Photos by Patrick Childress

When rigs fail, it is often a spectacular event, precipitated by the sudden breakage of a rig component-a wire, a terminal, or a chainplate, for instance. Because this so often comes as a surprise, and because it has been known to happen even to conscientious sailors who regularly inspect their rigging, it is natural to assume that at least some of the causes must be hard to detect; they must be, to some extent, hidden. And this is true. Ish.

That is, there are lots of places in a rig where corrosion can hide, places that require some effort to get at. We will be looking at some of those places, but as you will see, the word hidden can have more than one meaning.

Photos by Brion Toss

1 Physically hidden

This section of the mast was covered by a stainless gooseneck fitting. There was no isolating material between the fitting and the mast. The resulting galvanic corrosion was severe, and the corrosions byproduct-aluminum oxide-expanded so powerfully that it compressed the mast wall, causing it to buckle inward and tear.

This is the kind of thing that we usually think of when we talk about hidden causes of rig failure: something physically covered that escapes our otherwise vigilant notice. But what really hid this was not knowing that expansion inevitably accompanies corrosion. In addition, removing the plate for inspection would involve removing the boom-a major inconvenience.

2 Hidden by poor instructions

This is the inside of a Sta-Lok fitting. One of the strong points of these and similar fittings, like Hayns Hi-Mods and Norsemans, is that they can be disassembled for inspection. Had the owners taken advantage of this feature, they could have stopped the corrosion before it reached the stage shown here, by injecting a sufficient amount of sealant (like 3Ms 4000) to fill the inside of the terminal.

This prevents the intrusion of both air and water, so that the terminal will not suffer from either crevice corrosion, oxidation, or chloride corrosion. The assembly instructions for this type of terminal are typically incomplete, in at least five languages. One manufacturer told me that the company does not want to make the instructions more complete because they fear people would think the terminals were too difficult to use. Among the instuctions shortfalls is-you guessed it-the amount and type of sealant to be used. As a direct result, this type of terminal suffers from a needlessly high rate of corrosion failure, especially in the tropics.

3 Hidden by sloth

Terminal wires are supposed to look like this, not like those in photo No. 2. Above, the cover yarns are formed over the wedge, instead of being bent over and mashed against the body of the terminal. Had the owners of the atrocious terminal (No. 2, left) taken the time to disassemble the terminal, they would have discovered, not only the corrosion, but that whoever assembled it did a truly horrid job.

4 Hidden underwater

Another classic example of a hidden cause of rig failure: This bobstay stem fitting is riddled with crevice corrosion, and is suffering from weld decay, a form of galvanic corrosion. This fitting was under water most of the time, making it inconvenient to get to and inspect.

Similar failures are often experienced with chainplates. In fact, chainplate failure is the single most common cause of dismastings. The problem is that the corrosion nearly always occurs in the deck, or against the outside of the hull, where the metal cannot be inspected without removing the chainplate.

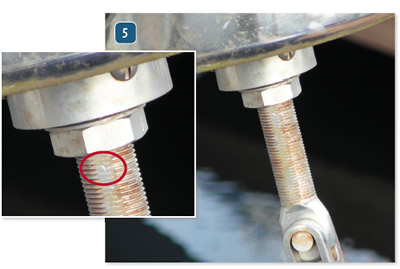

5 Hidden in the owners manual

Here is the bottom stud on an old-model Harken jib furler. It looks a bit weathered, but there are no problems, either showing or hidden … except that the stamped circle (red oval) is Harkens way of marking the maximum allowable thread extension of this stud fitting. When the furler was new, that circle was painted bright red. This boat has been sailing with the stud extended well past the do not exceed limit, meaning that there are too few threads engaged to handle high loads safely. It hasn’t stripped and pulled out yet, but it has been too close to the edge, considering that it is keeping the mast out of the cockpit. If this fitting were to fail, the hidden cause would have been hidden in the manual. Read the manual!

6 hidden by geometry (part 1)

In this catamaran martingale installation, the angle of the stay is not lined up with the attachment points of the hardware (long red line). This results in torque (arrows).

7 hidden by geometry (part 2)

The red circles show where torque has caused cracking in the crossbeam welds. The hidden cause here is geometry, hiding in plain sight. Its abstract, but it has real-world effects.

8 Hidden in The (Nearly) Impossible hiding place

This is a top view of the martingale stay turnbuckle, visible in the preceding two photographs (Nos. 6 & 7). Notice that it is fully closed. What are the odds that this stay will have reached a perfect state of tune exactly when the turnbuckle runs out of threads?

Theres no corrosion here, no foul leads, no damage to the turnbuckle, but the odds make it extremely likely that the stay is either too slack, or too tight. If the former, the beam will flex upward; if the latter, it will flex down. In either case, one can expect deformation-related damage. And sure enough, on this boat, there were cracked welds at the base of the martingale A-frame strut, in the center of the crossbeam. The hidden factor here was the red-flag anomaly of the closed turnbuckle. Components don’t need to be in danger of failing in order to cause a rig failure.

9 Hidden in the shadow

Even if you do take the trouble to go aloft for an inspection, problems wont always be evident. This is a shroud tang, held in place by a throughbolt. Everything looks solid, but what is that shadow of unpainted aluminum (circled) above the tang? As it happens, that shadow is where the tang used to be; the through-bolt doesn’t have enough bearing surface on the mast wall, and the downward pull of the shroud is slowly tearing a slot into the mast. This results in a slack rig in the short term, and possibly a collapsed mast in the long term. A bushing or other reinforcement will prevent this.

10 Hidden Aloft

Pictured here is a Norseman fitting on a big charter catamaran. Note the diagonal crack right across the top. This was hidden because it was up the mast a ways, and once again, it was inconvenient to inspect. If someone hadnt gone up there for an inspection-and happened to look closely-a dismasting would have been the result. Hidden a little deeper was the fact that the manufacturer of this fitting used a steel alloy that is not compatible with the forging process that formed the eye. The fact that manufacturers do things like this is one of the reasons why regular aloft inspections are so important.

11 Hidden by ignorance

Another hidden cause, and no, its not that broken toggle. Theres no way to miss that. You don’t need a trip aloft, or a manual, or a knowledge of trigonometry, or the energy to disassemble something, in order to find the broken toggle, an imminently deadly problem. You just have to pay attention.

Context: This is a boat on which a rig failure resulted in the death of a passenger not very long before this photo was taken. You would think that the crew of this particular boat would be obsessive about rig inspections, would be so hyper-aware of the potential consequences of a rig failure that they would be unable to miss something like this.

Sure, we wouldnt let this happen. But before we get to feeling too smug, we need to bear in mind that most hidden problems are not hidden behind physical obstructions; they are hidden behind the walls of our ignorance. If we don’t comprehend how energy flows through a rig, don’t know the properties and characteristics of the materials that the rig comprises, it can be very hard to find things before they fail. We will walk right by scary problems, not because we don’t care, but because we don’t know, or notice. If you want to know what the worst cause of rig failure is, I can tell you: It is us boat owners.

12 Hidden in plain sight

The owners of this boat got a lovely new Rocna anchor, and it wasnt going to fit on the stem. (This is a common challenge; these are popular anchors, but they do take up a lot of room.) The resulting platform installation was very nicely done-stout, good welds, polished-but there are at least two glaring, dangerous problems hiding in plain sight here. Can you spot them?

Heres one: There is no bobstay. Moving the jibstay out into space creates a lever arm (blue line), with the unopposed vertical component of the jibstays pull (red line) now focused on the forwardmost fastener holding the platform to the deck. The dotted white line shows where a bobstay might lead.

But remember: There are at least two serious problems here. Can you spot the other one? Well set aside the advisability of that chain keeper for the anchor. The second problem is another design detail that could tear off the anchor roller.

If you think you know what it is, send your answer to author and rigger Brion Toss , who has offered a free copy of his upcoming book, Rig Your Boat, to a person (selected randomly) who gets it right. Send your answer to Toss at [email protected].