Painting Water Tanks

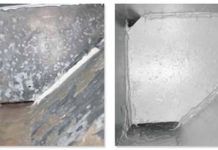

When it comes to onboard water tanks, we prefer stainless, fiberglass, and even roto-molded tanks (in that order) to aluminum ones. Aluminum tanks tend to pit and corrode over time, often needing to be replaced. The insides of the two 60-gallon aluminum water tanks in our 30-year-old Valiant 40 were more like a nasty moonscape than a drinking source. Their surfaces were pitted and rusted from what looked like a reaction to long-time use of chlorine.

Heavy-Duty Rubbing Compounds

Gelcoat provides a fiberglass boat with a hard, water-resistant protective shell. When new, its polished and waxed to a bright shine, but after a few years of facing the elements-especially damaging UV rays-gelcoat will begin to oxidize and turn into a dull, chalky film on the surface. There are a few ways to remedy an oxidation problem (see Tips & Techniques), but for this article, we focused on coarse and medium-coarse rubbing compounds, which can be buffed on to remove the chalky layer and fine scratches. The tests evaluated ease of use, ability to remove oxidation and scratches, and whether they left swirl marks; testers also considered price, availability, and eco-friendliness.

Tired Daysailer Hull Serves as Test Platform

Practical Sailor tested the compounds on the badly oxidized hull of a neglected 1974 ODay Javelin daysailer that has been stored uncovered in the Florida sun and salt air for years. Formerly the platform for gelcoat restorer and wax tests, the Javelins once dark-blue hull had degraded into a chalky, light blue mess.

Mailport: June 2013

How thick is too thick for the buildup of old layers of bottom paint? This question arises because I have just finished painting the bottom of my boat. Even though I diligently sought out potential flaking spots with my knife, while rolling on the paint (Pettit Ultima Eco), I would frequently get a mess caused by the paint flaking off. I have only owned this boat for three years, so I really do not know how many layers there are.

Indoor Sailboat Refinishing

I am restoring old fiberglass sailing club boats (Rhodes 19s) in a confined, heated space in winter, and I need to paint the topsides, decks, and bilges without poisoning the applicator. What do you suggest for a topside finish (white)? A repairable, long-lasting finish will be valued more than a high-gloss finish. Also, what do you suggest for the bottom paint? The boats will be in fresh water all summer; low environmental toxicity is a high priority.

Best Boat Soaps for Regular Washdowns

Sticking to a regular boat bath regimen not only keeps a boat looking good, but it also helps protect it from unnecessary, accelerated wear and tear. Practical Sailor tested a cross-section of 13 products-aerosol sprays, gels, powders, and liquids-advertised as either boat soaps or wash-n-waxes to find out which one was the best grime buster and which one left topside wax intact. The test lineup included products from well-known marine maintenance manufacturers-Star brite, Interlux, Woody Wax, Nautical Ease, 3M, Sudbury, and Marykate-as well as some familiar in the automotive and home cleaning industries-Mothers, Ecover, Eagle One, and K2r.

Topside-Paint Endurance Test 3-Year Checkup

Our topside-paint test panels have endured three full years of 24/7 exposure to the elements. Testers have regularly scrutinized the paint samples and rated the topside coatings on gloss retention, flow out, scratch resistance, and anti-oxidation ability. In this final round of evaluating, we also compared the panel results with the products real-world performances aboard our test boats over the last three-plus years. Top performers in the Practical Sailor tests included one-part urethane paints from Interlux, Epifanes, and Pettit, which all delivered handling convenience and a surprisingly long-lasting finish. The best two-part hull paints offered the most durability; picks in this group included coatings from Awlgrip, Interlux, and Sherwin-Williams, a good choice for the budget conscious boat owner.

Stuck Like Glue

Just about every sailboat owner has at some point mixed up a batch of epoxy to fill a hole, glue parts back together, or tackle an extensive project. Practical Sailor testers evaluated four marine epoxy resins based on their mechanical properties (strength, adhesion, hardness, and flexibility) and key handling attributes such as wet-out, sag, curing, and overall handling. We tested West 105 Epoxy Resin, MAS Flag Resin, Raka UV-inhibited epoxy, and Interlux’s Epiglass HT-9000.

Ralph’s Great Adventures in Laminating

Technical Editor Ralph Naranjo equates spare time with boat projects. His basement shop/test facility has spawned a wide range of boats, boards, and parts for bigger boats. The two latest are test platforms for long-term evaluation of the resins and materials looked at in this round of epoxy evaluation.

Ralphs Great Adventures in Laminating

Technical Editor Ralph Naranjo equates spare time with boat projects. His basement shop/test facility has spawned a wide range of boats, boards, and parts for bigger boats. The two latest are test platforms for long-term evaluation of the resins and materials looked at in this round of epoxy evaluation.