For as long as I can remember, and probably for generations, it has been Chesapeake Bay lore that the longer an anchor soaks the better it will hold. Often an older generation anchor—and perhaps undersized as well—would utterly fail to set when first deployed. However, the sailor knew if he waited 30 minutes before applying significant force, the anchor would dig in and hold through reasonable weather.

The empirical interpretation was that time allowed the anchor to sink through the surface ooze down into the firmer mud underneath it, and that the steady tugging on the rode would also help it settle in. After this soaking period you could gently apply a little reverse and achieve a good set. It was also known that the anchor would improve over time if a boat stayed in one place for days or weeks.

Anyone who has hooked an old tire or branch buried in mud will attest to the powerful suction force that develops over time, but how much is lore and how much is backed by science and testing?

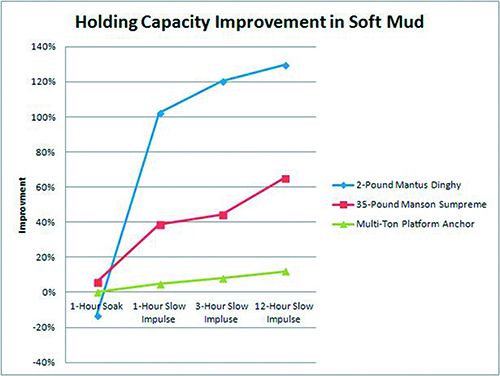

Offshore oil platform anchor manufacturers have studied soil mechanics and anchor extensively. They have studied the effects of both time and cyclical loading on drag anchors, the design type that includes yacht anchors. (Dead weight, piles, and embedment anchors the other types.) They report consistent improvement in ultimate holding capacity and stability for anchors over time and with exposure to slow cyclical loads, ranging from 20-30 percent of the maximum load depending on the combination of factors.

Given the shockingly low holding power of anchors in mud tests, suction or some other force must surely be at work (see “Anchoring in Squishy Bottoms,” PS February 2015). If not, half the fleet would drag every time the wind exceeded 20 knots, and that’s just not what we see.

What We Tested

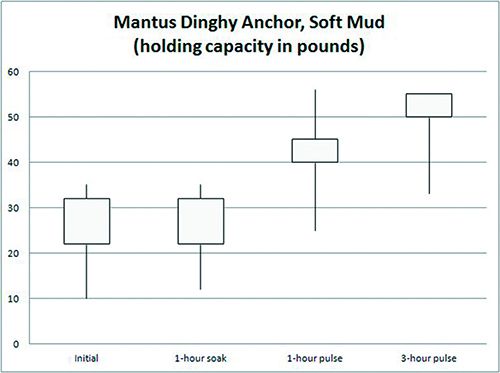

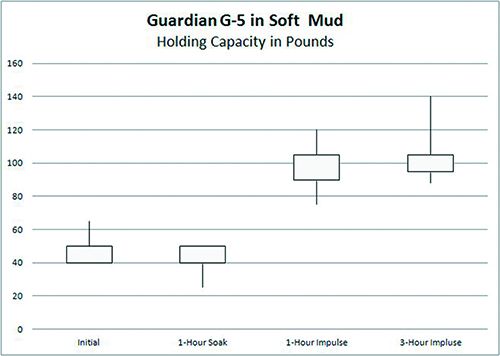

First, we went back to our old friends, a collection of dinghy anchors that we have confirmed to behave in the sand and mud bottoms of our test sites in Chesapeake Bay in a way that can be scaled up to apply to full-size anchors. A 2-pound Mantus Dinghy serves as a representative for scoop-type anchors, a field that includes anchors from Rocna, Manson, and Spade. A Guardian G-5 represented pivoting fluke anchors, which includes the common “Danforth” anchors made by multiple manufacturers including Lewmar, Kingston and others (see “Anchors for Muck Under $200,” PS February 2006). After repeated studies with multiple anchors in these bottoms, we have a solid background in both general behavior and quantitative holding power for these anchors in the soft mud and fine sand of the Chesapeake Bay (see “Small Versus Large Anchors,” PS August 2016). We also tested a 35-pound Manson Supreme. For details on the testing protocol, see “How We Tested,” on page 21.

Observations

Soaking alone made no appreciable difference. This is not surprising, since the 2-pound anchors were just sitting on top of the ooze and the 35-pound Manson Supreme only sank about 3 inches. The mud may be soft, but there is a lot of surface area to support the weight. Anchors that had soaked for an hour did set more quickly, but the final holding capacity was no different than if the anchor had been set gently when first deployed. The idea that just letting an anchor sit will improve holding is a myth.

However, if the anchor was lightly set soon after deployment and significant time was allowed to pass, holding dramatically improved. In actual practice, we doubt many anchors are ever simply soaked and allowed to settle; the boat drifts back against the anchor and causes a little digging, and then the wind pulses every 5-20 minutes, adding more encouragement. This supports generations of Chesapeake Bay sailor experience.

- Gray blocks show the average range of maximum hold for the Mantus Dinghy Anchor. Long duration “pulses” applied after 1 to 3 hours proved effective.

- Gray blocks show the average range of maximum hold for the Guardian G-5. The anchor’s average maximum hold saw little or no improvement after 3 hours.

- The test arrangement ensured that the direction of the load would remain relatively constant throughout the test.

Our test boat, a 34-foot catamaran, became our test platform. Securely anchored in a number of soft mud locations, we pull the smaller anchors toward it using the primary winches.

First, as a control, we tested each of the 2-pound anchors by measuring holding capacity when set immediately after deployment using a slow, steady pull. We also tested the holding capacity of anchors that had been left to soak for an hour without any initial set; this was to establish if settling time alone made any difference.

We tested short period cyclical loading, akin to waves and swell by loading and unloading with a winch 10 times in 5-10 second bursts of 50% holding capacity. We then tested anchors that had been set 10 minutes after deployment to 70% of the holding capacity determined in the “control” test, and allowed each to soak without loading for 1-hour and 3-hours. We then pulled each of these examples until they dragged.

Finally, we tested the effect of cyclical loading over a period of hours, trying to mimic the effect of moderate wind and wave action. Again, each anchor was set to approximately 70% of the holding capacity, as determined by the first test. However this time, we applied cyclical loading two ways; by pulling with a winch 10 times for 30 seconds with one minute rest between pulls to simulate wave action, and also by allowing the small anchor, set as a stern anchor, to take the side load as the boat gently yawed from side to side in a light variable wind, simulating wind load fluctuations.

Again, at the end of the time period, we then pulled the anchors until they dragged. This was repeated at least four times. We then repeated this testing with a 35-pound Manson Supreme in soft mud. As with all anchor testing and in soft mud, variability is the rule.

We moved our test boat a few times so as to test in muds of slightly different consistency. We recorded the maximum tension, but all data analysis and plots reflect the tension 30 seconds after the winching stopped because this holding is a better measure of anchor holding and stability.

Mimicking the wind

In our testing, short pulls on the rode reduced or had no effect on holding capacity. This suggests that without some intervention from the sailor, this pulsing wave action can actually be harmful. Based on our observations and other studies, this is because there is not enough rest time between pulls for the soil to consolidate. The net effect was weakened soil with reduced holding.

However, very slow pulls with long rests in between, like those produced by summer sea breezes, generally increased holding capacity. Improvement ranged from a low of no change (2-pound Mantus with a set-and-soak for one hour in soft mud) to a high of 500 percent (2-pound Mantus after 3 hours of slow cyclical loading in soft mud). The average improvement after 3 hours of slow cyclical loading in soft mud was 122 percent (see page 21, “Slow Pulse Your Way to Better Holding”). The 35-pound Manson Supreme showed an 80 percent improvement. Sailors will see less improvement in firm bottoms and less as the anchors get larger. In oil industry tests of multi-ton anchors, the improvement with time and cyclical loading is generally 20 to 25 percent.

Our theory, specific to the soft mud of the Chesapeake, is that pure downwards settling adds only a tiny contribution, while the real mechanism that improves holding is compaction and stiffening of the layers above the anchor. This gives the broad tail portions of the flukes improved grip, causing them to penetrate both deeper and more directly that if the anchor is just dragged along the surface.

A common setting problem with anchors is that when the density of the soil increases quickly with depth and the surface material is weak, the wide trailing portions of the fluke can’t generate enough downwards push to force the toe deeper. A region of compacted soil above the anchor solves this dilemma and result is remarkable improvement. This also explains why a long resting period between pulses is mandatory; the soil needs time to consolidate between pulls. The reason we saw much greater improvements than reported for oil platform anchors is simply that we are working in unconsolidated layers near the surface, while the multi-ton anchors are already much deeper, in firm soil.

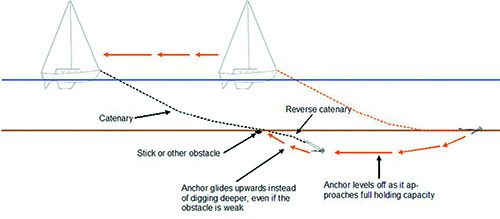

What causes this great variability? The assumption has always been that buried trash and weak areas in the mud are the culprits. In our testing, the cause of holding failure, if we dragged far enough, was nearly always a stick in the mud that guided the rode of the buried anchor back to the surface. It didn’t need to be a strong stick, only enough to change the pull a little bit, creating the effect of short scope. Although sticks never came to the surface with the anchor, each time we dove on the anchor after failure, it was still there, snapped or pushed to one side. When the anchor reached the surface the anchor would suddenly lose grip and surge out of the bottom, the result of energy stored as rode tension.

Veers, Resetting, and Dragging. Since the solid consolidation that occurs as a result of the passage of time and cyclical loading is a local effect, how does the reinforcement we measured in forward pulls relate to pulls at an angle? Veering has not been extensively studied by the platform anchor folks because their anchors are not subjected to veering loads. They are multipoint anchors and the anchor only sees a load in one direction. Additionally, many of the large anchor designs are comparatively fragile when exposed to side loads and can easily be damaged during deployment or recovery if loaded from the side.

First, the consolidation effect is primarily in front of the anchor, though it does seem to proceed to the sides as well, though to a lesser extent. Second, the larger portion of the holding capacity improvement is not from soil consolidation so much as deeper setting.

In the veer testing we did it seemed that in a gradual shift of up to 120-degrees, the anchors smoothly rotated and had effectively the same strength as before the shift, indicating the anchors stayed down and that the increase in holding capacity is relatively durable. The force required for recovery seemed to be in similar proportion to the final holding capacity. Weak anchors came right up, and even the little 2-pound Guardian required using the dinghy engine to recover it from every good set; no amount of arm power I could muster in a tippy inflatable was going to make it budge.

Scope counts. We did a few trials at shorter scope using rope rode. There was no improvement over time, most likely because the upward tugging prevented the anchor from going deeper. Additionally, a shallow anchor agitates and softens the overlying soil. Although we understand the arguments for shortening scope in crowded harbors, in soft mud this must be delayed until the anchor is well-set, which may be hours.

The downside of this slow, deeper setting is that if the anchor is pulled out and required to reset, you’re starting all over again. This can happen if there is a strong 180-degree reversal in direction or if the anchor is simply overpowered. Dragging into a stick—and they are common in mud—will pop the anchor out.

Once it rises back up to the top layer of soil, it has to start digging all over again, and it will not have time to progress through the graduated three-hour setting process. As a result, it will have only half the holding capacity it had before it was ripped loose, and is likely to drag across the harbor and alarming rate.

Additionally, mud will clog the flukes of scoop anchors and will jam the pivoting flukes on Danforth-style anchors, so unless you lift the anchor and rinse off the clumps, your chances of resetting are significantly reduced. It is better to make sure you don’t drag. But just how do we accomplish this?

If the risk is the approach of a storm, try setting the anchor in the direction of the greatest anticipated wind. Alternatively, you can set two anchors in a tandem V (see “Tandem Anchoring,” PS August 2016). In soft mud in violent weather, this may be the only practical way to ensure good holding power, and still take full advantage of your anchor’s deep-setting power. For tips on setting individual anchors see the adjacent article “Setting Anchors in Soft Mud.” For tips on using the engine on smaller boats to achieve a good set, see our November 2018 report, “Setting an Anchor on a Small Boat.”

Multi-million dollar oil rigs rely on the same physics that apply to the anchors in our test, so there is plenty of data on anchoring technique.

Our test generally mapped the protocols used for testing much larger multi-ton platform anchors, but our smaller anchors recorded much more significant improvements in holding power than the big oil-rig anchors.

This is likely because oil platform anchors have good initial sets because they can sink deeper into firmer, better holding soil, while the lighter yacht anchors’ initially set

The adjacent graph shows the results of slow long-duration pull-tests with a 2-pound Mantus Dinghy Anchor (blue), a 35-pound Manson anchor (red), and data from a study of similar oil rig anchors (green). The time intervals indicate the interval between slow, long duration cyclical loads that testers applied to mimic a boat backing down, or the effect of summer wind patterns.

Conclusions

In soft mud, the ultimate holding capacity for full-scale anchors typically improves 50 to 75 percent over time as a result of the steady tugging of the wind. The obvious corollary is that it pays to anchor early, at least a few hours before the thunderstorms hit. To use your engine or sails to back down and set the anchor, you should wait at least 15 minutes. For better results, you can wait longer and potentially repeat the process after several hours.

The only way to know how well an anchor is set is to test it vigorously, and you should calculate what “vigorously” means with your boat in relation to wind speed. If the rode does not stay on the bottom (long scope or chain in deep water), the additional setting and consolidation may not happen. Shorten up later if you must, but consider staying at long scope for at least a few hours and then shortening up before dark.

Additional testing of veers and reversals of full scale anchors is needed; it is uncertain how this deeper setting translates into security during wind shifts. We think it helps, because the anchors are deeper, but we’re not sure how much.

In some trials, the result of trash near the anchor, there was no improvement. Anchoring in mud is always variable.

Just as the strength of steel depends on its temperature history, the holding capacity of an anchor relates not only to anchor design, bottom material, and scope, but also to the entire setting and load history of the anchor. Just one more piece of the anchoring puzzle.

Drew Frye is technical editor for Practical Sailor and author of Rigging Modern Anchors ($20, Seaworthy Press). He gets plenty of opportunity to test soft-bottom anchoring in Chesapeake Bay.