Old Salts Anti-chafe Solution

Being a team of diehard do-it-yourselfers, we decided to try our own hand at devising a workable solution to defeating line chafe. After fiddling with canvas, old fire hose, and even messing around with some Kevlar, we settled on leather—an old rigger’s standby. It proved to be rugged and remained unholed after a ride on the belt sander. The fabrication process was kids craft 101, and there was something quite seafaring about the result. …

Where Credit is Due: July 2011

Letters to Practical Sailor, June 2011. This month's letters cover subjects such as: Whale Pumps, Rigging and More!

Taming the Anchor Dancer

In any wind, our Jenneau 39i charges around an anchorage like a scalded cat, fetching up at the end of each tack (bow more than 90 degrees from the direction of the rode) with a noticeable jerk—even with a scope of more than 5:1. Comparing the behavior of other, more traditional boats in the same anchorage suggests that our centroid of windage is well forward, and that the cutaway foot and high-aspect keel offer limited resistance to the turn.

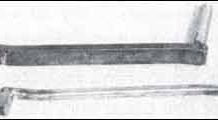

Design For: Winch Handles

Making spare winch handles is a simple job for a competent metal worker. This I discovered because our Norlin designed Scampi, Windhover, has eight winches, all of which were manufactured before the world standardized on the 11/6" winch handle lug size. Since Windhover's 9/16" size handles are difficult to obtain and impossible to find at discount I went to Frank "Red' Grobelch, a superb metalsmith/welder of Waukegan, Illinois with some ideas for making up some spares for me. I'm so pleased with the results that I'd recommend the project to any reader who is a competent metal worker or has a friend who is. Even if you can use and buy standard 11/16" size handles, your mental state when clumsy Uncle Fred drops a handle overboard will be far more buoyant if you know you can easily replace the lost handle in your own shop.

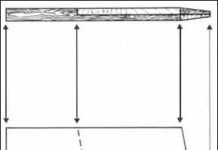

The Multifarious Mainsheet

The mainsail is a big part of the motive power of almost every sailboat. The art of mainsail control, however, is a relatively modern one. One tool that greatly facilitates mainsail control is the traveler. Traditionally, the mainsheet traveler was a heavy bronze or iron rod that allowed some control over the position of the boom relative to the centerline of the boat. In heavy air, the main could be eased down to leeward without easing the sheet, helping to keep the boat on her feet with the main still sheeted down. Compared to modern travelers this is a primitive system, but it can be made to work.

Metal Chafe Plates: Functional Remedy for Scrapes and Scratches

What do you do when the pin in the leg of your folding cabin table digs up the cabin sole? What do you do about the groove in the top of the teak toerail caused by your dock lines? What about the scuffs in the varnished bulkhead behind the companionway ladder? The answer is that you make chafe plates to solve all three problems. While chafe plates can be made out of almost any material — sheet PVC, thin stainless steel, aluminum — the most readily available and easily worked stuff is plain old brass. Brass can be purchased in many forms: sheet, solid round bar, pipe, tubing, and half oval, for example. It is quite cheap. If you have a local scrap metals dealer, you can buy enough scrap brass in various forms for $10 or less to keep you busy with a lifetime of projects. If there's no metal dealer at hand, most hobby shops carry substantial supplies of brass, although hobby shop brass tends to be thinner than what you want for most jobs.

Clear the Decks: Anchor Wells and Bow Rollers

Ever since some ancient mariner broke a toe tripping over the killick stowed in the bow of his curragh, sailors have sought to solve the mysteries of ground tackle stowage. The solutions have been endless, and as a rule compromises. A significant portion of the interior volume of a 19th century warship was given over to the storage of anchor rode. Even aboard modern boats, the search for the proper stowage of several anchors and chain, plus hundreds of feet of sometimes slimy nylon anchor line, is one that occupies both designers and boat owners. Two "modern inventions" — the anchor well, and the bow roller — have greatly eased many of the problems of ground tackle stowage. But even these developments vary greatly in quality and design, some creating more problems than they solve.

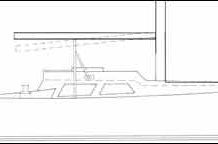

Taming the Wild Boom: Two Designs for a Gallows

A wildly flailing boom is one of the most dangerous objects aboard a sailboat. If you could completely control the boom at anchor and under power, and while raising, lowering, and reefing the sail you'd avoid worry, save energy and be much safer. For this reason, many serious cruising boats have traditionally carried permanent boom gallows. They usually take the form of metal pillars bridg ed across the top by a wooden cross member. Bolted to the deck at the aft end of the cockpit or on the aft deck itself, they serve several functions: holding the boom firmly when the sail is down; catching the boom easily as the sail is lowered; and, perhaps most importantly, keeping the boom steady during reefing operations.

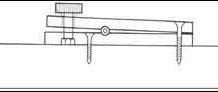

Design For: Stern Rail Mount Work Surface

For those who enjoy fishing or charcoal cooking, here's a design for a stern rail mount work surface useful for fish cleaning and meat cutting, and big enough to hold a hibachi when moored. I got the idea from yacht designer C.W. "Chuck" Paine, and Chuck got the idea from some Caribbean charter boats. You could also clamp a vise to the work surface and thus have a handy little work bench for onboard repairs and modifications. Mounted as it is on the stern rail, it is at a useful height, and offal and mess are easily cleared overboard. A hibachi used on the surface demands careful use, of course — as with any open flame on a boat — but it's about as far outboard a position as can be found. It's also a lot cheaper than those charcoal grills designed to be clamped to the stern rail.

A Homemade Tiller Tender

On my Catalina 22 I have a tiller tender which has served me well for many years — and it didn't cost a cent. On top of the tiller are two pieces of 3/8" x 3/4" hardwood about 5" long. The two pieces are drilled horizontally, at the joint line, about 2" from the end to accommodate a 3" length of split neoprene which has an inside diameter slightly less than the diameter of the braided line which runs to the coamings. Two holes drilled vertically near the ends are used to fasten the device to the tiller.