Exposure Test Results: Varnishes, Teak Oils, and Other Exterior Wood Coatings

Exterior wood finishes-including one-part varnishes, two-part varnishes, synthetics, sealers and stains, and teak oils-were evaluated one year after application. Testers rated the wood finishes on ease of application, the integrity of the gloss and appearance, and how they fared over the 12-month period during which they were exposed to Florida sun and weather. Testers looked at color retention and gloss retention. After a year, 20 of the original 22 one-part varnishes were still performing well, and all six of the original two-part varnishes remained in the running. Varnish alternatives like teak oils and teak sealers struggled to make the 12-month cut, but the Cetol-coated panels still looked good. Products that were doing well 12 months after application included Interlux Cetol Marine and Cetol Marine Light, both with the clear gloss overcoat; Pettit Clear High Gloss and Pettit Wood Finish; Interlux Perfection; and Nautiking NautiThane.

Topside Paint Exposure Test Checkup

In August 2008, Practical Sailor launched a topside paint test in search of a high-gloss, easy-to-apply, durable coating for fiberglass hulls. The initial report focused on the application characteristics for 29 topside paints, including multiple white coatings and a handful of colored topside coatings. This report taps the best topside paints after their being exposed to the New England weather for a year. Testers rated each paints appearance, abrasion resistance, scratch resistance, hardness, and stain resistance. PS compared seven enamels, 12 mono-urethanes, eight two-part linear polyurethanes (LPUs), and two water-based paints. After 12 months exposure, the majority of the topside paint test field was holding up admirably. Test paints included products from Interlux, Crystalac, Epifanes, Insignia Coatings, Kirby Paint Co., Pettit, Sherwin-Williams, Signature Finishes, and West Marine.

Affordable Marine Antifouling Paint

Practical Sailor tested bottom paints from seven major makers of boat maintenance products. In this report, we compare the 12-month performance of 39 ablative paints and 31 hard paints. We also offer the test results of 18 antifoulings after 24 months in the water, and rate the top specialty antifoulings in specific niches, such as eco-friendly bottom paints, aluminum-safe paints, race-ready antifoulings, fast-drying bottom paints, and budget bottom paints. The bottom paints were tested in both Florida and Connecticut waters. The manufacturers include Alwgrip, Blue Water, Epaint, Flexdel, Interlux, Pettit, and Sea Hawk. Some of the best bottom paints included Epaint EP-21, Pettit Hydrocoat, Epaint ZO, Blue Water Kolor, Interlux Fiberglass Bottomkote, and Sea Hawk Sharkskin.

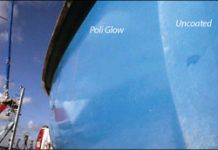

How Do Acrylic Finishes Hold Up Compared to Boat Waxes?

Our July 2009 issue compared 26 bottled waxes and gave an update on our test of 10 traditional paste waxes. This month, we offer a one-year checkup on acrylic coatings. Acrylic coatings differ from paste waxes in their chemistry and how they are applied. Acrylic finishes penetrate pores and chemically bond to the boats surface. We tracked down seven products, applied them to our blue-hulled test boat, and rated them at the one-year mark. Products tested were Vertglas from Lovett Marine, Poli Glow, NewGlass2, Star brite Glass Cote, Klasse High Gloss Sealant Glaze, Higley FiberGloss Restorer, and Presto Gelcoat Rejuvenator.

Practical Sailors Gear of the Year 2009

Practical Sailor editors pored over the dozens of products reviewed in the previous months to find the best of the best sailing gear, products that are worthy of the designation Gear of the Year. This years editors choice list includes a rugged rope clutch (Spinlock), a grippy ratchet block (Ronstan), feature-filled VHF handheld radios (Standard Horizon and Cobra), high-quality nesting cookware (Magma), a proven paste wax (Collinite), an ocean-ready first-aid kit (Adventure Medical Kits), a reliable LED bulb for cabin lighting (Imtra), an economical ice box conversion kit (Frigoboat), an innovative ultrasonic tank sensor (BEP Marine), cold-weather gloves (Gill), and an easy-to-install Wi-Fi booster (5mileWiFi).

PS Advisor: ‘Weathered’ Teak

Isn’t there an old adage about rousing the rain gods by opening a can of varnish (or paint)? Having lived (and sailed) mostly in sub-tropical climes, we can definitely sympathize with a rain-delayed boat project. The rain actually isn’t doing any harm to the wood or varnish so much as it’s just a nuisance, adding more work and time to the job at hand. After the rain ceases, let the wood dry for several days. The higher the humidity, the longer the dry time. Denatured alcohol or Naphtha can remove surface moisture. Once the wood has dried, you will need to resand any bare wood areas so that you’re coating fresh wood.

DIY Topside Paint Test: Two-part Linear Polyurethanes Face Off

While our topside paint panel test (Practical Sailor August 2008) seeks out the most durable topside paint, this test was to determine which two-part LPU is the most user-friendly for the amateur painter and whether the project is manageable for the average do-it-yourselfer. We chose to use the roll-and-tip painting method, and selected two-part polyurethanes from manufacturers that historically have done well in Practical Sailors topside paint durability tests: Interlux and Epifanes. On the port side, we applied Epifanes Poly-urethane No. 800 white thinned with Epifanes poly-urethane thinner, and on its starboard side and transom, we painted Interluxs Perfection Mediterranean White and used 2333N brushing reducer.

Paste Waxes Test Six-month Checkup

In February 2009, Practical Sailor tested a sampling of 10 paste waxes.After six months, two of these waxes clearly stood out for their continued ability to bead water and repel dirt. Collinite No. 885 Fleetwax and 3M Marine Ultra Performance Paste Wax retained the best gloss and water beading abilities. Mothers Cleaner and the Nu-Finish Paste performed well. Among the automative products that we included in the test, Turtle Wax F21, and Kit waxes stood out.

Six-Month Checkup: Long-Term Boat Wood Finish Exposure Test

Practical Sailor closes in on its search for the best teak oil, best marine varnish, and best synthetic wood finish this month. Testers check in on the 53 coated wood panels on our test rack, which have been enduring the elements for six months. Testers rated the panels for single-season gloss and color retention and coating integrity. The test products included dozens of one-part varnishes, two-part varnishes, synthetic wood finishes and stains, spar varnishes, wood sealants and teak oils from makers like Interlux, Pettit, Epifanes, Le Tonkinois, Minwax, Ace Hardware, Star brite, and West Marine. The long-term evaluation aims to find the best exterior wood finish based on overall ratings for ease of application, gloss integrity and appearance, and how the coating fares over time under real-world conditions. At the six-month mark, this report offers our single-season recommendations for finishing teak decks, cockpit trim, toerails, and other exterior wood surfaces.

Mailport: 05/09

In light of your recent letters on copper/epoxy antifouling bottom coatings, Id like to share my experience. Near the end of my Searunner trimaran boatbuilding project, I decided to apply a product known at the time as Copperpoxy. I applied the coating to all three hulls to about 20 mils thick, and then sanded this "orange peel" surface down to about 10 mils. I finished up with 220-grit sandpaper. In the end, it was beautiful. It was just like a perfectly smooth, new copper penny, and just a bit thicker than recommended. We started our cruising adventure in the foul waters of Beaufort, S.C. Very soon, I was doing a huge scrape job every week. The bottom was covered with grape-size barnacles. I noticed that the aft half of the main hull, the part with underwater metals, was fouling the worst. (I was changing zincs every week.) Two years later, in Pensacola, Fla., we decided to give up on this product and paint over it with Pettit Trinidad SR bottom paint. When doing the weeks-long prep for this painting, we could see that the skin of our epoxy/ply boat was electrically conductive and corroding all the way through in the entire area of the bonded shaft, strut, prop, gudgeons, and copper mast ground. We put on three coats of Trinidad, waited a few days, and splashed the boat. Within two weeks, the new paint had peeled off in the electrically active area. We re-hauled, stripped the paint in this area, and coated the problem Copperpoxy area with three coats of epoxy. After sanding and repainting, we set off for the Western Caribbean. Over the following six months, we noticed that even the epoxy would not stick to the Copperpoxy.