In our recent investigation into anchor shackles, Anchor Shackles, the $15 Insurance Policy (PS August 2015 online), we were aware that our sampling lacked statistical validity. Testing one shackle sampled at random and finding that it meets specification offers some reassurance, but no guarantee. Likewise, a single failure in such a narrow test does not necessarily indict the whole product line. After reading this report, you should also look at our more recent update, which addresses some concerns raised by manufacturers as well as their responses, with their own follow-up testing.

In this report, we continue our investigation into shackles, re-testing one shackle that fell below the makers specifications, Canada Metal Pacifics black-pin Titan shackle, and testing for the first time a widely used shackle from West Marine. We also offer our initial findings on two stainless-steel shackles: the Tecni-lift 316 bow shackle and a no-name stainless-steel shackle marked Hong Kong, which is representative of the many generic stainless shackles youll find in hardware stores and some chandleries.

We also tested an Omega-type shackle that had been treated with the Armorgalv process and fitted with a G100 pin that also was treated with Armorgalv. As we described in our recent report Armorgalv vs. Hot-dipped (PS March 2015 online), the Armorgalv coating process protects high-ferrous, quench-and-tempered steel in sea water, but it doesn’t reduce the metals strength like hot-dip galvanizing can.

While we’d like to test dozens of shackles at once, this would prove too unwieldy, so our shackle testing is ongoing, and there will be future published updates.

For further details on each of the products were reporting on here, as well as those from the last test that are featured in the accompanying Value Guides, be sure to read the August 2015 shackles report. We also encourage you to read our other previous articles on shackles, which you can find by searching for shackles at www.practical-sailor.com.

Sizing Shackles

The maximum size of your anchor shackle is limited by the size of your anchor-chain links. When you are choosing shackles, the surest way to ensure that you are getting the right size is to take a few connected links of chain with you to the chandlery and make sure the shackle pin actually fits the hole. The most common types of anchor chain BBB, G30, G43, and metric chain all have varying chain-link hole sizes for ostensibly the same diameter (thickness) wire. Shackles of the same nominal size also vary; even the shackle-pin diameter varies. Take nothing at face value-test it out first. When buying chain in bulk, some vendors allow you to order chain with oversized links at each end, making it easier fit the larger shackle pins; this is a good option for those who prefer G43 chain.

The other critical factor is strength. Ideally, the shackle should be stronger than the anchor chain. However, achieving this becomes difficult once you start moving into chains rated G43 or higher. The 3/8-inch shackles we look at here should fit common 5/16-inch proof-tested chain stamped G30 (7,600 lbs. nominal breaking strength) or G43 chain (11,400 lbs. nominal breaking strength). For more on chain standards and breaking strengths, including those for metric chains, see Making Sense of Chain Standards.

However, safety margin becomes even smaller when the effects of side-loading are taken into account.

When the shackle pin or body is loaded from an angle, the shackle body can be forced open, causing the pin to break or fall out. This is the most common failure we have seen in our tests-even though our test involved a straight pull. According to warnings posted by several manufacturers, a 45-degree side load can reduce the shackles rated strength by 25 percent, and a 90-degree load can reduce it by 50 percent.

Fortunately, high quality shackles have a safety factor of between 4:1 to 6:1, meaning the actual failure point is four to six times greater than the rated working load; so, in theory, a good shackle is capable of handling side loads.

How do we identify a good shackle? In the U.S., shackle standards are spelled out in RR-C-271F, Federal Specification for Chains and Attachments, Carbon and Alloy Steel. In this report, we are focusing mostly on Class 2 (screw-pin) shackles that meet or exceed RR-C-271F IVA Grade B Class 2 specifications.

Other classes will meet these working load requirements- Class 3 shackles, secured with bolt, nut and cotter-pin instead of a screw pin, for example-but the essential nomenclature here, is Grade B. This grade has twice the strength of the more common Grade A shackle. (Makes no sense to us either, but B is Better.)

How We Tested

All of our break testing was carried out at Robertsons (www.lifting.com.au), a commercial rigging supplier and approved testing facility near Newcastle, Australia. We followed a typical protocol for shackle testing: pulling the shackle to yield and then to breaking point, with data recorded continuously. Results were portrayed graphically, showing load versus extension, and ultimate tensile stress at failure.

What We Found

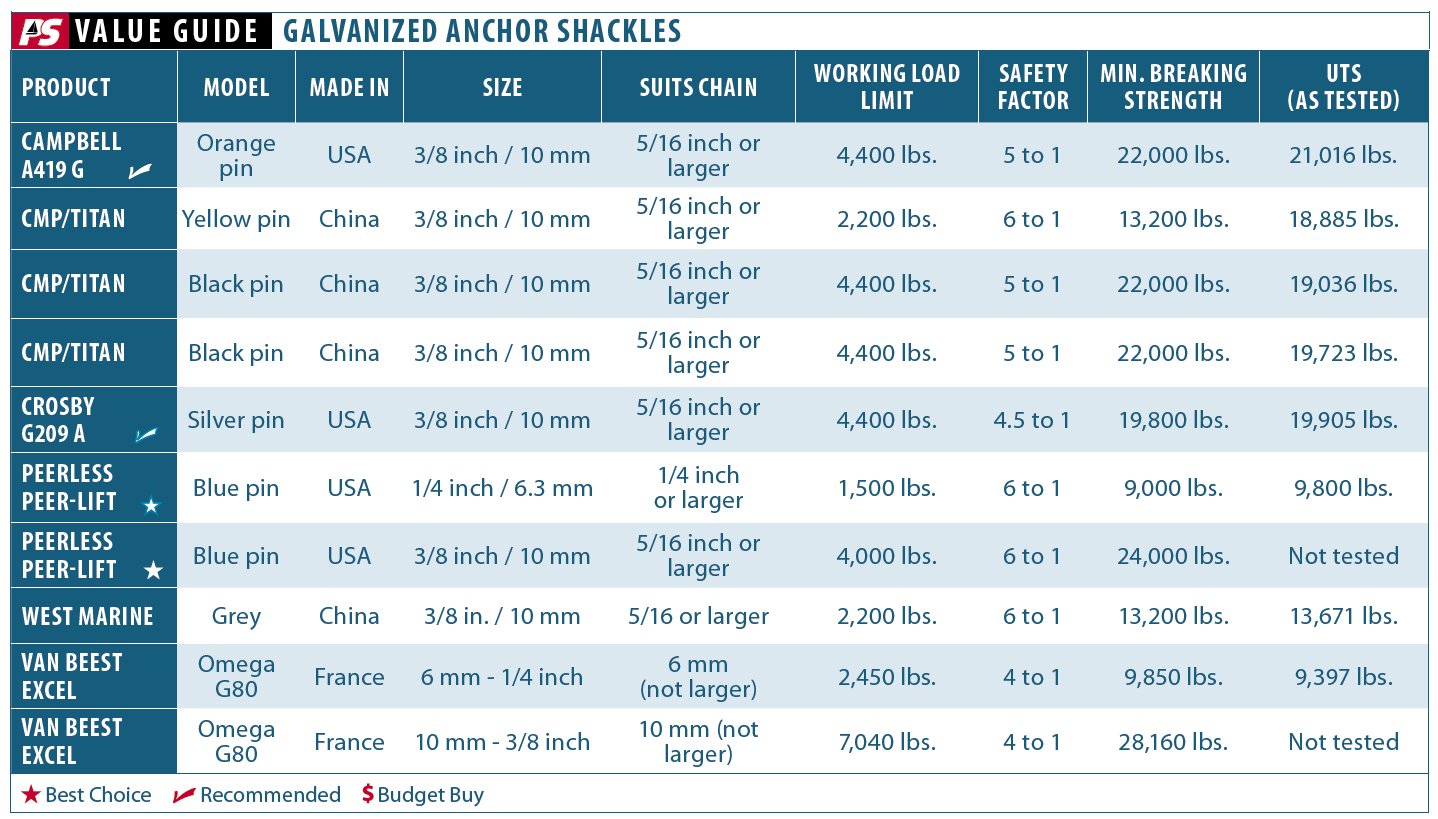

Our findings, illustrated in the accompanying tables, are summarized below. To quickly review, in our 2015 tests, shackles from Peerless, Crosby, Campbell (all Grade B shackles), and CMP (a yellow pin, Grade A type shackle) all met their own specifications, but our test of CMPs black-pin shackle (Grade B type shackle) fell about 10 percent short of CMPs own specification.

Failure of all five of these shackles was in the shackle pins. The pins sheared at the thread (the thinnest point), where the pin entered the threaded eye. There was some distortion of the shackle body, but not significant, and some of this distortion might have been caused after the pin sheared. We saw a similar pattern of failure in this round of tests. For comparative purposes, the results of the previous test are shown in the Value Guides, along with the current test results.

Canada Metals Pacific

The second Canada Metals Pacific (CMP) black-pin shackle-bought six months after we tested the first shackle-failed in exactly the same way at a very similar load: 19,723 pounds. CMPs specifications state a minimum breaking strength of 22,000 pounds, so this shackle also underperformed CMPs own specs by about 10 percent. However, it was close enough to Grade B specs (20,000 lbs. breaking strength) to be within a reasonable margin for error.

Although CMPs black-pin shackles have a higher rated working load limit and minimum breaking strength (4,400 pounds / 22,000 pounds) than its yellow-pin shackles (2,200 pounds / 13,200 pounds), we could find no other difference beside the pin color. Both failed at approximately the same loads (within 10 percent). This means that the yellow-pin shackle is much stronger than its rating, and the black-pin is slightly weaker.

Bottom line: Canada Metals Pacific is looking into our findings and commissioning independent testing. We look forward to learning what its experts find and will be carrying out further testing on our own.

West Marine

The second galvanized shackle we tested from West Marine was marked WLL 1t CHINA 3/8. It was purchased at a West Marine in West Islip, N.Y., on Long Island. Breaking at 13,671 pounds, the shackle met West Marines specification of a maximum breaking strength of 12,000 pounds, but it demonstrated severe extension and distortion prior to breaking. The shackle bow broke, and the threads on the shackle pin stripped, allowing the pin to pull out of the eye. Both the bow and the clevis pin were distorted.

The shackles behavior under load was unlike any others in the test. It began distorting almost immediately as load was applied. Given what we know about anchor loads (see Anchor Testing and Rode Loads, PS May 2012 online), it seemed likely that this distortion could occur during use. Grade B shackles from CMP, Peerlift, Campbell, and Crosby-showed no measurable permanent distortion until loads exceeded 50 percent of breaking strength.

Bottom line: We do not recommend using the galvanized West Marine shackle in any high-load application, and we especially advise against using one in an anchor rode.

Stainless Steel

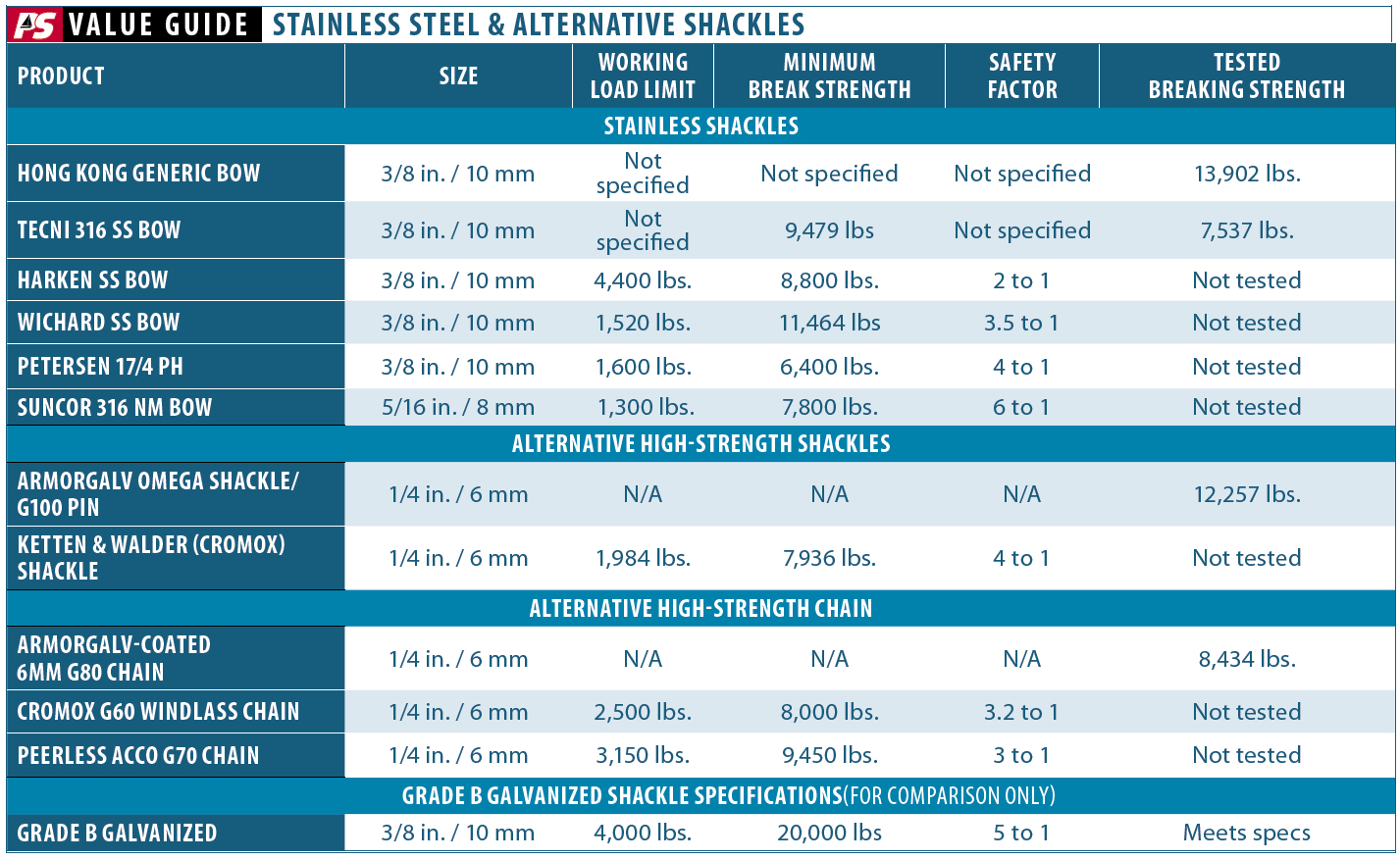

Stainless steel is a poor material choice for anchor shackles, in our view, and our recent test supported this. If, for some inexplicable reason, you insist on using a stainless shackle in your anchor rode, keep in mind that sizes and safety factors vary widely, so comparing working load limits can be misleading. For example, Harkens stainless-steel bow shackle has a safety factor of 2:1, while Petersens safety factor is 6:1. The range for galvanized shackles, by comparison, is between 4:1 and 6:1.

The stainless shackles all showed a high degree of elongation, and we are concerned that shackles with such distortion would be more susceptible to side loading than the high-tensile, galvanized shackles. Although we did not test side loading on any of the shackles, it seems obvious that once a shackle begins to elongate under side loading, strain is concentrated at the shackle pin and threads, increasing the likelihood of failure there.

Given the low yield point of 316 stainless-steel shackles, we expected them to deform more easily than the galvanized shackles. The effect it had on the shackle pins was severe; the threads and the recessed head of our sample shackle became so elongated that it pulled right through. Out of curiosity, we also tested some 316 stainless chain, which again distorted almost immediately as load was applied.

Bottom line: Given the behavior of these two samples, we simply can’t recommend 316 chain or shackles anywhere in the anchor rode assembly.

Tecni Bow Shackle

The Tecni 10-millimeter recessed head bow shackle is sold with a minimum break strength of 9,479 pounds, but it failed after severe distortion at only 7,537 pounds. The bow was converted to an elongated U; the shackle pin was severely distorted. The pins recessed head-designed to make it easier to roll over a bow roller, we presume-pulled right out of its eye, and the threaded end of the pin almost pulled out of the eye and then sheared. The Tecni, like the West Marine shackle, started to deform almost as soon as load was applied.

Bottom line: This shackle was a disappointment in testing. It is possible that it would deform in heavy use and would need to be cut off.

Generic 316 Shackle

The generic 3/8-inch, 316 stainless-steel bow shackle that our tester bought in the back streets of Hong Kong fared marginally better than the Tecni. It achieved a breaking strength of 13,902 pounds (commendable for an unbranded shackle of this size), but like the other stainless hardware we tested, it started to deform almost immediately as load was applied. It eventually failed when the shackle pin sheared at the thread/eye interface.

Bottom line: It bears repeating: Dont use a stainless-steel shackle in the anchor rode, particularly one of unknown origins.

Alternative Shackles

Part of the aim of this project is to uncover marine-ready shackles that might be paired with the small-diameter, high-strength chains rated at G70, G80, or higher. These chains, commonly used in lifting applications, are attractive to some cruisers who like the idea of a chain rode, but not the added weight it brings. The logic behind this quest raises several questions (see Pencil Thin Anchor Rode, PS June 2016), but in the interest of science-and requests from our readers-we press on.

One of the most promising shackle designs for this purpose was the G80 Omega-link that is commonly used in lifting. We sourced ours from Van Beest. Because these arent available galvanized, we had to galvanize the link ourselves, using the Armorgalv process. It fared well enough in the first test to inspire more experimentation.

This time, to make the link even stronger, we used a G100 pin. It was the sort of backyard project that makes manufacturers of lifting equipment cringe, but perhaps someone will introduce a factory solution that passes muster with risk management.

Our Armorgalv-treated, G80 Omega link with G100 pin showed very little distortion, just as we had found in previous test. The mouth of the Omega opened slightly, and the shackle pin sheared. The ultimate breaking load of this hybrid unit was much higher than the chain it was paired with-so you could say it exceeded our expectations.

Bottom line: For the boat owner who is intent on downsizing to a super-strong, lightweight chain, it appears that an Omega link is a viable option. This intermediate link provides a means of attaching a large, high-strength shackle to a G43 (or even a smaller G70 or G80) chain, without adding a weak link-so to speak. The downside is that until someone comes out with a marine-ready version, the owner would need to arrange galvanizing. The Armorgalv process is the only one weve tested and found suitable for these grade materials.

Conclusions

All of our testing was conducted with straight-line pulls, using curved load-bearing surfaces concentrated in the center of the shackle pin. In real life, anchor shackles are loaded unevenly-concentrated at one end of the pin, for example-and the slots in anchor shanks are often flat and sharp, creating point loads on the shackle. Modern anchors can set so well that they don’t align with the chain when the wind changes direction, creating an uneven load on the shackle. In other words, a shackle that deforms easily during our simple test will be much more vulnerable in the real world.

Admittedly, our test with just a few samples of each shackle is not a statistically valid representation of the thousands shipped each year, but because our test was such a cakewalk in comparison to the real world, we think the results are cause for concern.

We have now tested two CMP black-pin shackles that have failed below CMPs rated load. The shackle failed at loads close to that of its competitors, but we see no reason to condone using this shackle when others that live up to their billing are available. There are many possible explanations as to why any product does not meet a manufacturers rating. Because rated strength is such an essential part of a shackles value, consumers deserve to get an accurate number for rated strength.

Even more concerning is the West Marine shackle. This is shackle has all the appearance of a good product. It is embossed with the load rating and sold through a reputable merchant. But if we respect the warnings about side-loading (a reduction of 50-percent strength, or more), this shackle is unfit for service in the anchor rode, in our opinion. We contacted West Marine with our findings. At presstime, West Marine was working with Fasco, the shackle supplier, to conduct further testing. We look forward to their findings.

To their credit, West Marine has been very supportive of our testing program. They have also been very responsive when weve raised red flags. When PS discovered that Rocna (under its former manufacturer, not CMP) was misrepresenting the materials used in its anchor shank, West Marine was the only major retailer to set up an exchange program. We expect that the company again will do the right thing. In our opinion, this shackle should not be marketed as a ground-tackle accessory until other independent testing proves it is up to the task.

The take away bit of wisdom here is that if you are looking for an anchor shackles, specify Grade B shackles from Peerless (Peerlift, Grade B), Crosby (G209 A), and Campbell (Grade B). These shackles are all proof tested by their manufacturers, and we’ve found no reason not to have faith in them. (CMP also proof tests its shackles, so we were somewhat surprised at our findings.) Although we did not test the Peerless shackle in the 3/8-inch size, other Peerless shackles have performed well in our tests. We will be answering the question of strength once and for all soon, when we put it on the test bench.

For lower-load situations, CMPs yellow-pin Titan shackles are fine-they performed well over specification-but not so well as to recommend them over Peerless, Crosby, and Campbell Grade B shackles for anything but moderate-load service above the waterline.

For those who are dead-set on converting to G70 chain, the Omega shackles look promising. Until it is manufacturer-approved, though, we can’t endorse its use for such a critical application.

If you have a shackle story to share-good or bad-let us know at [email protected].

The above 3/8-inch shackles should fit common 5/16-inch proof-tested chain stamped G30 (7,600 lbs. nominal breaking strength) or G43 chain (11,400 lbs. nominal breaking strength). For more on chain standards and breaking strengths, including those for metric chains, see Making Sense of Chain Standards, which accompanies the online version of this article.

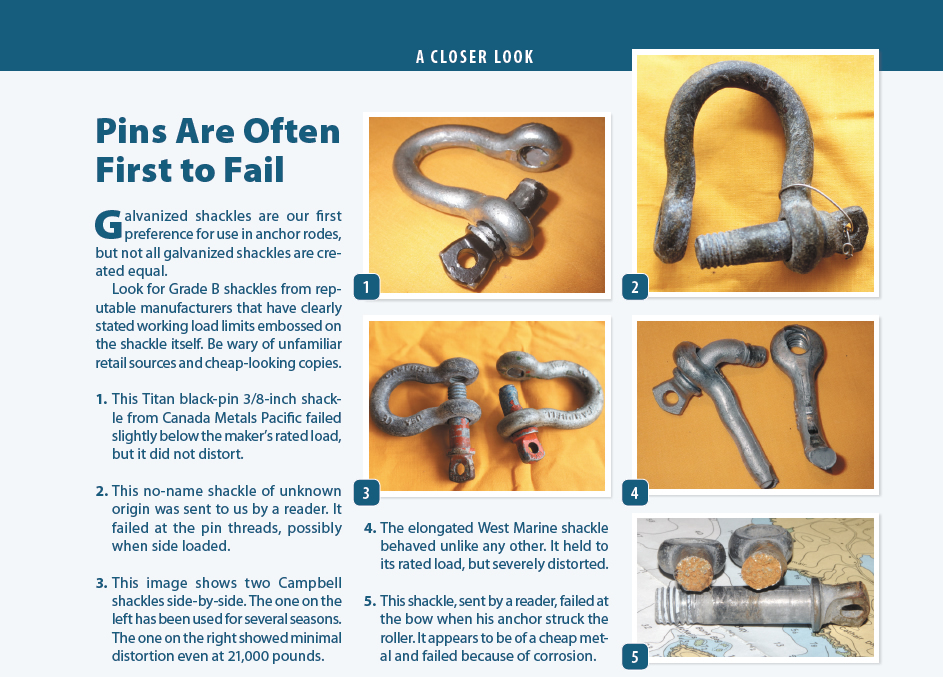

Galvanized shackles are our first preference for use in anchor rodes, but not all galvanized shackles are created equal.

Look for Grade B shackles from reputable manufacturers that have clearly stated working load limits embossed on the shackle itself. Be wary of unfamiliar retail sources and cheap-looking copies.

1. This Titan black-pin 3/8-inch shackle from Canada Metals Pacific failed slightly below the maker’s rated load, but it did not distort.

2. This no-name shackle of unknown origin was sent to us by a reader. It failed at the pin threads, possibly when side loaded.

3. This image shows two Campbell shackles side-by-side. The one on the left has been used for several seasons. The one on the right showed minimal distortion even at 21,000 pounds.

4. The elongated West Marine shackle behaved unlike any other. It held to its rated load, but severely distorted.

5. This shackle, sent by a reader, failed at the bow when his anchor struck the roller. It appears to be of a cheap metal and failed because of corrosion.

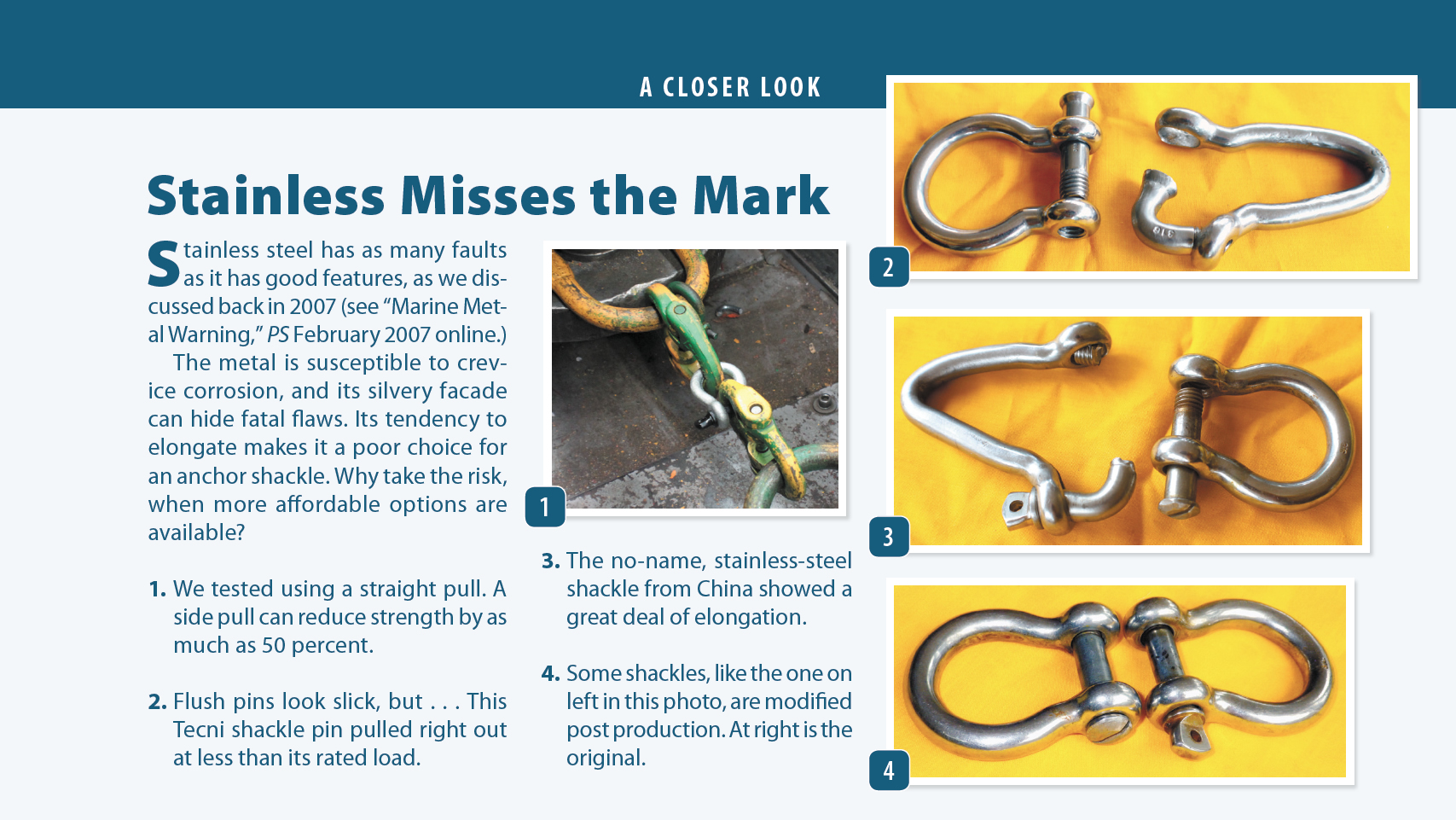

Stainless steel has as many faults as it has good features, as we discussed back in 2007 (see “Marine Metal Warning,” PS February 2007 online.)

The metal is susceptible to crevice corrosion, and its silvery facade can hide fatal flaws. Its tendency to elongate makes it a poor choice for an anchor shackle. Why take the risk, when more affordable options are available?

1. We tested using a straight pull. A side pull can reduce strength by as much as 50 percent.

2. Flush pins look slick, but . . . This Tecni shackle pin pulled right out at less than its rated load.

3. The no-name, stainless-steel shackle from China showed a great deal of elongation.

4. Some shackles, like the one on left in this photo, are modified post production. At right is the original.