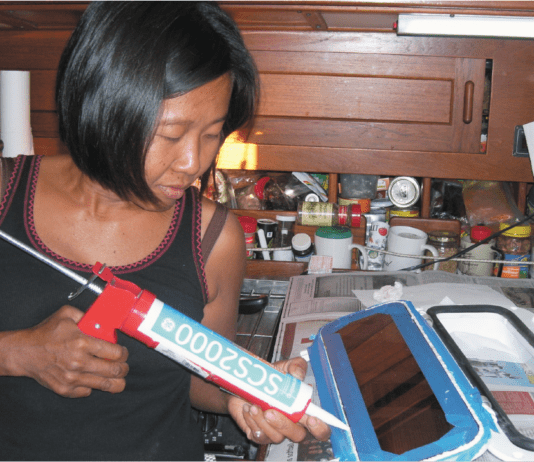

Stop That Leak!

The trick is to choose the right one. Some sealants get hard enough to sand or drill, and others stay supple. Some will stick to anything; others pull away from glass and certain plastics. Some will writhe and stretch as your boat "works." Others crack. And some, designed for household use, won't hold up in the harsh heat, cold, wind, and ultraviolet your boat is subject to. We recently took a look at a range of the most common types in the August 2010 issue. If you've got a teak deck to caulk, then our test of teak deck caulks can be found in the October 2008 issue.

Traction in Action: PS Tests DIY Nonskid Options

Boat owners looking to put some stick back into a slip-and-slide deck have a few options: apply a deck paint with a nonskid additive or glue sections of specialized nonskid mat to the deck. Choosing which type of nonskid is the right one for your boat makeover is a balancing act between aesthetic taste, traction needs, and budget. Practical Sailor tested 11 commercially available nonskid options that the average boat owner can easily apply: one paint with no filler media, five paints ready mixed with nonskid compounds, three nonskid additives that testers mixed with two-part topside paints, and two nonskid mats (one is self-adhesive, and one is glued on with an epoxy). All of the products can be applied to fiberglass, wood, or metal. Manufacturers included Pettit (Kop- Coat), Epifanes, AkzoNobel (Interlux and Awlgrip), West Marine, Pachena (KiwiGrip), Durabak, Tiflex (Treadmaster), and SeaDek. Using some creative bench tests, we evaluated how much traction, grip, and drag resistance each offered; we also rated how easy the products were to apply, how uniform the grit was, and how easy they were to clean.

Slippin’ and Slidin

A good DIY nonskid offers effective traction (obviously) and is easy to apply, easy to clean, durable, and gentle enough on knees and elbows that a foredeck monkey won’t leave blood stains behind. Testers focused on these criteria during bench testing, and when considering final ratings, we weighed the results according to their importance. For example, a product that had great grip but was hard to clean rated better overall than one that was easy to clean but offered no traction. This was a fairly close race, so we used a plus-minus system in the ratings (see accompanying Value Guide)—something we don’t often do—as every point mattered.

What’s In the Practical Sailor Toolbag?

Formerly the manager of a full-service boat yard, Practical Sailor Technical Editor Ralph Naranjo offers a survey of the tools he can’t live without. His toolbag is chocked full, and a peek inside finds saws, trimmers, planers, grinders, belt sanders, multi-tasking power tools, and drivers. His tool inventory—comprising top-of-the-line power tools and tried-and-proven devices, is one that enables him to handle most any boat project. If you’re looking to fill in you’re the gaps in your tool lineup or to stock your workshop, be sure to check out this special report.

Whats In the Practical Sailor Toolbag?

Formerly the manager of a full-service boat yard, Practical Sailor Technical Editor Ralph Naranjo offers a survey of the tools he can’t live without. His toolbag is chocked full, and a peek inside finds saws, trimmers, planers, grinders, belt sanders, multi-tasking power tools, and drivers. His tool inventory—comprising top-of-the-line power tools and tried-and-proven devices, is one that enables him to handle most any boat project. If you’re looking to fill in you’re the gaps in your tool lineup or to stock your workshop, be sure to check out this special report.

Is Titanium an Everyman Metal?

Titanium is of particular interest to sailors due to its resistance to galvanic corrosion. It has the highest strength-to-weight ratio of any metal and is non-magnetic. It is up to 20 times more scratch resistant than stainless steels. Practical Sailor contributor Patrick Childress takes an in-depth look at the metal and its use in the marine industry as his boat, a Valiant 40, is refitted with titanium chainplates and other rigging.

A Better Way to Mount Deck Hardware

Improperly mounted stanchion and pulpit bases are a major cause of gelcoat cracks in the deck radiating from the attached hardware. The cracks are usually the result of unequally stressed mounting fastenings or inadequate underdeck distribution of hardware loads. Frequently, a boat is received from the builder with local cracks already developed. Once the deck gets dirty enough, these minute cracks start to show up as tiny spider webs slightly darker than the surrounding deck gelcoat While repairing these cracks is a fairly difficult cosmetic fix, the underlying problem - poor mounting - is fairly easy to correct in most cases.

Sodablasting 101

When deciding on a process for clearing antifouling paint and coatings off the bottom of your boat, first define your goals and try to be as minimally invasive as possible. If your boat bottom needs more than a scrubbing but less than a full peel, sodablasting is a technique that will strip bottom paint but leave gelcoat intact. The unique softness of the calcium carbonate powder in sodablasting is effective, and the tented setup keeps the old coating contained. This report outlines the sodablasting process, calculates the cost in time and money, and compares its performance and cost-effectiveness to other bottom-stripping techniques we've tested.

Past Adventures with Chemical Strippers

Our foray into sodablasting follows years of testing several different ways to remove bottom paint. Although you can simply attack the bottom paint with a power sander (an 8-inch sander-polisher is probably the most common tool for this purpose), this approach is messy, back breaking, and can expose the do-it-yourselfer to various health hazards. It can also lead to dings and divots in the gelcoat caused by overzealous sanding. Many yards prohibit do-it-yourselfers from sanding antifouling, or offer specific guidelines on how it can be carried out-often prescribing a chemical stripper to help contain the paint residue.

The Best Marine Varnish: Exterior Wood Finish Tests

Testers applied dozens of exterior wood finishes (22 one-part varnishes, six two-part varnishes, 18 synthetics and satins/varnish alternatives, and eight teak oils and sealers) to small panels of bare solid teak and set them out to face the rigors of South Florida's weather. Two years later, our search continues for the ideal wood finish-relatively easy to apply, easy to maintain, lasts multiple seasons, and is affordable. Given that most wood coatings are rarely expected to last longer than two years in the marine environment-particularly in super-sunny locales-its no surprise that weve seen more significant changes in the coatings in the last six months than we had in previous checkups. With the exception of a few two-part products, the test coatings had lost their sparkle at the two-year mark, ratings slipped across the board, and weve come to accept that perhaps theres no Holy Grail of exterior wood finishes.