Whats In the Practical Sailor Toolbag?

Formerly the manager of a full-service boat yard, Practical Sailor Technical Editor Ralph Naranjo offers a survey of the tools he can’t live without. His toolbag is chocked full, and a peek inside finds saws, trimmers, planers, grinders, belt sanders, multi-tasking power tools, and drivers. His tool inventory—comprising top-of-the-line power tools and tried-and-proven devices, is one that enables him to handle most any boat project. If you’re looking to fill in you’re the gaps in your tool lineup or to stock your workshop, be sure to check out this special report.

Bottom Paint Stripping

Although we’ve tackled our share of varnish with a heat gun and scraper, we’ve never used them to strip bottom paint. The obvious concerns would be marring the gelcoat and the noxious fumes created by heating paint solvents and active ingredients. Our first choice for removing antifouling would be sodablasting (PS, October 2011), but as that’s not an option for you, we’d consider chemical stripping (PS, April 2008 and March 2009), wet-sanding, or vacuum sanding.

Mailport: January 2012

Letters to Practical Sailor, January 2012. This month's letters cover subjects such as: Flare disposal, Chainplate failures, MOB Pole storage and more!

Where Credit is Due: January 2012

Letters to Practical Sailor, January 2012. This month's letters cover subjects such as: Shurflo, Ronstan, and Keen Footwear

Is Titanium an Everyman Metal?

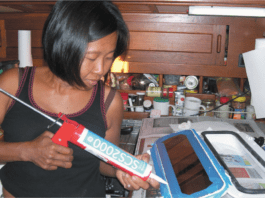

Titanium is of particular interest to sailors due to its resistance to galvanic corrosion. It has the highest strength-to-weight ratio of any metal and is non-magnetic. It is up to 20 times more scratch resistant than stainless steels. Practical Sailor contributor Patrick Childress takes an in-depth look at the metal and its use in the marine industry as his boat, a Valiant 40, is refitted with titanium chainplates and other rigging.

Mailport: December 2011

Letters to Practical Sailor, December 2011. This month's letters cover subjects such as: boatleather, pump plumbing, dinghy wheels, and more!

Where Credit is Due: December 2011

Letters to Practical Sailor, December 2011. This month's letters cover subjects such as: ScanMarine, Midland Management, and more!

Mailport: November 2011

Letters to Practical Sailor, November 2011. This month's letters cover subjects such as: Eastport Pram Fan, Coppercoat, Lightning strikes and More!

November 2011 Product Updates

Canada Metal Pacific (CMP) of Vancouver has acquired New Zealand-based Rocna Anchors, a company embroiled in a controversy over anchor quality after production had shifted from New Zealand to China. According to CMP, Rocna anchors will continue to be produced in China, but at a different plant in Ningbao, China—one that is wholly owned by Canada Metals Pacific. Rocna anchors made in Shanghai were recently the subject of a “specification notice” issued by marine retailer West Marine, which was reported on in the September 2011 Practical Sailor. The notice informed Rocna anchor owners that some Shanghai-made Rocnas did not meet the company’s original advertised specifications.

Where Credit is Due: November 2011

Letters to Practical Sailor, November 2011. This month's letters cover subjects such as: Standard Horizon, Defender Industries and Weems & Plath