A great many sailors believe a splice intended for high loads is not complete until it is fitted with a thimble. Undoubtedly, a thick layer of steel provides the ultimate in abrasion resistance when attaching to a rusty, galvanized mooring shackle. And the thimble also increases the turning radius, which more evenly distributes the load among the fibers that make up the weave. But are thimbles best, and is a thimble best or even required in all circumstances? We are especially interested in strength.

Photos by Drew Frye

A light thimble can distort under high load. Cheap wire thimbles often have sharp edges, and even well-polished examples can open the weave or chafe at strands, or seriously damage a splice if they shift.

At the heart of the problem is stretch. Nylon double braid rope stretches about 12 percent for every 20 percent of breaking strength; 3-strand rope stretches about 15 percent and climbing ropes stretch about 18 percent. Because each leg of the eye carries only half of the load, the stretch at 20 percent of breaking strength should be only 6 percent, but we must add to that some construction stretch, since it takes time for a splice to settle in. As a result of all the stretch, even factory-installed thimbles become loose at high load.

Even when a thimble is very well-fitted and tightly seized-as good and any we have seen-and stretched to the normal working load (10 percent breaking strength), it becomes quite loose. Any side load or binding could allow the thimble to shift its position. We were sent images of a bridle on a Jordan Series Drogue (a drag device used to slow the boat in a storm), and the bridle was severely chafed by a thimble that shifted. Had it failed, the consequences would have been serious. A closed thimble or a webbing sleeve is a safer choices for this application. We’ve seen similar near failures resulting from open-style thimbles in mooring applications as well.

Thimbles come in many types, including wire-rope thimbles, closed, or sailmakers thimbles, and captive-rope thimbles of many designs.

A thimble isn’t the only means of guarding against chafe. The load-bearing surfaces of the spliced eye can also be protected with a secondary cover or tubular-webbing chafe guard (See Fiber Coating Protection Plan, September 2015). Which is better for typical applications on a racing keelboat or cruiser?

Photos by Drew Frye

Some general considerations our testers explored:

Wear. A mooring line around a rusty shackle is a perfect case for a thimble. Abrasion is aggressive, and a nice thick layer of steel offers the best protection. But what about eyes attached to polished stainless shackles? Unless they are under extreme load and simultaneously sawing back-and-forth across the shackle pin, ring, or other load-bearing attachment point, there will be virtually no apparent wear.

Chafe can vary greatly depending on use. The topping lift on one of our test boats attached to a relatively sharp-edged shackle, so we used a webbing sleeve for padding instead of a thimble. Even without a sleeve it should last for a long time. The previous topping lift showed very little wear after for 15 years without any sleeve or thimble.

Strength by Type

Any rope is weakened when loaded around a small radius. The fibers on the outside carry more load than those on the inside, which may actually be slack, doing no work at all. This effect can be mitigated by changing the ratio of the rope diameter (D) to the diameter of the shackle pin (d) or other attachment point.

For determining block size, D/d ratios of at least 8 are recommended to cope with the loads and the greater potential for chafe. But depending on the application, the loads, and type of line used, the D/d ratio for an eye-splice can be as little as 1:1 without risking failure. The following discussion of D/d ratios applies only to spliced eyes in a splice, in which each leg carries only 50 percent of the load.

Wire rope. Wire rope is the extreme case, requiring a 20:1 D/d ratio. Wire does not stretch, and is subject to fatigue if repeatedly bent, and thus a thimble is required to increase the radius. Since wire rope does not stretch much, and because the cable is also steel, the thimble should stay put and would do little harm if an edge did chafe the cable.

Nylon. Fibers that stretch (nylon) do not suffer extreme strength reduction around a tight radius, because the fibers naturally share the load better. When the ratio of the rope diameter (D) to diameter of the pin (d) or shackle is 1:1, nylon is the strongest of all common rope constructions.

When the D:d ratio = 1 with these ropes, the strength of the eye is undiminished. It is true that each leg of the eye is weakened 50 percent, but because each leg only carries 50 percent of the load, the strength of the eye is undiminished, and the splice is usually the first to fail.

In the case of nylon, some increase in diameter may be desirable for lines that are routinely loaded over their working load limit (9 percent of breaking strength). Factory-added spinning lubricants help resist chafe but don’t last. This protection be partially restored in used ropes by treating them with certain water repellent coatings (see Winter Sailing Tips for Die-Hards, Practical Sailor, December 2016).

High molecular polyethylene (HMPE): Slippery HMPE fibers (such as Dyneema) share the load better, since they can easily slip over each other. Like nylon, when the D:d ratio = 1, the strength of the eye is undiminished. Because the line diameter and the pin diameter are generally about equal strength in applications that use Dyneema, no thimble is required. Heat-set Dyneema, used for standing rigging, is a special case, and should have a thimble or ring.

Polyester: What about polyester, so common in running rigging? In most cases it is oversized for stretch and hand, and thus will be working so far below its working load limit (20 percent of breaking strength) it is irrelevant.

Type of weave: Plaited weaves are generally better than three-strand or double braids, since they flatten out across the bearing surface, more effectively spreading the load on all the fibers.

The bottom line is that during our entire break-testing program of Dyneema, nylon, and polyester eye splices, we never saw a failure over the pin (see Sewn Splices Follow Up, PS June 2016). We saw failures within the splice, at the end of the splice, in the throat, and even in the center of the rope, but never at the pin.

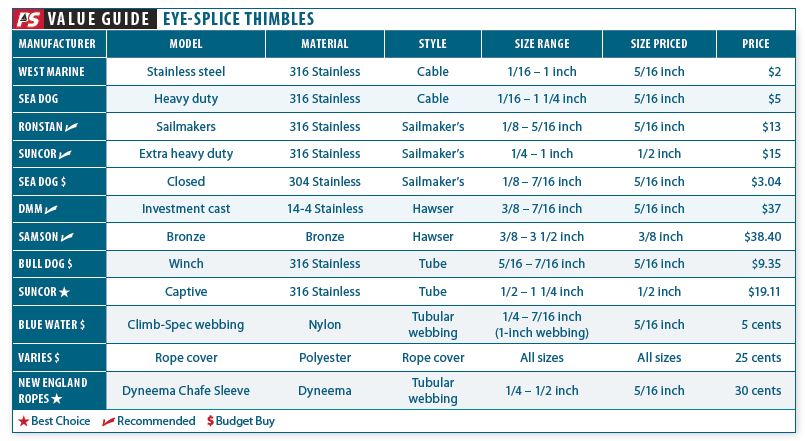

Thimble Types

Thimbles come in many types, including wire-rope thimbles, closed or sailmakers thimbles, and captive thimbles of many designs.

Wire Rope Thimbles

Traditional and often cheap, lighter-duty open thimbles distort under load and have sharp edges. Even strong, well-polished versions can shift and damage rope. Occasionally the splices are tightly lashed in place, but this is like treating the symptoms rather than the cause.

West Marine Stainless Thimble

The sample we examined was expensive, but it was also poorly finished.

Bottom line: Recommended for wire rope only.

Seadog Heavy Duty

Slightly heavier construction than the West Marine thimble, but marginal polishing.

Bottom Line: Not our first choice. For wire rope only.

Sailmakers Thimbles

Either welded or cast in an elliptical shape, these present no sharp edges that can damage a rope or sail. However, they do increase the throat angle (the angle formed by the two legs of the spliced eye) slightly and can fall out if poorly fitted or highly strained.

A wider throat angle can also weaken a splice. In addition, sailmakers thimbles can bend when strained to the limit by Dyneema, becoming loose.

Ronstan

This is a nicely formed, welded thimble. These occasionally bent under extreme load (Dyneema only) but never failed.

Bottom Line: Recommended by many years of use.

Seadog Closed

Cast from 304 stainless steel, these appear well-made and should be very durable.

Bottom Line: Recommended.

Extra Heavy Duty, Suncor

Cast from 304 stainless steel, these are well polished and strong.

Bottom line: Recommended.

Captive Thimbles

Traditionally used on large mooring hawsers because of the challenges in fitting other thimble types to large stiff lines, these have become popular with Dyneema winch cables. Their ability to maintain strength even after being distorted is a great asset.

Bull Dog Winch Thimbles

Marketed to the RV crowd for Dyneema winch cables, this 316 stainless steel tube thimble is strong and secure. Once again, a bit of poking outside the marine market finds what we need for less.

Bottom line: Budget Buy in a closed thimble.

Suncor Captive

This is another tube thimble, strong and secure.

Bottom Line: Recommended for larger sizes.

DMM Investment Cast

This is a 316 stainless steel hawser-style thimble of very high quality.

Bottom Line: Recommended

Samson Ropes Bronze Thimble

This very traditional-looking bronze hawser-style thimble is sure to outlast the boat.

Bottom line: Just the thing for a traditional boat … at a price.

Webbing Chafe Guards

In many cases, this may be all the protection you need. The thick nylon tubular webbing pads over sharp corners, increases the D/d ratio slightly, and easily manages any abrasion that can occur between a polished pin and the rope.

It also has advantages that no other thimble design can match: they cannot slip out of position, damage the rope, or scratch the deck. They are lighter, cost practically nothing, install in seconds, and are suitable for knotted loops as well. Perhaps the only downsides are that they are still unfamiliar to many sailors, and the appearance is decidedly non-traditional.

Bluewater climb-spec

Made from very densely woven nylon, this well-proven chafe gear lasts at least 10 times longer than a typical polyester rope cover. For additional wear, coat with Maxijacket.

Bottom Line: This is our Budget Buy for most applications, and probably the Best Choice in most cases. It has been used extensively on one of our test boats for more than 30 years.

Polyester Cover (various brands)

Often covers are available, either from high modulus line covers that have been stripped by racers, or salvaged sections of lines that have seen little wear (the portion of a halyard that lived inside the mast is often very good). A larger size can be slid over the eye. A cover is particularly useful for knotted lines, where it can also reinforce the knot.

Bottom line: Recommended when webbing is too bulky.

NE Ropes Dyneema Sleeve

This thin but incredibly durable covering proved virtually wear-proof in prior testing (UV, Chafe Protection, March 2105 Practical Sailor ). The only down side is the ends are difficult to melt, and tucking it in is impractical in a splice. Thus, a neat job requires advanced skills.

Bottom Line: The Best Choice in soft thimbles.

Conclusions

We’re not fond of wire rope thimbles for tough jobs. Although they have a long, generally successful history, we’ve seen too many cases where the thimble itself did serious damage. A sailmakers thimble is one answer. There are no sharp edges and they do not distort under high load.

For very high load, larger lines, and even knotted eyes, captive thimbles offer a more expensive but dependable solution. That would be our choice for a mooring pendant, combination rope-chain rode (splicing direct to the chain is even better), Jordan Series Drogue, or sea anchor. But for most running rigging jobs, either no thimble or a webbing chafe sleeve is the best answer.

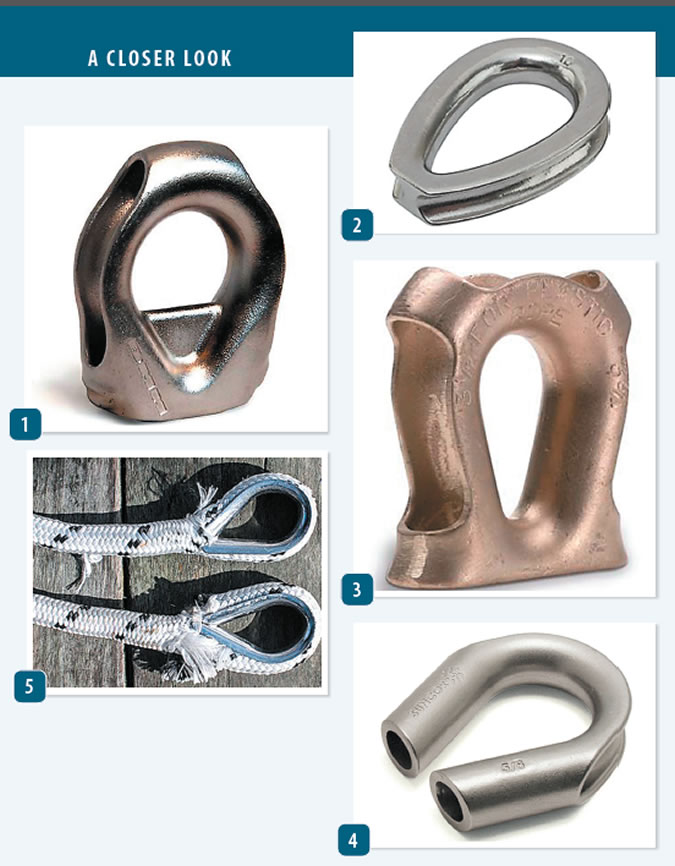

There are dozens of types of thimbles designed for specific purposes. The most common type is the simple open thimble, perhaps the most poorly suited for applications under heavy loads, because of the risk of chafe.

Closed sailmaker thimbles can reduce chafe, but some designs that are more round than oval can open up the throat of the splice, which can weaken it.

1. DMM’s investment cast thimble has a high lip and smooth exit at splice.

2.The closed Seadog Line 316 stainless steel thimble is thicker and has less sharp edges than open style thimbles.

3. Sampson’s investment cast bronze hawser thimble was the most expensive in our comparison$38.

4. Suncor’s 3/8-inch stainless steel tube thimble offers excellent chafe protection where needed and will not easily become loose or dislodged.

5. These images taken from the bridle for a Jordan Series Drogue device show the chafe that can happen when an ordinary open thimble is put under load.

Interesting that you found that dyneema can handle a 1:1 bend ratio without loss of strength. I’d always assumed that knots (assuming same-diameter rope) would result in no worse than a 1:1 bend ratio, but I’ve seen tests showing that that causes dyneema to lose 70–75% of its strength when knotted. Any idea why the discrepancy?

Thanks for a great review of thimbles. I’m considering a thimble on my secondary anchor rode on SV Cadence. Going with a thimble instead of a direct splice to chain, so I can free the line from the chain for easier stowage and to free the rode for multiple purposes. After reading your article, I know to stay away from the open thimble, so I’m going to buy a Seadog.