaller.

Banjo Bolts

So named because they resemble a banjo, these hollow bolts allow the fitting of lines into tight spaces without crimping the hose. But they are also notorious for plugging. The internal openings are smaller than the hose, so if something sloughs off the hose, this is where it will catch. There are sharp bends. They can also be the source of hard-to-find air leaks if the gasket has been compressed after too many removal/replacement cycles.

And once in an odd while, you will come across one with an internal strainer. That can lead to a good bit of head scratching; you changed the filter, blew out the hoses, and still the flow seems restricted.

CAV Filters

CAV is part of the Lucas group of companies, specializing in fuel injection systems. You don’t often see these in US boats, but they are popular in the UK. The fuel/water separators we see from Parker -Racor and others function by passing the fuel first through the bowl, where large droplets fall out.

The fuel then reaches the media, where smaller particles are rejected by the oil-coated, hydrophobic media, and fall into the bowl. Finally, the fuel goes through the media and onto the engine. With CAV filters (the initials of Charles A Vandervell), the fuel passes right to the media, where is flows down a along a spiral wound media first, which does not provide positive particle removal. The notion is that it will be followed by positive size filtration down-stream.

The cans are made of thin steel, only 0.012-inch vs. the typical 0.017-inch steel used in other filters. This makes them three times less stiff, and far more prone to denting and distortion during installation. Consequently, they are known to leak. We also noted serious corrosion, made all the worse by the thinness of the metal.

Volvo Penta (part number 3581078-7) and Fleetguard (FF167A) make canisters for the CAV housings. Although we did not test these, from what we see they use the same filter-first flow pattern and the same spiral depth winding, so we can’t recommend them. They may be better made than the ones we tested. Nevertheless, our advice is to swap filters that use the CAV spiral design for a more modern design.

Remember to recycle. Recycle fuel filters along with the used oil filters. This includes gasoline filters so long as you drain them first, and letting them dry isn’t a bad idea.

Conclusions

Unlike used oil filters, we didn’t find any potential troublemakers in this bunch. Well, other than the CAV filters, which we hope you will replace with something better. Change the filter in the spring and move on. If you are changing them much more often than that, clean the fuel tank. It’s good seamanship.

Hello, I run a 2gm20F with an inline Parker R12T ( 10 Micron ). Would there be any + to use a finer one as I read the Yanmar filter on the engine would be rated at 10-15 micron ? I replace both annually.

Thanks

R12T should be a 2 micron filter. Their naming system goes primary, secondary, tertiary. I run a R12S on my 2GM20F and it works fine.

R12P – 30 microns

R12S – 10 microns

R12T – 2 microns