A New Spin on Dependable Crimps and Splices

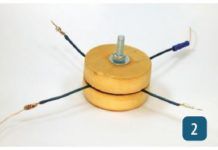

Our test focused primarily on the small-wire connections tensile strength, with and without solder, but we also looked at their durability under tough environmental conditions. We tested the pull-out strength without solder and the pull-out strength of soldered connections at 400 degrees by heating the connections in an oven to simulate overheating conditions. We tested fatigue by spinning a 6-inch length of splice wire at 650 RPM in a simple device that we called the wire-fatigue whirligig. Finally, testers soaked all samples for four months in salt water to accelerate corrosion, and then, we repeated the fatigue test.

Winter Without Worries

During my admittedly few winters above the frost belt, I have only fond memories of the last few days of the season. And Ive always admired those who didnt let the tilt of the Earth dictate the way they arranged their days.

Three Sailing Pros Speak Out

As part of our winch update and sea trial, we caucused three sailing pros and got their performance slant on what they looked for in a good winch and how they put it to use.

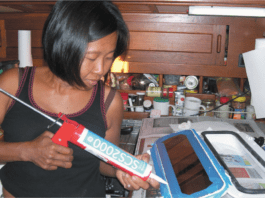

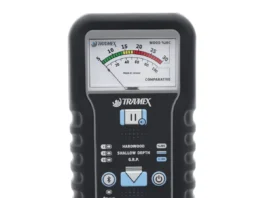

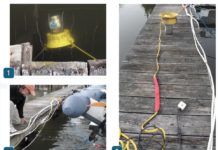

Installation Tips for Deicers

When it comes to deicers, proper installation is key. Here are some tips to ensure your setup will optimize ice removal.

Making an Anodized Mast Look Like New

Have you done any research on the best means of cleaning an aluminum mast? Im having other work done to mine and thought it would be a good time for a cleaning.

Holiday Gift Ideas for Sailors

Sailors are a practical lot. Sure, wed all enjoy a Fruit of the Month membership, but if you really want to make a sailors holiday bright, then gift them with something more useful. Weve rounded up some practical (and fun) gift ideas that any sailor would appreciate, whether theyll be decking the halls or the main saloon this season.

Testing Winches with Dale

Part 2 of our winch test this month brought back fond memories of the man who helped steer me into my position as PSs skipper, the late Dale Nouse, our former executive editor who died of cancer less than a year after I took over as editor in 2005. Dale was in charge of a winch test that year. He passed away a few months later, at the age of 82-working nearly to his last day after 13 years with Practical Sailor.

Making a Do-it-Yourself Jerry Can Drip Catcher

The previous owner of our test boat swore by using a funnel. Of course, the funnel was too small to catch nozzle leaks, reduced the flow, required holding a heavy can on a rocking deck for three minutes while the CARB can dribbled along, hoping the wind or rocking didnt move the funnel. (Sure, the flow is faster with non-CARB cans, but you had to reduce the flow for the funnel anyway.)

Floating Docks and Storm Preparation

With regard to your July 2016 article on storm preparedness and spring lines, what advice is there for storm prep for floating piers? We are in a slip with a 36-foot boat, and there is no way to cross-tie to pilings across the slip. Also, there are no cleats at the head of the slip, only on the finger pier.

Winch Grease Corrosion Tests

When it comes to most mechanical things-like wheel bearings on a car-its miles that wears em out, as my grandfather used to say. And while there are many reasons why 200,000 miles on a modern car is less remarkable than 75,000 miles was in his day, improvements in lubrication rank high on the list. Lubes of old would oxidize to sludge, stop circulating, wash out, fail to suspend dirt, and drop in pH from acid buildup-or all of these.