As sailors, once we’ve cleared the outer markers of our club, marina or harbor, we look forward to raising our sails and we enjoy that special moment when we switch off our engine to be immersed in that oh so beautiful sound when everything becomes quiet and peaceful with only the sound of the bow slicing through the water. It’s an enchanting moment for sure. To me, this is one of the things that makes sailing so joyful. Unfortunately, before reaching that blissful moment, we have to endure the unmistakable sound of our auxiliary engine. Some are louder than others.

Regardless of the size of sailboat, if an inboard engine is involved, sound levels can not only disrupt the peacefulness we seek but can also be harmful to our hearing.

Simply going in and out of the harbor is not a big deal and does keep damaging sound levels to a minimum. Especially since, normally, most people on board are still on deck. Also, a well-maintained inboard engine can also help keep the noise level down and very tolerable.

However, during those times when you motor for many hours, the sound level can become very unpleasant. Plus, trying to have any conversation while the engine is running can be very frustrating. This is the case for my wife who wears hearing aids and must remove them when the engine is running too long.

Engine Location

Where and how the engine is installed will have an impact on sound levels, measured in decibels (dB). In my case, the engine is located under the cockpit behind the companionway stairs. Although it has removeable front and rear fiberglass covers, these are not insulated and contribute to amplifying the engine sound via vibrations.

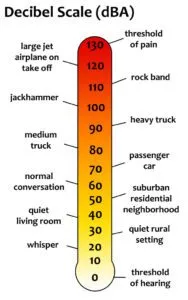

Decible Scale

According to noise level scales, anything over 90 dB starts to be harmful and anything over 70 dB for a prolonged time is mostly annoying. And of course, prolonged exposure to these levels makes the potential damage to hearing much more probable.

As an example, here are the noise level details for my engine, which is a Perkins M20, three cylinder, 18 hp diesel.

According to manuals, a Perkins M20 marine diesel engine typically operates at a noise level around 95 to 105 decibels (dB) when measured near the engine, depending on its condition and load, with the higher end representing full power operation; this falls within the standard range for small marine diesel engines.

Key points to remember:

- Noise level variation:

The actual noise level can fluctuate based on factors like engine maintenance, operating conditions and the specific boat design where it’s installed. - dB scale:

The “dB” unit indicates a weighted decibel scale that better reflects how human ears perceive sound, making it the standard measurement for noise levels.

Since, when traveling, we are often required to do so under power for long periods of time, the constant sound of engine is often a source of frustration, especially for my crew (aka, my wife) who spends lots of time in the cabin or the cockpit near the companionway.

So, I decided it was time to add soundproofing material to the engine compartment.

Measuring dB Levels

While I was confident that the addition of any quality of soundproofing material would improve the current situation, I wanted to quantify the results by measuring before and after dB levels. Although sound level meters are relatively inexpensive and available online, I opted to download a free sound meter app on my phone.

Soundproofing Material

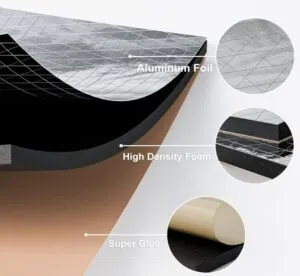

Since sound is essentially sound waves and vibrations, soundproofing material is designed to absorb vibrations. Depending on the quality, thickness and density of the absorbing material, often some sort of foam, the noise dB levels can be significantly reduced. Also, since we are dealing with the engine compartment, selecting a heat- and fire-resistant soundproofing material is essential, if not critical.

Most, sound-proofing or sound-deadening material is composed of three layers: a peel off adhesive layer, a foam sound absorbing layer and finally an outer reflective type layer for heat reflection. It can come in either rolls or various size sheets.

For my application, I selected individual panels, as they were on special and had excellent reviews. Measuring the square footage needed, I ordered the smallest pack available which was more than what I needed. The nice thing about sound proofing is the variety of dimensions and thicknesses available in both sheet format or in rolls. For those with more clearance, you can get thicker material, or like me, I added an extra layer where space allowed.

How We Tested

Before starting the application, I wanted to measure the current dB levels with the engine in idle as well as under load. I also wanted to make sure the boat was completely set-up, with her bimini, dodger, transition, etc. Since sound travels and “bounces” off various surfaces, I wanted a real-world sound measurement.

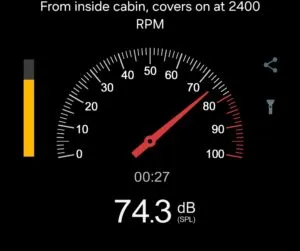

I measured the sound levels from inside the cabin as it is the where the sound is loudest, and under three conditions: at idle with engine covers off, at idle with the engine covers on and, of course, underway at 2,400 rpm—which would be the prolonged cruising speed—and once more after the soundproofing installation.

Before and After Sound Level Results

| dB levels taken from Inside cabin | Before

Covers off at idle |

Before

Covers on at Idle |

Before

at 2400 rpm |

After With sound proofing

Idle |

After With sound proofing

at 2400 rpm |

| 72.3 | 69 | 74.3 | 63.6

(- 5 dB) |

70.8

(- 3dB) |

How To Add Soundproofing Material

1. Clean Surfaces

Since the soundproofing material is stuck to surfaces, these must be as clean as possible. I cleaned them thoroughly with Dawn dishwashing soap, then I wiped the surfaces with acetone. Just before the application of the soundproofing material, I used a tack-cloth for a final removal of any dust.

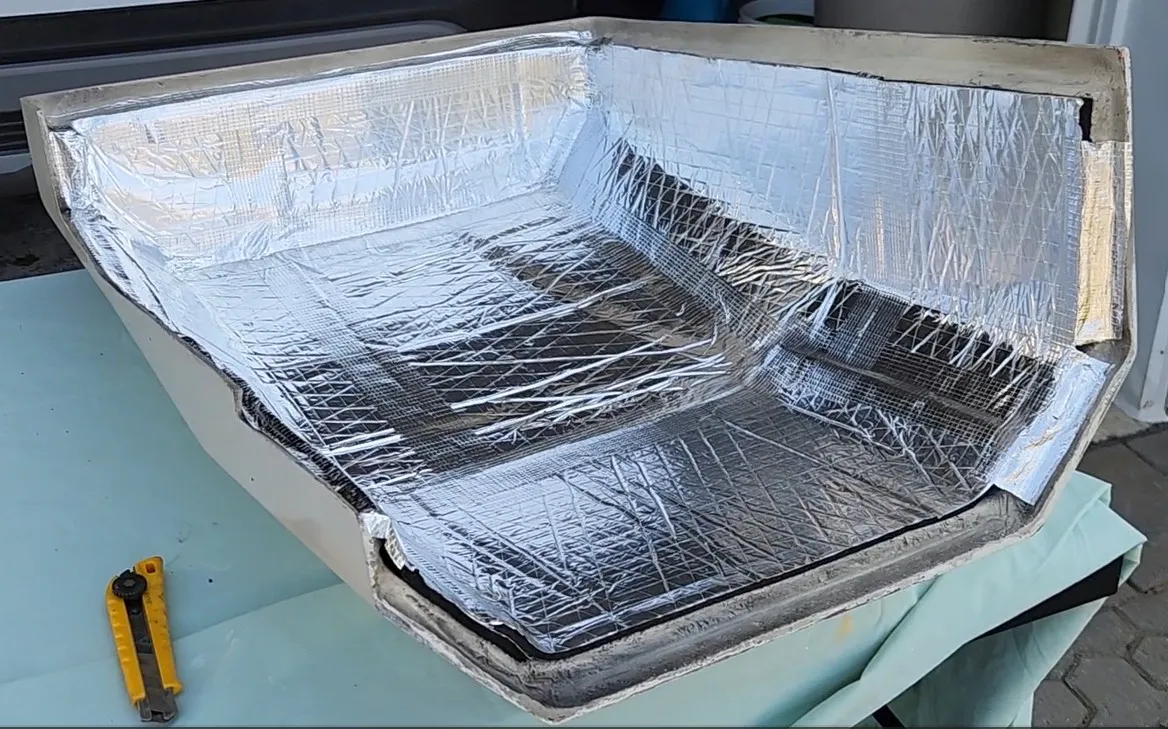

2. Make a Template and Cut Material

In my case, this project includes two removable engine compartment covers and one interior wall next to the engine. For the interior wall, I first created a cardboard template to make sure I can precut the soundproofing material ahead of the application. By laying the soundproofing material over the template I was able to cut the pieces I needed while reducing or minimizing any waste.

3. Test Fit Each Piece

Without removing the adhesive backing material, I test fitted each piece for fit and made any adjustments needed. Where pieces join together, they must butt up against each other as much as possible.

4. Stick On and Roll Flat

With the covers clean, dry and decontaminated, I peeled back each piece of soundproofing and applied them in place, one by one. After each piece, I used a wallpaper roller and a spray can to roll over the entire surface, making sure every square inch is properly stuck to the cover. On the areas where I had more clearance, I doubled up on the application of soundproofing sheet, making sure to stagger the seams.

Once all the pieces are installed, I completed the installation by applying soundproofing tape to all the joints.

Results

My two most important readings are while the engine is at cruising speed (+/- 2,000 rpm) and at idle. My particular application resulted in a 3 to 5 dB reduction in sound. This may not sound like much, but in dB readings, that does make a difference. My wife and I both noticed the sound is less sharp, more muffled and, as she said herself, is much more tolerable when we are motoring.

| dB levels taken from Inside cabin | Before

Covers off at idle |

Before

Covers on at Idle |

Before

at 2400 rpm |

After With sound proofing

Idle |

After With sound proofing

at 2400 rpm |

| 72.3 | 69 | 74.3 | 63.6

(- 5 dB) |

70.8

(- 3dB) |

All in all, for me at least, this project was inexpensive, very easy and satisfying. Plus, I got to clean the engine compartment! How often does that happen!

Product References

A couple of years ago high levels of sodium were measured in my saildrive oil. A mechanic suggested the seals were failing, or had failed. The boat is 20yrs old so I had them pull the saildrive and rebuild it. The engine had to come off the mounts to do that so I replaced the mounts at the same time. Nothing else was changed, but I noted the engine vibrated less afterwards and the sound level dropped very noticeably. It’s a small Yanmar (3YM20) so pretty quiet in any case, but crew regularly comment on how quiet it is. I think that apart from the obvious like properly securing covers and belt tension, the engine mounts (and shaft alignment if you have one) are key to how quiet the engine is.

Decibels are a logarithmic scale, so a 5 db drop really is significant.

In soundproofing my engine room, after installing sound-deadening panels, I also blocked all holes in panels and bulkheads using spray on foam insulation sealant found at any hardware store, fire-retardant orange, to fill the holes – after all hoses and wires are run. This has two benefits: It stabilizes the wires and hoses, reducing chafe, and blocks sound. It is easy to dig out when wires or hoses need to be changed, and then spray more in. I also sprayed the foam along narrow areas of wood in the engine room, say between a corner and a hatch frame where insulation was impractical. Every little bit helps.

I suggest doing a flammability test. I chose rock wool insulation because it will not burn or melt and is hydrophobic.