Chandlery: February 2015

Laser rescue flares like those offered by Greatland Laser (see PS February 2004, March 2011, and September 2013 online) have long been marketed as a way to attract the attention of potential rescuers. One issue associated with their use has been accurate aiming to get the rescuers attention. The new Picatinny Mount Laser Flare Holder, made by North American Laser, aims to take the guesswork out of, well, aiming.

40 Years of Breaking Boat Gear

Practical Sailors 40th anniversary came and went last year without hoopla. We talked a while about marking the event with a stroll down memory lane, or a photo-essay tracing our evolution from a courier-type bulletin to our current incarnation, or a best of collection celebrating our most talked-about tests. They were all nice ideas, but at age 40, your limitations become clearer, and routines that a twenty-something might chafe at offer a measure of peace-why break them? Daily ruts feel more like grooves.

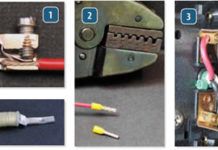

Out, Out Brief Wiring Terminals!

Eurostrips, Euroblocks, set-screw terminations-whatever you want to call them-they are here to stay. Many companies supply set-screw terminations as part of electronics installations, solar controllers, inverter/chargers, navigation lights, or even engine gauge panels. These set screws, if not protected by a pressure plate or a wire terminal, can cause damage to the wire stranding and eventually lead to failure. Attention to the details should always be top on the list when dealing with Euroblocks or any set-screw termination that bears directly onto the wire strands.

New Anchoring Rules on Horizon in Florida

So far, no one at the Florida Fish and Wildlife Conservation Commission has returned my phone calls, so Im left trying to imagine what might have compelled the commission to release a public survey on anchoring restrictions during the days bracketing Thanksgiving week, with very little (if any) advance notice, as far as I can tell.

Searching for Spray Shine

Is there a quick, easy way to get a glossy shine on the deck and topsides between the grueling wax-and-buff efforts? To find out, testers launched a search for affordable spray waxes-liquid waxes designed for speedy touchups rather than full-tilt compounding-and-waxing jobs. We specifically sought out spray-on products that offer a glossy finish and some surface protection and that are applied after rubbing compounds, fillers, waxes, and polishes.

Taking the Other Way Home

Our 38-foot catamaran, Josepheline, was built by Lightwave Yachts near Brisbane, Australia. Josepheline draws 3 feet, 6 inches and has a 22-foot beam. It is a fairly conventional design: mini fin keels, two forward queen berths under the bridgedeck, a double berth aft to starboard, and a decent sized shower and head located aft in the port hull. Shes stood the test of time-and distance. Weve cruised about 35,000 nautical miles aboard Josepheline.

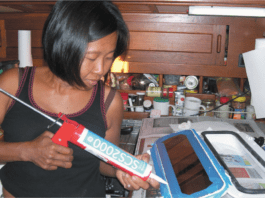

Painting Water Tanks

When it comes to onboard water tanks, we prefer stainless, fiberglass, and even roto-molded tanks (in that order) to aluminum ones. Aluminum tanks tend to pit and corrode over time, often needing to be replaced. The insides of the two 60-gallon aluminum water tanks in our 30-year-old Valiant 40 were more like a nasty moonscape than a drinking source. Their surfaces were pitted and rusted from what looked like a reaction to long-time use of chlorine.

Will Your Tanks Be Clean Next Spring?

When contributor Drew Frye commissioned his familys PDQ 32 catamaran six years ago, his daughter asked, What are these pink lumps in the sink, Dad? The toilet bowl was even more spectacular, a science project in a dozen hues of pink, green, yellow, and black. The boat had been winterized for some time, down in south Chesapeake Bay, where winters are mild and many boaters and don't take freezing seriously.

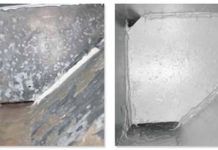

Repairing Worn Gelcoat

Regarding your blog post on restoring gelcoat (posted online March 18, 2014): Ive seen many similar articles over the years directed toward refinishing topsides. However, Ive seen no discussion about restoring decks. I have an 18-year-old boat, and Im beginning to see pinholes in the deck gelcoat, particularly on edges and curves where I suspect the gelcoat is thinner. Im curious what the experts would recommend.

Testers Check Growth in the Lab and on the Boat

When testing a chemicals toxicity and its ability to biodegrade, a common procedure is to dilute each target chemical at various ratios of interest, and then to inoculate each with an acclimated microbiological seed. For our test, the seed was developed by filling a five-gallon bucket with several gallons of water and a weak mixture (two percent total glycol content) of all of the winterizing agents to be tested.