Unsticking Molds

Our boats are molded, heart and soul, from fiberglass resin. And while sailors will argue for hours over the best splice, multi-function display, or anchor, repairs or modification to the actual fiberglass structure are considered a black art. However, working with composite structures is not much more complicated than woodworking; it just requires a new skillset and a different bag of tricks.

Epoxy Fairing Compounds, Part One

Breathing life into an older fiberglass boat always entails more work than was expected, but for a person with the time, skill, and do-it-yourself inclination, it is often worth the extra effort. The DIY approach makes even more sense when the boats structural quality and big-ticket components meet the grade, and the skipper and crew are ready to tackle the cosmetic makeover. These fairing compounds are perfect for structural and cosmetic fiberglass repairs.

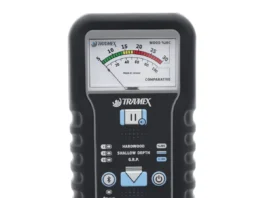

Testers Check Epoxy Sandability, Adhesion, and More

Testers evaluated sandability, resistance to sag, cure time, and adhesion using sample fiberglass panels with 3-by-3-inch test swatches. The fairing compounds were applied and cured in temperatures ranging from the low 60s to the mid-80s. Each test was repeated three times, and the results were averaged. The shaping test involved closely timed periods of even sanding using a block sander and new sheets of 80-grit sandpaper. Testers observed each materials tendency to clog the sandpaper, and measured the volume of accumulated dust after four minutes of sanding.

Careful Application Saves Your Sanding Arm

Epoxy fillers can be used to fix surface imperfections or for reshaping appendages like keels and rudders to make them more efficient. The smaller the surface imperfection, the less viscous the fairing compound should be. When filling deeper holes or voids, check the manufacturers recommended thickness per application. It may take two or more coats to achieve the necessary thickness. Applying filler too thickly can cause it to sag or will result in an incomplete cure.

Fairing the Keel(s)

One of the more popular uses for fairing compounds is for shaping underwater appendages like keels and rudders so they are more efficient. Adjusting the NACA (National Advisory Committee for Aeronautics) profile, or airfoil shape, of a fin keel or rudder can create more lift to enhance windward performance. Altering the trailing edge can yield similar improvements.

Through-bolting Fiberglass: An Inquiry into Failure Modes

How much load does a keel bolt or a winch through-bolt put on a hull or a deck? How thick should the laminate be at these bolt holes? How big of a backing plate is needed?

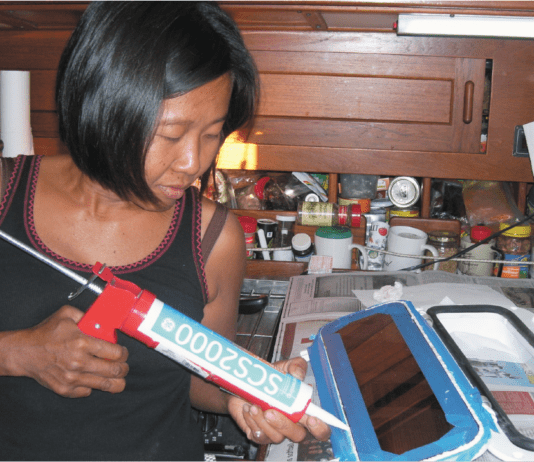

Adhesives Test

Once upon a time in Tasmania, a skipper faced a daunting task: install a three-bladed, folding propeller without hauling out the boat. The underwater job would require an adhesive to secure some of the bolts, but which adhesives that were already on board would work best under water? To find out, PS contributor Jonathan Neeves decided to run a little adhesives test of the three products he had on hand-all commonly found at chandlers worldwide under the same or a similar brand.

Bringing an Old Boat Trailer Back to Life

Over the years, weve stressed the importance of keeping a close eye on stainless-steel sailboat hardware and why pitting, crevice-corrosion, and galvanic action are the enemies. But we may have downplayed the need to be aware of how plain old ferrous-metal oxidation comes into the picture. Mild steel and high-carbon steel are even more prone to corrosion, and despite the fact that the oxidation is far easier to spot on these metals, this ticking timebomb somehow gets ignored.

Synthetic Decks vs. PS Testers

For this comparison of synthetic teak options, our first concern was ease of installation. The manufacturer typically carries out the hardest part-welding the panels together to achieve the correct dimensions. The ease of gluing our test panels to a simulated fiberglass deck was similar for all five test products. The difficulty of your own project will depend on how much work the manufacturer does in terms of measuring, assembling, and fitting the panels.

DIY Mast Boot

With a little imagination and some inexpensive materials, you can put together a leakproof mast boot in a few hours. 1. Roofing Rubber One reliable boot sealer is self-adhesive ethylene propylene diene monomer (EPDM), a common rubber-membrane roofing material. Sold at local building supply stores, the rubber is black in color and comes in a roll that is 5 inches wide. (Dont confuse it with ice and water shield, which is much thinner.) Peeling the plastic backing from the underside of the EPDM material exposes the sticky side. Arrange precut strips prior to permanent installation. We suggest using American-made products as the imported stuff doesn't adhere well to itself.