Mailport: 05/08

I am writing to add some additional comments on the article "Navigation, a Lost Art?" in the January 2008 issue. The aim of your article was on target, and I agree with the points given concerning the limits of technology. The various devices mentioned in the article fall into two broad categories: those such as GPS chartplotters that help the sailor to maintain the spatial awareness that lies at the heart of navigation and those that help the sailor to maintain a better lookout. Radar actually lies in both categories. A third category includes devices used to communicate, but these are outside the scope of the article. A fundamental issue is whether the use of GPS chartplotters is of greater help in maintaining spatial awareness than paper charts.I think not. On our boat, which has a GPS chartplotter, we find that the small screen gives us a restricted view of our situation. In order to get a broader view, we must change the scale, but that causes information such as ledges, buoys and water depths to be omitted, in order to avoid excessive screen clutter. The result is that we keep the plotter on a large scale in order to keep buoys, etc. on the screen. It is akin to peering at the world through a mousehole. Our chartplotter also has the option of a radar overlay, but the optimal choice of radar range to detect other boats does not always coincide with the optimal scale of the plotter needed for navigation.

Fuel Filtering Systems

I am the new owner of a 1979 Tayana Vancouver 42 with a Volvo D2-55B diesel engine installed in 2004. Fuel is held in two 80-gallon fiberglass tanks and filtered via a Racor 500 utilizing No. 2010 filters. I use 2-micron filters and Biobor JF Anti-Fungal additive. Despite fuel scrubbings, I continue to have to change primary fuel filters with each fueling. I have been told that I don't need as fine a filter as the 2-micron, but I don't want to risk increased maintenance of the diesel. What do you recommend?

Mailport: 04/08

I loved the article about the 30-footers from the 70s (February 2008). The subtitle was especially appropriate: from the "age of plaid interiors." (I can hear Bachman Turner Overdrive now!) Its great to read, and dream, about the new boats, but they usually carry the price tag of a house. Im sure youll hear the "What about the ….?" So I would say, what about the Islander 30? It seems to fit your criteria. I own an Islander 28, which feels to me like a 30 with its 10-foot beam. It has the basic criteria you mentioned, and which I wanted: standing headroom (510"), a real head, galley, berths for four or five, and inboard diesel power. My Islander is a 1977, and I paid $9,000 for it. One thing I really like about it is its construction. It is also nice to sail, with a balanced helm and the ability to take San Francisco Bays 25-knot winds without much fuss. Its sturdy, attractive, good interior, a good value, and theres enough of them to get info and help for.

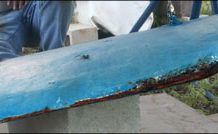

Rust Converters

Chances are good that anyone who owns or has worked on a vessel equipped with an iron keel has at one point or another come across products that, "turn rust back into sound metal," or make other similar and often impossible-sounding claims. The question is: Do they work, and is this the best approach for an iron keel? Make no mistake about it, iron is cheap, and thats the primary reason for its use where keels and centerboards are concerned. Lead is nearly always preferred, at least for ballast keels, because its denser and weighs more for a given volume than iron, and it doesn't corrode. Some vessels use bronze as a centerboard material, and while its not as dense as iron, all sailors know it does not corrode. Irons use as a ballast keel or centerboard material comes at a price, a price that is paid over the life of the vessel by its owner or owners. If the iron is not properly isolated from the water in which the vessel floats, it rusts prodigiously. Some studies have shown that an inch of iron will create 16 inches of shale rust. The insidious nature of the way in which iron rusts is often its, or the vessel owners, undoing. Unlike steel, which tends to slough off as it rusts, iron often retains its shape, rusting from the inside out. Thus, it may look sound, however, a sharp blow from a hammer may release huge chunks of material. This type of decay is referred to as graphitization because graphite residue is all that remains.

Mailport: 03/08

Hurricane Charlie, the second of three hurricanes to hit Daytona Beach, Fla., in 2004, found my 1982 Lafitte 44 at an anchorage on the Intracoastal Waterway, just south of Daytonas three bridges. My anchors held. But a series of calamitous events resulted in Twilight breaking free, then washing ashore at the foot of a riverfront apartment complex. She was on a sandy beach, but her bow overhung a low concrete rip-rap seawall that had been reinforced with steel rebar. As the boat swung about in the storm surf, she demolished about 20 feet of the sea wall, knocking down the rip-rap and bending the reinforcing steel. There was some abrasion to the boats hull but, more than anything else, the damage was cosmetic. Her hull was not penetrated.

Mailport: 02/08

I read that you are going to review the Lavac head in the future. I have one on my Bristol Channel Cutter 28 and love it. A couple of things: Though the makers claim that the Lavac uses as little as 3 pints per flush, I use over 3 quarts. The Lavac manual suggests 13 to 16 strokes, which exceeds 1 gallon per flush. It will be interesting to see your results. Also, it is critical that the Henderson pump be mounted no less than 45 degrees from vertical. Otherwise, the simplicity and reliability of the Lavac is terrific. It has managed some seriously challenging flushes without flinching.

When Keel, Stub Part Ways

I have a 1980 Albin Cumulous with an iron keel. The keel has recently been cleaned, primed, and painted, and is holding up well. However, the seam between the keel and the keel stub is opening up. The keel bolts are not leaking. The last time this seam opened, I squeezed in some 3M 101 polysulfide sealant and that seemed to work. Is there a better sealant that I should be using?

Mailport: 01/08

Thank you for your excellent article on heat-related failures of nylon line ("Nylon Rope Endurance Test," December 2007). When a boat winds up on the beach after a storm, its easy to look at the frayed ends of a mooring line and announce that it had chafed. Your study reinforced what our claims experience has been with nylon mooring and anchor lines in storms: Failures are more likely to be caused by heat than abrasion. Our claims experience at BoatU.S. has been that mooring or anchor lines are most likely to fail between the foredeck cleats and chocks. A line that is compressed at the chock under storm load loses up to half its strength. At the same time the line is being compressed, it is also being stretched back and forth across the chock, which creates tremendous heat. The farther the cleat is from the chock, the more the line will stretch and generate heat.

Well Grounded

We recently installed an aluminum fuel tank on our 1984 Endeavour 40. During installation, we took several steps to avoid galvanic corrosion, including fixing gaskets at contact points, providing airspace around the tank, and connecting it to the boats grounding system. We considered connecting one of those "zinc fish" to the grounding system, hung over the side at the dock. Could I fasten a small zinc to the tanks grounding tab? Or attach zincs to each tank and through-hull?

Mailport: 12/07

Regarding your query about solidly built boats, I have owned (and had built) my 1981 Mariner 47, a Ted Brewer design built in E. Rochester, N.H. She is a heavily constructed fiberglass boat (about 36,000 pounds displacement) that has seen in excess of 150,000 miles of cruising under my command. During that time, I struck the side of the Cape Cod canal (solid rock) under full power because of an autopilot malfunction while I was singlehanding. Ive also struck a ledge in Portsmouth, N.H., at 12 knots (power plus current) at night when I missed an unlighted mark (again singlehanding). Ive also struck rocks in Marblehead, off Cuttyhunk, and near Rockport, Mass. None of these fiascos resulted in more than minor damage to the solid-lead keel. A similar disaster I witnessed to a more lightly built boat (a Kalik 44) drove the keel up through the hull, fracturing the bulkheads and resulting in a total loss of the boat.