Sanitation systems aren’t the sexiest part of sailing, but they are, well… necessary. And although the risk of transmission of COVID-19 through means other than airborne particles is poorly understood, the pandemic is bound to prompt communities to take a closer look at how we handle onboard waste.

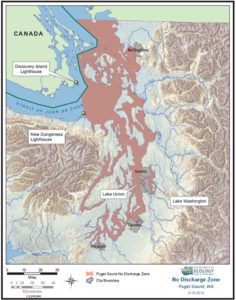

In a move that pre-dates the COVID-19 pandemic, Anne Arundle County has applied to the EPA to declare nearly all of the tributaries a no discharge zones. In some parts of the country, No discharge zones (NDZ) are regarded as a political distraction—a way to blame boaters for what is actually a land-based problem. But in the Chesapeake Bay they generally find support in the sailing community, and that is the case this time. I’ve long kept boats in Herring Bay, located at the southern tip of Anne Arundle, which has been a NDZ since 2002. That effort was driven by a local marina, and on balance, supported by local boaters. They liked the idea of improved water quality, whether real or perceived.

But NDZs will always be a political football, and arguments become distorted and facts misrepresented. Let’s try to make this a no-spin zone. We’ll be breaking things down per person to avoid the enormity of cities, drainage areas and wastewater treatment plants. It’s too easy to become disoriented by big numbers.

It’s easy to argue that one boat will make little difference, just as my vote will make little difference in the outcome of a political election. Individually this is true, but collectively it is not. We’ll also compare treatment efficiencies to established standards. Whether they are appropriate or not, they’ve been agreed-upon by our society.

We also understand that pump-outs add both cost and labor, beyond that experienced by land dwellers and implicit in sewage treatment standards; if the costs in dollars and personal labor were the same on land, standards might be a little different. We will ignore malfunctions, and non-compliance of both onboard and land-based treatment works. They both happen, they’re both infrequent, and the daily impacts per person are probably equal.

What is a No Discharge Zone?

An NDZ is an area where neither treated nor untreated sewage may be discharged. Discharge of bilge water and gray water is still permitted.

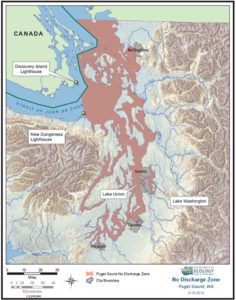

In the absence of an NDZ, untreated sewage may only be discharged more than three miles offshore and not within the inland waters of the United States. Most bays and sounds—the Chesapeake Bay, Delaware Bay, and San Francisco Bay, for example— fall within the three-mile line and are considered inland waters. The Puget Sound is a different case, since it is shared by Canada and is not, thus, an inland water.

Sewage treated by a Type I or Type II Marine Sanitation Device (MSD) may be discharged within the 3-mile limit unless restricted by an NDZ. Restricted to vessels 65-feet or less, a Type I flow-through treatment device commonly uses maceration and disinfection for the treatment. A Type II flow-through treatment device may employ biological treatment and disinfection. A Type III device stores wastewater in a holding tank until it can be pumped out or legally discharged offshore. (See the table comparing MSD types on page 6).

The Raritan Electro Scan, the most popular Type I MSD, sanitizes waste by first macerating with a mixer to reduce particle size, and then killing or deactivating microbes by exposure to hypochlorous acid. Hypochlorous acid is generated by electrolyzing seawater, which contains sodium chloride. Chlorine gas is generated, which immediately converts to hypochlorous acid in water. This process takes about four and half minutes. The EPA and Coast Guard have tested the process.

NDZ Positives

Proponents say that no discharge zones improve water quality. Let’s break this down by pollutant.

Reduced Bacteria. Type I MSDs effectively kill or deactivate microorganisms, reducing the effluent to a maximum of 1000 colony forming units (CFU) per 100 milliliters (ml). Actual results are less and compare favorably with the typical 35 colony-forming units required for swimming areas.

In ocean water, salt rapidly kills most pathogens (other than cholera). That said, the back creeks in the Annapolis areas are barely saline, some less than 5 parts per trillion (ppt), a level bacteria can thrive in.

Additionally, the limit is 15 CFUs for shellfish harvesting, which was finally reinstated this year in the Herring Bay area, an NDZ just south of Annapolis. Was this change related to its NDZ status? Probably not, since Herring Bay has been an NDZ since 2002. Since discharge by Type 3 (holding tank only) MSDs is already prohibited within the 3-mile limit, simply adding NDZ status has no effect on microbial contamination.

Bottom line: This argument is false.

Reduced Biological Oxygen Demand (BOD5). Biological oxygen demand is a five-day test measuring the amount of oxygen bacteria consumed while degrading the waste. Ordinary sanitary sewage averages about 250 ppm BOD, but it includes dilution with water from dishwashers, washing machines, sinks, showers, and toilet flush water. Boat waste is about 10 to 20 times more concentrated, averaging about 2,500-5,000 BOD based on testing by the EPA and by Practical Sailor sampling.

MSD Types

| TYPE | DESCRIPTION | EFFLUENT |

|---|---|---|

| TYPE I* | Flow-through treatment devices that commonly use maceration and disinfection for the treatment of sewage. (limited to vessels less than or equal to 65 feet.) | • No visible floating solids • A fecal coliform bacterial count not greater than 1000 per 100 milliliters |

| Type II | Flow-through treatment devices that may employ biological treatment and disinfection. (Some Type II MSDs may use maceration and disinfection.) | • A fecal coliform bacterial count not greater than 200 per 100 milliliters • No more than 150 milligrams of total suspended solids per liter |

| TYPE III | Typically a holding tank where sewage is stored until it can be discharged shoreside or at sea (beyond three miles from shore). | No performance standard; must "be designed to prevent the overboard discharge of treated or untreated sewage or any waste derived from sewage" (33 CFR 159.53(c)(PDF)(2 pp, 163 K)) |

With the Electro Scan, some of the hypochlorous acid used to kill bacteria also reacts with other organic chemicals present, resulting in a slight reduction in BOD and the production of chlorinated organic by-products. The reduction in BOD is variable, on the order of 10 percent, which compares poorly with the typical 90-95 percent reduction achieved by conventional sewage treatment. Of course, the importance of a few pounds of biological oxygen demand is debatable. The impact would be no different than the same amount of food thrown into the water or some falling leaves.

The potential negative effect of chlorinated organic residuals created by the reaction of bleach with untreated sewage is concerning but has not been systematically investigated. We’ll assume the benefit of a slight reduction in BOD and the risk of chlorinated residuals are roughly offsetting, and conclude that a Type I MSD has no beneficial effect on BOD.

Bottom line: This argument is true but very weak and fails any cost/benefit analysis.

Reduced Phosphate. Conventional sewage treatment reduces phosphate by only 1-2 parts per million (ppm) or about 25 percent of the influent concentration. Advanced sewage treatment plants can remove up to 80 percent of the phosphate. The phosphate is absorbed into the bacteria, and when the bacteria are settled from the water and disposed of as sludge, they go to the landfill. A type I MSD cannot remove phosphate, since as an element, it can neither be created nor destroyed, and nothing is physically removed by the MSD.

Phosphate greater than about 0.1 ppm can lead to algae blooms. About 0.016 ppm is normal in seawater. Phosphate in boat wastewater ranges from 30-60 ppm, based on EPA and Practical Sailor testing.

Bottom line: This is possibly a valid argument for a poorly flushed body of water, although the impact is tiny and the cost/benefit argument is questionable (see “reduced nitrogen,” below). This is probably a false argument for more open waters, since most treatment plants don’t remove much phosphate.

Let’s assume we have a Raritan Electro Scan plumbed between our head and a thru-hull. We don’t have a holding tank, but now we’re going to need one, because we can’t discharge at the dock. What are our options?

In most NDZ situations, shortly after leaving the dock we will be outside the NDZ and can operate our flow-through, Type I or II MSD. In a few more miles we will be outside the declamation line and can discharge untreated sewage. We really only need a holding tank for use at the dock.

In many lakes, rivers and the Puget Sound, we may very seldom or never leave a NDZ. We might as well just have a holding tank and work pump-outs into our schedule. Or in the case of the Chesapeake Bay, the NDZs are small, but the entire estuary is inside the 3-mile declamation line. We’re going to need enough holding tank capacity to serve while at the dock or in harbor, but we can treat through the Type I MSD once in the main Chesapeake Bay.

Holding Tank. The tank must be located before the Type I MSD because we can’t hold the waste after treatment. Although chlorine-treated, the effluent is not sterile and will go septic after sitting for a time. We have three options:

- Raritan Hold-N-Treat. This upgrade includes a 15- gallon holding tank. When activated, a transfer pump treats the waste through the Electro Scan one batch at a time. While we are within an NDZ a switch allows we to disable the processing unit. Fifteen gallons should be enough for overnight, and it can be plumbed for deck pump out. This is a good solution if we don’t live at the dock.

- Holding tank after the head. This system, fitted with a Y-valve to select between holding and treatment, is a good solution if we will be heading offshore and don’t care to treat all of our gallons through the Electro Scan.

- Holding tank between the head and the Electro Scan. Sensors attach to the holding tank, and like the Hold-N-Treat, a transfer pump allows us to treat the waste one batch at a time. Contact Raritan for the particulars of connecting the sensors to our existing Electro Scan. Older units may need updating first. This is a good solution for boaters that spend significant time at the dock and don’t often see the ocean.

Salt System. Remember, the Electro Scan MSD requires 50 percent salinity or be provided with a saltwater feed tank and system. Typically, a 2 or 4-gallon tank and feed system is required. Fail-safe monitoring that is built into newer models will trigger a “low electrode amps” warning or error when salinity is too low.

Reduced Nitrogen. Urine is a leading source of nitrogen, and boat waste contains 15-30 ppm. A Type I MSD will oxidize a portion of the ammonia to nitrate, but none of the nitrogen is actually removed. Bacteria in a conventional sewage treatment plant oxidize nearly all of the ammonia to nitrogen. In fact, bacteria in the natural environment will quickly convert the ammonia in urine to nitrate.

However, only advanced treatment plants employing anoxic denitrification reduce nitrate by converting it to nitrogen gas. Nitrate levels of about 1 ppm contribute to algae blooms. About 0.7 ppm is normal in seawater. Combined nitrogen in boat waste is about 15-25 ppm based on EPA and Practical Sailor testing.

A recent NDZ application listed the incremental cost to remove nitrogen with best available practices as $3,500 per pound of nitrogen removed. In that same NDZ application, that put the estimated value of any reduction at $8,900 per boat each year. However, another department in the same state found that you could achieve a pound of reduction for only $9 by simply changing certain agricultural practices.

According to the EPA, the average person contributes 0.095 pounds of nitrogen per day. Based on the lower cost estimate ($9 per pound), the daily impact is about 86 cents per person. Phosphate reduction has similar net cost, so the total daily impact is about $2 per person. More on cost/benefit in the “negatives” section.

Bottom line: This is a valid argument for a back creek, although the impact is tiny and the cost/benefit is questionable. It is probably a false argument for more open waters.

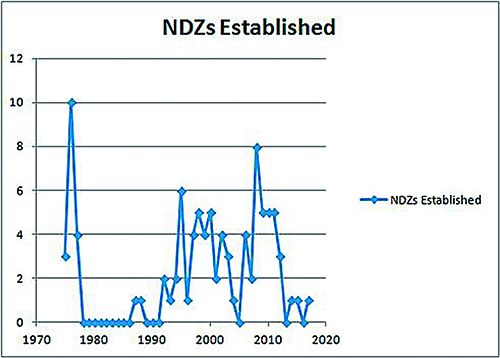

waste to the holding tank or overboard. While a well-designed system will provide

years of service, the DIY result is often a pretzel-like series of poorly-clamped hoses,

and multiple diverters such as this one, which also lacks a vented loop for the inlet.

2. Raw-water inlet and outlet lines need anti-siphon vents. The vent must loop

above the waterline at all angles of heel.

3. Early holding tank designs had leak-prone outlets at the bottom of the tank and often lacked a deck-level pumpout fitting. Similar systems, with the addition of a

deck pumpout, are common today. Ideally, a system should not trap waste in any of the lines. Trapped waste will exacerbate a odor problems.

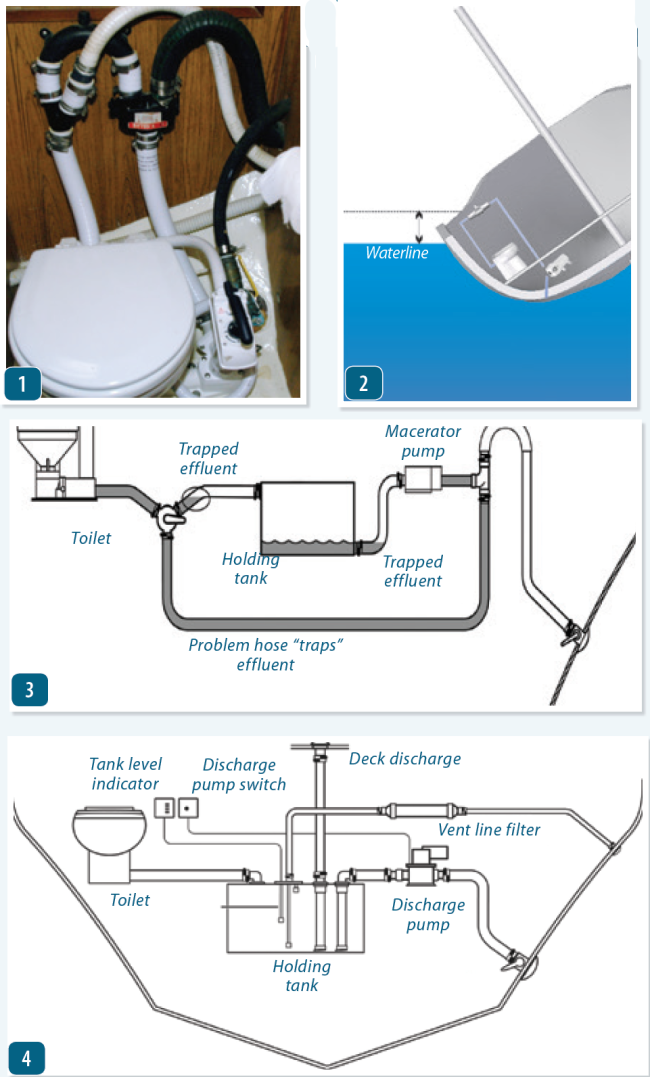

4. At the other end of the design spectrum are systems tailored for areas where

pumpout facilities are readily available, like this one from Dometic. Instead of a

Y-valve, multiple check valves prevent back-siphon.

There are many ways to treat waste aboard a sailboat and still comply with local health and environmental regulations. Practical Sailor has tested all of them at one time or another. In addition to either raw-water or freshwater plumbed toilets, there are portable toilets, composting toilets like the Air Head, hold-and-treat systems like Raritan’s Lectro Scan, and vacuum-based systems like Sea-Land’s VacuFlush. In addition, there are multiple ways to plumb a holding tank into the system.

Most manufacturers of marine toilets offer selection and installation guides on their websites. They also will offer a range of products (adapters, low-profile pumps, etc.) designed for specific installation scenarios. Two good resources for do-it-yourselfers contemplating an upgrade are Nigel Calder’s “Boatowner’s Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat’s Essential Systems,” and Peggie Hall’s “Get Rid of Boat Odors: A Boat Owner’s Guide to Marine Sanitation Systems and Other Sources of Aggravation and Odor.”

Follow the installation instructions carefully. Pay special attention to discharge sanitation hose size and electrical wire gauge. There should be no more than 3-percent voltage drop in the wire run. These units have high start-up demands, so sizing for the smallest acceptable gauge is not wise. The two most common causes of poor performance are lack of water and insufficient power, both of which can lead to clogging.

Raw-water inlets for raw water flush toilets or outlets plumbed directly to through-hulls should have vented loops to prevent water from siphoning back into the head. This loop is placed after the inlet pump. If it is placed before the inlet pump, a shut-off solenoid may be needed to prevent air from inhibiting pump performance.

NDZ Negatives

All boats in an NDZ that have a marine head must have a holding tank. This can be plumbed before the Type I MSD (see page 21), so that you will have the option of either a pump-out or using your onboard treatment system. Depending on what is required and whether you do the work yourself, this could run $200-$3,500 with a 20-year life expectancy (7 years for the hoses). Space can be a problem.

Bottom line: A valid point. If you don’t have a holding tank, you’ll have to add one.

City sewers are worse than MSDs. Most sewage overflows are caused by combined sewers, where storm water and sanitary waste flows into the same pipe, and are transported to the sewage treatment plant by a lift station pump. Lift stations can overflow if the rainfall exceeds pump capacity. However, since few boaters pump out in downpours, our sewage is rarely part of this overflow.

Bottom line: Unless you pump out in a deluge, your waste will reach the treatment plant. This is a false argument.

Conclusion

As more and more boaters are being asked to stop onboard treatment, it is important to understand the cost and benefits of making this change, and impacts can vary widely by location.

While this article is a good treatment of the topic at hand, there was no mention of composting marine toilets. They may be a bit more work, but given the choices are a viable alternative.

Yes, composting/desiccating heads are an option. They are particularity attractive for lakes and other inland waters that may have few or no pump-out facilities. Urine still must be carried ashore. See Practical Sailor review, “Composting Marine Heads,” November 2002.

WAG (waste alleviation and gel) bags can make sense for smaller boats, or as a back-up plan for a clogged head. See Practical Sailor “Porta Potty Perfumes,” September 2018.

Your quote:

“Bottom line: A valid point. If you don’t have a holding tank, you’ll have to add one.”

Doesn’t a porta-potti have a holding tank. Are you saying these are no longer legal?

Hi Drew,

With a raw water toilet how can you have a vented loop on the water intake? When you pump water in through the intake line to the toilet isn’t it the case that you would only suck air though the vent in the loop?

Good question. In fact, many toilets have the vented loop installed incorrectly. I even saw this in Sail Magazine!

The attached instructions show that the vented loop is NOT between the intake and the pump, but between the pump and the bowl. The hose that is factory installed must be discarded and replaced by one that goes up to the vent and back down.

https://cdn11.bigcommerce.com/s-g7o41rcupc/content/files/toilet%20vented%20loops.compressed.jpg

I’ve had my composting head for fully 2 years now. There was a brief learning curve, but I would say that the most important preparation for me was a bit of actual home-gardening and composting experience. That’s a whole other story. I just want to say that I have been truly amazed every step of the way at how easy it is to live with a composting head. It actually seemed too easy at first, but we’ve gotten used to it being that way. There is no question it has been less work than the old marine head we’ve been using for decades in our cruising sailboat. I get that there are some popular misunderstandings about composting heads — I used to buy into those myself. But I am kind of waiting now for everybody else to discover the real joy and ease of no longer producing sewage on their boats at all. And no more smell! No thru-hulls! No holding tanks! No macerator pumps! No pump-outs! Seriously I could go on and on.

Coincidentally, we have a review of the best absorbents and urine deodorants for composing and desiccating heads in the que as we speak. Also reviewed are compact desiccating heads and kits for small boats. We’ve been impressed by how well they work and will be recommending them for many applications. Ease of operation in a zero discharge zone is one of the advantages.

We’re not as sure about composting heads for larger and ocean-going boats. Conventional heads and holding tanks have their strengths.

A portable toilet with integral holding tank is acceptable in a ZDZ.