Anal About Cleaning?

We’re not sure about this. However, any marine innovator deserves a Warhol moment or a day in the sun. So meet Mark Hudson, a 38-year-old cabinetmaker who sails a Catalina 30.

Hudson says his new Rig Rover™ is for cleaning your wire rigging. He has a patent pending.

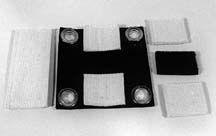

The Rig Rover is a stout piece of Sunbrella® to which are affixed with Velcro™ a piece of flexible nylon brush made by 3M and two squares of heavy (it’s doubled twice) cotton duck. The brush loosens dirt; the coarse cotton collects it. In each corner is a heavy brass grommet.

Along two edges of this 5″ square assembly are additional strips of Velcro that permit you, after squirting some kind of cleaning fluid on the brush, to fold and clamp the whole pad over a wire. Hudson recommends mild soap; we suggest any good metal cleaner.

Attach a halyard and a downhaul, and, after some beneficial arm exercise, the wire is clean…and you’ve never left the deck. When you fold the pad on the wire, you might want to add initially a couple of ties through the grommets. The pad is very stiff and wages war with the Velcro strips.

If you use soap, Hudson includes another canvas pad that can be soaked and used to rinse the wire.

Asked what to do about the shrouds above the spreaders or a split backstay, Hudson said you can clean 75% of the rigging from the deck and that, to get the topmost sections of wire, the Rig Rover is easy to attach from a boatswain’s chair.

We don’t think we run a slack ship and certainly not a dirty one. So the need for the Rig Rover (at $29.95) doesn’t seize us by the throat. On the other hand, Hudson lives at Marina Del Rey, where boats stay in the water all year ’round, and should know a thing or two about how dirty boats can get. He says dirt begets corrosion and that’s not good for rigging. (New Wind Corporation, Box 11991, Marina Del Rey, CA 90295, 310/827-3598, fax: 310/827-3628, www.rigrover.com.

Snot’s Back in the Lexicon

Modern epoxy is tough stuff. Despite the fact that there are now available some powerful, high-tech glues, epoxy still is preferable in lots of common applications.

Epoxy, thickened with fillers, also has replaced many putties, fairing compounds and fillers…as long as the epoxy is protected from sun.

The vaunted strength of epoxy is said to be greatly enhanced by the addition of fiber—glass, carbon, Kevlar™, tiny cotton bits, wood shavings, sanding dust (which can give it the proper color), etc. On crude jobs, we’ve even used a handful of lint from the clothes dryer filter.

Paul Oman, of Progressive Epoxy Polymers, is now putting up in 1- and 2-quart kits a fiber-reinforced paste that can be used for gluing or filling. He calls it Boat Snot. (“Snot” is an old shop name used by GRP pioneers for a mixed-and-ready batch of epoxy.)

Oman’s stuff can be used above or below the waterline. Even better, it is mixed in a 1:1 ratio, which Oman says “is forgiving enough to eye ball.” It also contains microballoons to make it easier to sand.

Boat Snot goes for $28 a quart, $53 for the 2-quart kit, shipping included.

Oman also makes other specialty epoxies, such as sealers (for barrier coatings), gelled epoxy for vertical surfaces, repair mats, Kevlar paste and a choice of fast-cure/slow cure and anything in between. ( Progressive Products, 4607 Linden Pl., Pearland, TX 77584, 281/997-9872, [email protected] or www.epoxyproducts.com.)

About That Sun Business…

We’ve been told often that epoxy doesn’t like direct sunlight, but it’s always a somewhat vague warning.

So, in our usual ultra-scientific fashion, we’ve been checking epoxy’s vulnerability to solar degradation.

A few years ago, we had a small plastic container that was used a half-dozen times for mixing small batches of epoxy for little repair jobs. We wound up with a simple plug of epoxy built up in layers in a small plastic container. Easily jarred loose from the container, the epoxy cylinder (2-1/2″ D x 5″ H) seemed like a natural for testing.

It has been getting a half day’s sun, winter and summer, on our back porch now for about three years. We test it occasionally by trying to break apart the layers and by dropping it on the sidewalk. Nothing seems to have happened to it.

It’s not even getting cloudy, which is what we’ve been told foretells failures, especially if the epoxy layer is thin.

We’re not saying, “Taint so.” We’re just watching.

The same thing is said of polypropylene line. The sun destroys it. Somebody once gave us a piece of 1″ yellow polypropylene. We made of it a single-strand swing with a round seat with a hole in it and hung it from a tree. The tads loved it; the boys gloated because, despite the rope being slippery, they learned to climb it.

Until one day, in the third summer, when one of the shavers muttered an oath and shook his hands. Examination revealed that the outer strands of the rope were parting in large numbers. It was not pleasant to run a hand up and down the rope. It had happened suddenly. The polypropylene was replaced with a piece of nylon.

So, perhaps the epoxy plug mentioned above will shatter completely one of these days.