We’re always amazed how a sailor can spend months agonizing and wringing their hands over which anchor to purchase, and then, when they finally shell out $700 or much more for the anchor, they’ll attach it to a shackle that has no business being on a boat.

We’ve plowed through the topic of shackles (mainsail shackles; snap shackles), but we haven’t looked specifically at anchor shackles. Choosing a properly sized, high-quality shackle is important, but it’s also essential to be familiar with proper use.

For this comparison, we focused on galvanized shackles of proven styles, from established manufacturers. We also explored some of the alternatives to conventional galvanized bow shackles.

Anchor Shackle Basics

The typical anchor shackle is a galvanized bow shackle, with the bow (not the pin) passing through the oversized slot in the anchor shank. In some cases, a D shackle is used, but only when there is no slot in the shank. Examples of slot-less anchors include the CQR, Guardian and the Manson Ray.

By definition, the shackle must have an eye small enough to fit through the slot, and must have a shackle pin small enough to fit into the link in the chain. Even though it’s restricted by size, it should be stronger than the chain.

Finding shackles strong enough to fit high-tensile G43 chain outside America is difficult. And it is impossible to find a shackle that will match G70 chain. If you find a shackle to fit the link and anchor slot, it is either not made of galvanized steel and/or it has never been tested in a marine environment. For a more detailed discussion of chain grades, see Looking Into the High-Test Myth.

Construction and Security

Reputable galvanized bow shackles today are forged and made from high-strength alloy steel. Bow anchor shackles also have a narrow mouth, to compensate for the high loads at the pin. The narrow mouth restricts the thickness of the shank to which they will fit. Shackles come in a wide range of designs, but the most basic design is a simple bow of alloyed steel with a threaded clevis pin.

It is essential that shackle pins are secured. Commonly, screw pins are secured with mousing wire. You can also use a thread sealant like Loctite (numbers 243, 242, 222, 638, 680, and 609). Loctite is fairly reliable, but you should plan to regularly re-apply the sealant.

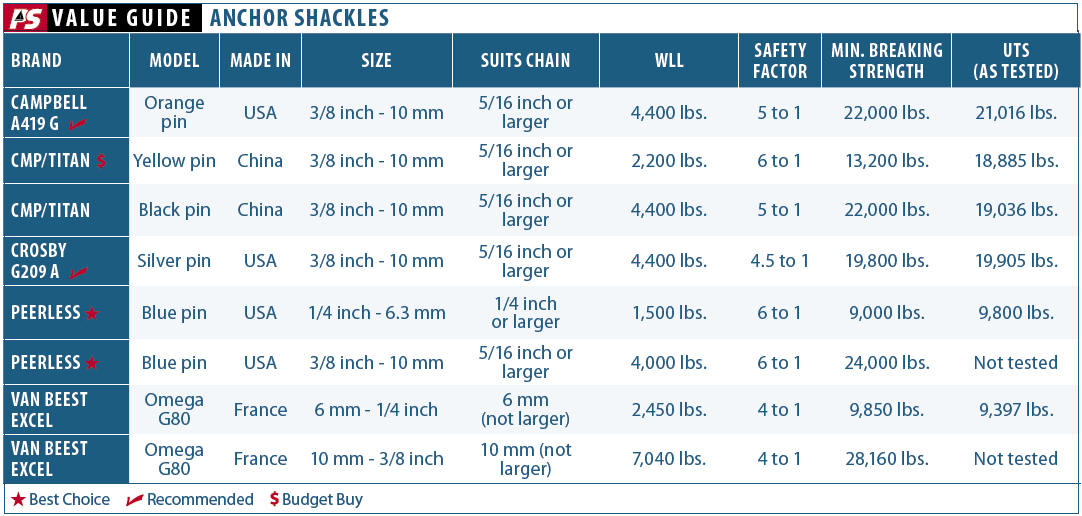

What We Tested

Shackles are generally available in two grades: Grade A and the stronger Grade B. In the 3/8-in. shackle size, Grade B shackles have a working load limit of two tons; the Grade A working load limit (WLL) is half of that. For this report, we focused on the higher-load Grade B shackles. There are a large number of established manufacturers of galvanized bow shackles, but we limited our evaluation to Peerless, Campbell, Crosby, and Canada Metals Pacific (CMP)/Titan as these are the established names in the industry. We did not look at cheap shackles of unknown origins, or those that bore the scent of counterfeiting, a known problem in this industry.

Crosby

Crosby, now part of Kito Crosby (and soon to be under Columbus McKinnon), is arguably the most familiar U.S. shackle manufacturer. Based in Tulsa, Oklahoma, the company has been making shackles for over seven decades and has a design for every conceivable application and environment. Crosby makes other components for lifting, but among sailors, it is best known for its shackles. They have an enviable reputation for quality, and their G-209A shackles—forged from alloy steel, quench-and-tempered, and galvanized— have become the standard anchor shackle in the U.S.

Campbell

Campbell is a part of Apex Tools and is another significant player in the anchor-chain industry. The company has a range of galvanized bow shackles ideal for anchor rode.

Van Beest

Van Beest is a Dutch manufacturer that has been supplying components to the lifting industry for almost a century. It is well known across Europe and parts of Asia for its green pin shackles, but it also supplies G8 and G10 lifting components under the Excel brand—rebranded to Green Pin in 2018—from its French factory.

We did not have access to Van Beest shackles for testing, but it is worth noting that the makers’ 10-mm green pin bow shackle has an oversized 11-mm pin with a working load limit of 1,000 kg (2,204 lb.).

Canada Metals Pacific

Canada Metals Pacific is best known in the marine industry for its range of Martyr-brand sacrificial anodes and as licensee for the Rocna anchor. It also licenses the Vulcan anchor, and makes a range of anchor chain in China under their Titan brand. CMP also introduced a range of Titan shackles.

Others

There are several other well-known international companies that supply the global market in lifting equipment and make shackles: Columbus MacKinnon, Gunnebo, Rud, Pewag, etc. These are reputable sources, but because of time constraints, and because these brands are not so widely marketed to boaters, we did not include them in this test.

Shackle Alternatives

There are alternatives to shackles. Some regard hammerlock chain connectors as an option, but we have some concern about the abrasion and corrosion resistance of the very thin, high-tensile pin that holds the assembly together. Boats in New Zealand often use an Omega link. The Italian chain-maker Maggi supplies a galvanized Omega link to be used with its high-tensile G70 chains, but we were not able to acquire one for testing.

As an experiment, we took some 6-mm G80 Omega connectors made in France by Van Beest and had them coated using the Armorgalv process (see PS March 2015 online). These also were included in this test. Another option, again from the lifting industry, are G80 pear shackles. These are widely used in New Zealand, and we hope to test some in the future.

Our investigation into alternative designs was prompted by a common question: How does one connect a smaller-diameter, higher-tensile chain (G70 is commonly cited) to an appropriately sized anchor without sacrificing strength at the shackle. For a number of reasons, we strongly prefer conventional G30 or G43 chain over G70. (See Looking into the High-test Myth, PS June 2014 online.)

What We Found

Failure Modes and Testing Conditions

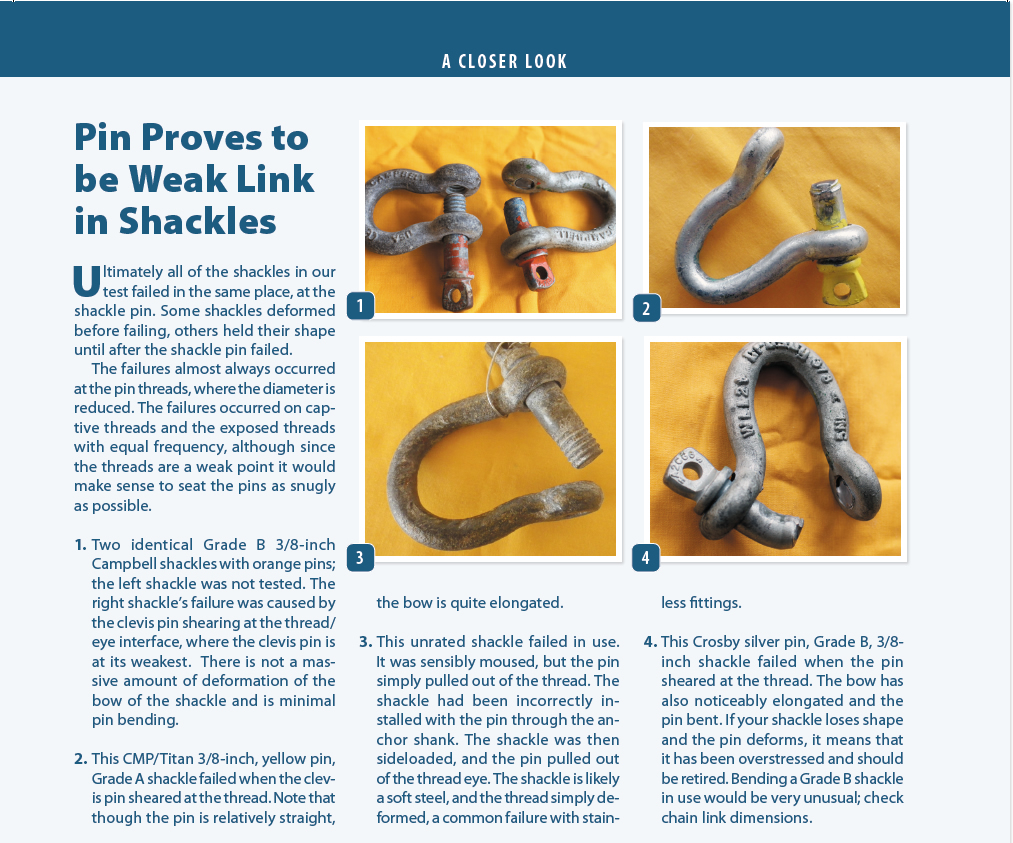

All of the shackles and the Omega link failed in the same way. The clevis pins sheared. Some shackles deformed, but it was always the pin that failed in our tests. Most of the shackle pins sheared at the threads.

It is important to note that we tested the shackles while they were perfectly aligned with the load; and the point of contact with the shackle was a rounded section. In the real world, a shackle might be side-loaded, and the slot in an anchor shank might impart a much higher point-load on the shackle. In short, the failure loads that we recorded were best-case scenarios.

Sizing and Compatibility Issues

All of the galvanized shackles we tested were effectively the same size (except the quarter-inch Peer-Lift); all were classed as 3/8-in. or 10-mm shackles (size is dictated by the nominal diameter of the bow). This means that all had 7/16-in., 11-mm pins-still small enough to fit into a 5/16-in. short-link chain. Some of the pins did not fit an 8-mm short link metric chain (which would have a 10 mm hole in the link).

The bottom line? Check fit before you buy. The dimensions of chains with the same nominal size can vary, so you may have to cut a link off and try it with your anchor to find the right match.

The 3/8-in. shackles easily fit into a wide range of 35- to 45-lb. anchors that are compatible with a 5/16-in. or 8-mm chain. If you use an oversized anchor, you will often find that the shackle you need to fit that anchor will not fit the chain, in which case, you will need two shackles, a large one for the anchor and a smaller one for the chain. In such instances, you might also find that the larger shackle does not fit the bow roller, especially on modern sailboats, which seem to be fitted with smaller and more narrow bow rollers these days.

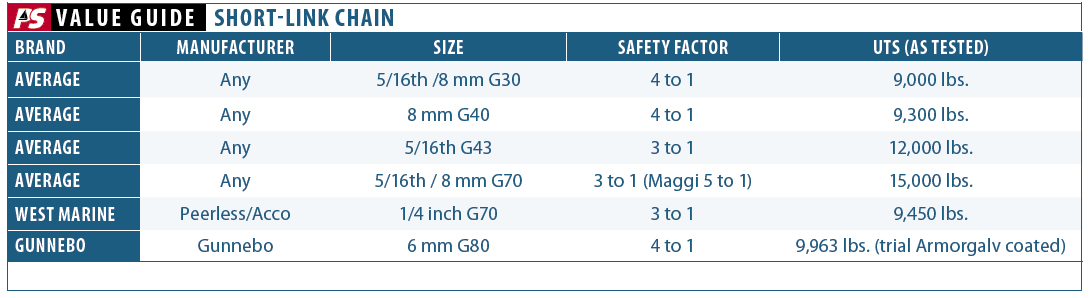

Chain Strength Benchmarks

The accompanying table gives the average results in our testing of 5/16-in. or 8-mm short-link chain. (See PS January 2015 online.) Broadly speaking, we found the following ultimate tensile stress failures (actual breaking strength) for chain, by grade: G30, 9,000 lb.; G40, 9,300 lb.; G43, 12,000 lb.; and G70, about 15,000 lb.

Campbell

Campbell has an extensive range of drop-forged, carbon steel, Grade A shackles, and a very limited range of galvanized, alloy steel, Grade B shackles. The stronger, Grade B shackles are available only in sizes starting at 3/8-in., increasing to half-inch, and then increasing in quarter-inch increments. The Grade B shackles have an orange pin.

Campbell’s 3/8-in. shackle has a rated working load of 4,400 lb. The makers specify a 5:1 safety factor; this would give it a minimum break load of 22,000 lb. In our testing, we found the ultimate tensile stress to be slightly less than the rating. The pin sheared at the thread at 21,016 lb. There was minimal deformation of the shackle itself.

Bottom line: Campbell’s safety factor appears to be slightly optimistic, but this was, overall, the strongest shackle in our test. It’s Recommended.

Crosby

Crosby anchor shackles are recognizable by a silver pin. The size range begins at 3/8 in., moves up to 7/16 in., and then increases in increments of 1/8 in. thereafter. Crosby’s range of shackles is big, too big to be used with quarter-inch or 6-mm chain, or anything smaller, including the 8-mm Maggi G70. Crosby shackles are rated by metric ton, with a safety factor of 4.5:1.

The 3/8-in. shackle we tested had a rated working load limit of 4,400 lb. with a 4.5:1 safety factor. This gives it a minimum break load of 19,800 lb. In our testing, the ultimate tensile stress was 19,905 lb., slightly above its rating. The failure was at the thread; the pin sheared. Testers noted some deformation in the eye of the shackle where the pin seats.

Bottom line: Crosby is a recognized leader in this field and fared well in our test. It’s Recommended.

Peerless

Peerless was acquired by Kito Corp, which subsequently merged with The Crosby Group in 2023 to form Kito Crosby. In early 2025, Columbus McKinnon announced plans to acquire Kito Crosby, further consolidating the lifting hardware industry. Peerless is the U.S.’s biggest chain manufacturer and best-known supplier of anchor chain, primarily through its Acco brand. It offers a complete cross-section of imperially sized chain, BBB, G30, G43, and G70; and it introduced metric G40 and G70.

It is also a major player in the lifting industry. Peerless makes a range of galvanized shackles for lifting, known as the Peer-Lift line, which it also designates for marine use.

The Peer-Lift products are forged alloy, galvanized, and individually proof-tested to two-times working load. The size range is extensive, from 3/16-in. to half-inch in 1/16-in. increments, and then increasing in 1/8-in. increments to sizes larger than 1 in. They have a shackle size to fit most situations. The shackles are differentiated from other suppliers by a blue pin. They are well suited as anchor shackles.

Note: Be careful not to confuse Campbell’s Grade A shackles, which use a blue pin, with their high-strength Grade B shackles (orange pin), or with Peerless Peer-Lift shackles which also use a blue pin.

The Peer-Lift quarter-inch, Grade B, shackle we tested had a rated working load limit of 1,500 lb. with a 6:1 safety factor. This gives it a minimum breaking limit of 9,000 lb. In our test, the shackle exceeded its load limit by almost 10 percent, failing at 9,800 lb. The failure was at the thread; the pin sheared.

Bottom line: Peerless, which also performed well in our chain test, exceeded all expectations in this evaluation. Recommended.

Canada Metals Pacific

CMP introduced a range of shackles with a yellow or black pin. The yellow pin shackles are Grade A, and black pin shackles are Grade B. Canada Metals Pacific rates its shackles in metric tons. The CMP/Titan yellow-pin, 3/8-in. shackle we tested had a rated working load limit of 2,200 lb. with a 6:1 safety factor. This gave it a minimum breaking load of 13,200 lb. Its actual ultimate tensile stress was 18,885 lb. In our test, failure was at the thread; the pin sheared.

The Titan black pin 3/8-in. shackle we tested had a working load limit of 4,400 lb. with a 5:1 safety factor. This gave it a minimum breaking load of 22,000 lb. Its actual ultimate tensile stress was 19,036 lb. Informed of this result, CMP said that although it always carries out internal shackle testing, it plans to have independent tests of its shackles carried out to ensure they meet its specifications.

Bottom line: Our Budget Buy. Stick with CMP’s yellow-pin shackles, which offer a significant margin for error; be aware that there are several other yellow-pin shackles on the market. Look for the CMP logo.

Van Beest Excel (Green Pin) Omega Link

This was a G80, 6-mm (7/32-in.) link that we had Armorgalv coated. It will fit a 6-mm, short-link chain. The working load limit is 2,450 lb., and it is made to a 4:1 safety factor, providing a minimum breaking load of 9,850 lb. Maggi provides this connector for boaters who want to downsize their chain to G70 in order to save weight, or carry a longer rode. We do not know what grade steel Maggi uses for these link connectors nor does it carry a certified load rating.

The actual ultimate tensile stress of the Van Beest Omega unit was 9,397 lb. This is below the specified minimal testing strength (untreated), but this was expected, since the Armorgalv coating process degrades strength. The clevis pin failed; however, it is worth noting that we did not secure the clevis pin with the high-tensile locking pins that Van Beest supplies for this purpose.

Bottom line: A galvanized Omega shackle is hard to find in the U.S. If you are interested in pursuing this option, contact Spencer Industries, which licenses the Armorgalv process in the U.S. This approach seems like a possible solution for boaters who want to switch to G70 chain.

Conclusion

The Peerless and Crosby shackles all met or exceeded minimum specifications, and the Campbell shackle fell short by only a whisker. U.S.-made shackles appear reliable. Note: While the brands Crosby, Peerless and Campbell are U.S.-based, ownership has globalized—Kito Crosby is a global entity, and Columbus McKinnon is a U.S. multinational.

Visually, we could not differentiate between the two grades of CMP shackles, except for the color of the pin, the embossed rating on the bow, and the price. The yellow pin model was quite impressive; the black pin variety fell short and CMP is looking into this.

Strength Comparisons

High-tensile, or Grade B, shackles when correctly sized are much stronger than the chain they match. They are two times stronger than the appropriate size G30 or G40 chain, and almost two times the strength, based on our tests, of G43. Even when you move up into high-tensile G70 chain, the Grade B shackles are still 25 percent stronger, if loaded in a straight line.

If you opt for G70 chain, you can still use any of the top-rated U.S. shackles we tested with some confidence. The CMP yellow-pin Grade A shackle we tested could comfortably be used with G30, G40, and G43 chain and would still exceed G70 strength by 15 percent.

We have not changed our views on shackle lifespan since 1998. Shackles should be considered a consumable product and should be regularly examined for corrosion at the pin or any deformation. Owners should carry spare anchor shackles and be prepared to change them regularly. They are not expensive, but they are essential items.

Buying Recommendations

It makes no sense saving a few dollars by buying an unbranded or unrated shackle. Likewise, we wouldn’t buy a Grade A shackle when a stronger, Grade B shackle is available for a few dollars more. (Be aware that these higher Grade B working load limits are often achieved by simply reducing the safety factors, so seek out the published safety factor, or UTS.) Any Grade B shackle of the maximum size to fit both chain and anchor would be more than adequate for an imperial G30 or G43 chain. Be sure to buy the maximum size possible, even if the shackle needs a bit of help to fit the anchor shank.

Metric poses a problem. To fit an 8-mm metric G30 or G40 chain, it is likely that a 5/16-in. shackle (with a pin size of 3/8-in., or 10 mm) would be required, but this shackle (working load limit of 1.25 tons) might not fit a 45-lb. anchor, which would require using two shackles. Peerless has the widest range of shackle sizes, so we would lean toward its supply in favor of Crosby. Note: Now that they are the same company, supply chains may have integrated.

Campbell also has a more limited size range. Neither Crosby nor Campbell offer shackles for the chain and anchor sizes found on smaller boats.

Imperial G70 Chain Options

If you are opting for G70 in an imperial size (using 5/16-in. chain as the example), a 3/8-in. shackle (7/16-in. pin) with a working load limit of 2 tons (12-ton minimum breaking strength) will fit the chain link. The shackle will be stronger than the chain, and would normally fit a compatibly sized anchor. Any imperial-sized galvanized Acco G70 chain will have a Peer-Lift shackle to match it.

Metric G70 Chain Challenges

Finding a mate for metric G70 is harder. A G70 8-mm chain, with its 10-mm link aperture (as measured in samples from Peerless or Maggi), should accept a 5/16-in. shackle with its 3/8-in. (10-mm pin). Try it first. One problem with G70 is that the chain’s actual break strength and the shackle’s minimum breaking strength are almost identical, thus erasing the margin of safety that shackles offer in the other combination.

A worse alternative is to use a G80, 8-mm Omega link, which in a galvanized form will have a breaking strength of 14,000 lb. (allowing for a 20-percent degradation in strength caused by the galvanizing process). It might be possible to use an Armorgalv-coated link; the Armorgalv process is not as harmful as hot-dip galvanizing. In this case, the breaking strength would be 15,750 lb. (allowing for a conservative 10 percent degradation). This puts a shackle at nearly equal strength to the chain. A final option, which we have not tried, is to use a G100 Omega link treated with Armorgalv. Even when you account for loss of strength caused by the Armorgalv process, it would still have a 20,000-lb. breaking strength.

Given that downsizing is the aim of choosing a G70 chain, the best option would be to look for imperial-sized links, as this allows more option in terms of anchor shackles.

Alternative Solutions

One final alternative, is to have larger links welded to the chain at the anchor end (or both, so the rode can be reversed). Some chain companies will do this for you when you order a large quantity of chain. The trouble here is that inevitably, the chain will corrode in certain areas (usually near the ends) and, if you decide to cut away that corroded portion, you’ll lose your big end link. (Having a local welder re-attach the bigger link means it will not be galvanized and you would need to have supreme confidence in the welder.)

Until some sensible and easy means is developed to allow an anchor to be attached to a G70 metric chain, it likely will remain only peripheral equipment.

Update: Peerless shackles, under the Peer-Lift brand, are now made in China.

This article was published on 17 July 2015 and has been updated.

I’m really glad you did this test!

But just one shackle per model? So what is the 95% confidence interval for your measurement?

In other words, how confident are you that every (for example) CMP yellow-pin shackle is identical? It would be much more informative to perform the test on some number of “identical” shackles and show error bars. As is, it’s hard to tell whether your results indicate anything.

is the first image (anchor with yellow-pin shackle) installed correctly? Looks like the pin is in the anchor, which later text says is not the right method.

I have the same question. It seems that, visually, the pin through the anchor shank and bow through the chain would be the proper fit.

Are SS shackles not advised? My understanding is that SS anchor chain is discouraged due to failure coming on suddenly, whereas carbon steel will show degradation well before failure. Same for shackles?