Sailmaker Survey Reveals Readers Favorites

Our informal online sailmaker poll generated 336 complete responses, not large enough to be statistically significant, but still useful, in our opinion. In total, readers recommended more than 100 different lofts. The responses are subjective to each respondent’s experience, making it impossible to fairly rank sailmakers based on the poll, so readers should consider this report an overview and use it accordingly in any sailmaker search. The responses can offer some insight into what can be expected of a specific sailmaker and what should be considered in the selection process.

Chandlery: August 2011

Practical Sailor Chandlery: August 2011. This month reviews a tiller, tool toter, and smart-phones.

A Peek at Inflatable-dinghy Paint Test Panels After One Year

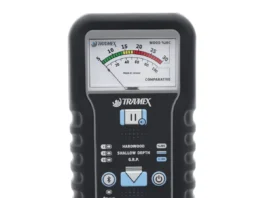

Finding a coating that sticks well to PVC or Hypalon is not easy. Because the coated surfaces are flexible, expanding, and contracting significantly as the tubes are inflated and deflated, the coating must also have some elasticity. It must also be abrasion resistant. In June 2010, Practical Sailor launched a long-term test of five paints marketed as coatings for inflatable boats. We tested products from Marine Design Research (MDR)-Amazon (Inflatable Boat Top), Flexdel (Flexabar), Tuff Coat, and Polymarine (Flexithane and Superflex). After a year of suffering the Florida sun, heat, and rain, the panels were returned to the test bench, and testers found some surprising results.

Inflatable-dinghy Paint Torture Test

Durability and elasticity are our principal comparative factors in this test, but testers also considered ease of application, coating adhesion to substrate, resistance to abrasion, and price.

What About Bottom Paint for Inflatable Boats?

If you have your heart set on applying antifouling to an inflatable (PVC or Hypalon), there are several options available. All of the so-called inflatable bottom paints are water-based, flexible coatings. Pettit Hydrocoat, Pettit Inflatable Boat Antifouling Paint, Interlux Fiberglass Bottomkote Aqua, and Sea Hawk Inflatable bottom paint (www.seahawkpaints.com) are just some of the options.

Mailport: August 2011

Letters to Practical Sailor, August 2011. This month's letters cover subjects such as: Wing Dinghy, Rope Hygiene, Multi-Pump Bilges, Water Tank Sealsnt and More!

Where Credit is Due: August 2011

Letters to Practical Sailor, August 2011. This month's letters cover subjects such as: Weems and Plath, and Moorhouse Sailmakers.

Mailport: June 2011

Letters to Practical Sailor, June 2011. This month's letters cover subjects such as: Barnacle Barrier Success, Pump Switches, Antifouling Field Report and more!

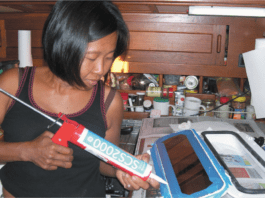

Install a Water Saver: A Galley Foot Pump

Modern boatbuilders, in their desire to make boats as appealing and comfortable as possible, have made it inherently difficult to conserve water. Plumbing fixtures work just the same as those at home. The demand pressure water pump is quick to maintain pressure and oh so quiet, almost as good as city water. Of course theres hot water aboard, even though we have to sacrifice a quart of cold down the drain before we feel the warmth. The obvious solution to better onboard water management is a manual pump, either hand or foot operated. I recognized this face a whileago, but felt that manual water pumps were for day sailors, not for bona fide cruising sailboats. Pressure water is something you graduate to after paying your dues messing with plastic water jugs and on-deck sun showers. I for one certainly didnt want to regress-even though it wouls be nice for once to have cruising agendas planned around something other than the size of the water tank.

Old Salt’s Anti-chafe Solution

Being a team of diehard do-it-yourselfers, we decided to try our own hand at devising a workable solution to defeating line chafe. After fiddling with canvas, old fire hose, and even messing around with some Kevlar, we settled on leather—an old rigger’s standby. It proved to be rugged and remained unholed after a ride on the belt sander. The fabrication process was kids craft 101, and there was something quite seafaring about the result. …