MORE 4000UV FAILURES

With regard to your recent report on the sudden failure of 3M 4000UV, I like the product for its resistance to UV (see Inside PS blog post, “PS Seeking Reports of 3M 4000UV Failure”), I have noticed that it has a very definite shelf life. I’m a former boatyard operator, and what you describe is something I’ve seen but only in the following two instances, and it seemed to happen consistently. After tracking several past projects, I concluded the failures only happened on some boats, which led me to a likely theory of:

1. The tube was frozen at some point in its life, either left in a boat or shipped during winter.

2. The tube was old, even worse if it has been opened for a while before use. I started dating tubes with a permanent marker and keeping them for no more than two weeks after opening, and the problem seemed to go away. The exception was a tube left in the yard that froze.

I have seen occasional cure issues after certain solvents were used during cleanup, the tube got too cold, the boat was too cold, the air was too dry. However, in those cases it never cured properly, and the issues were noticeable within a week. The caulk “dried” but was clearly not the same as I expected.

Boats repaired during the summer with fresh tubes of caulk did not have these problems.

I have also seen this occur more frequently with a much more expensive sealant from System Three, Silverthane SA-2100. I wanted to love it, despite being a royal pain to work with. The 2-part mixing nozzle and purported results seemed worth it. After going through two cases of product, I was stuck with months of work to re-do. I was very displeased. I actually quit buying anything from System Three as a result.

Sikaflex 291 is only okay in my experience, and I loathe the cardboard tubes. Sikaflex 295UV has worked much better, and when it’s available I use it instead of 4000UV these days. While I would be hesitant to use it below the waterline, it is more like 4000UV in the attributes I care about, not too runny, good UV resistance and long life.

Sikaflex makes another sealant that is rarely talked about among boaters, one that I have grown to love— SikaTack Drive. The product is primarily used for mounting windshields in cars.

Each tube comes with a single use primer (you squeeze the tube to break internal glass, shake, and apply with an integral bristle end). I never use it on client’s boats, because it isn’t specified for marine use. I am uncertain about it’s UV resistance, because glass typically protects it, but have had excellent results bonding mineral glass back in port lights and bedding deck hardware. However, I tool it with a 90-degree sharp edge, so there is very little exposed to UV.

It sets nice and stiff, with no sag, and you can bed things in it easily and snug up joints without too much squeeze out.

I have not tried the Loctite products you had good results with, nor have I tried the post-2018 version of 4000UV with a new formula that 3M says has fixed the issue.

Jeremy B

via PS Online

WATER FILTER

Regarding your report on water filters (see “Effective, Affordable Water Filter,” PS October 2013) I found the report very useful. It answers a lot of basic questions and helps make this concept seem feasible for my small sailboat, a 1986 J/24.

My interest in this subject is a small, but relevant element of my ongoing efforts to restore the boat, which I purchased about 18 months ago. This is a ‘project boat’ that I hope to have in the water soon, and I am looking forward to resuming sailing after a two-year hiatus owing to Covid worries, and the need to have a sailboat after selling my J/30 that I’d owned for 31 years. I needed to have something smaller, with less maintenance requirements than the J/30).

As I’m sure you will understand, I couldn’t be without a sailboat and found this refit to be well within my capabilities. However, my desire to do the job right has required more time than I had bargained for. But I have enjoyed the challenge, and I appreciate the insights that you have shared.

Bill Veno

J24

Southport, NC

If you liked that report, you should also read “Tap Water that’s Better than Bottled,” (see PS August 2015). For a comprehensive report on everything from safely catching rainwater, to choosing a watermaker, to decontaminating water tanks, check out our four-volume ebook, “Onboard Treatment, Storage.” It’s available at our online bookstore (www.practical-sailor.com/products).

STAY AWAY FROM SAND

I want to applaud your efforts at cautioning your readers of the many hazards that are present in boat yards, boats, and garages for that matter (see “Antifouling Exposure Risks,” PS May 2022). I liked your focus on simple control measures to minimize the risks. However, as a retired certified industrial hygienist I felt the need to also bring up a potential risk that your recent article seems to have minimized by the focus on the compounds present in most bottom paints. That being the risk associated with the blast media itself, specifically sand.

Many other countries prohibit the use of sand as a blasting media because of the risk presented by crystalline silica and its long history of killing and crippling workers via silicosis. Granted most of these cases are the result of larger scale blasting efforts on metal substrates in shipyards and bridges, however, even classroom art instructors have been harmed by this material, used ceramics.

As these situations have shown, even rather light handling of some of these higher concentration crystalline quartz sands can cause the material to fracture into the respirable range size. I doubt it would be different if sand is used as the blast agent to remove bottom paint on fiberglass boats. According to OSHA standards, the safe exposure limit PEL) for silica is 100 μg/m3, a number that is widely regarded as outdated and too high. The National Institute for Occupational Safety and Health’s exposure limit (REL) is 50 μg/m3. The American Conference of Governmental Industrial Hygienists’ limit (TLV) is 25 μg/m3.

In your blasting scenario, you estimate the copper levels would be in excess of 8,000 percent of the OSHA PEL, which for nuisance dust would be 10mg/m3. The estimates in a number of other industrial studies have shown that the crystalline silica concentration outside of the blast helmet would be in the range of 50 times the NIOSH REL or approximately 2,500 μg/m3.

If your math is correct, the concentration of crystalline silica would be even higher than the assigned protection factor for a supplied-air respirator. This, of course, doesn’t include the risk to helpers wearing only half-face piece respirators, if anything. Nor does it include the residue that is left on the workers clothing and the spread outside of the containment tent.

Unfortunately many families have had significant exposures when cleaning the worker’s clothes, and the common practice of spraying off with an air hose is obviously a bad way to contain potential exposures.

I bring this up simply because for whatever reason the phrase “sand-blasting” is the common jargon and unfortunately still leads folks to use sand as a blasting agent, when many other non-crystalline quartz- containing products exist that can do the job.

As your article mentions there are soda blasting agents. Blasters also use dry ice, furnace slag, walnut shells and sponge jet — essentially tiny rubber bullets. All of these do a good job of capturing all the nasty material that the blasting takes off.

Bottom line, I hope in the future that all boat owners ask contractors what they are going to use a blast agent. Or even better, refuse to use sand as a blasting agent on your boat. This will be a step in the right direction. So, if we can, let’s replace the words “sand- blasting” with simply “blasting.” Delinking the two might eventually help change the way folks think about the issue. When it comes to blasting, there are many better options than sand.

Kevin Grice

via PS Online

TOOL BAGS

Regarding your recent report on toolkits, (see “Tool Kits For Every Possible Boat Job,” PS July 2022), I can’t help but add another source for a fantastic tool organization bag. Veto Pro Pac (www.vetopropac.com) makes probably the best tool organization bags on the market. I’ve had one for over 10 years, used it in some of the most harsh environments in Africa as well as on my boat. This tool bag has not only stood the test of time, but continues to far exceed other manufacturers’ bags for durability, storage capacity, access and transportability. They are so good that I’ve purchased several of them as gifts for my sons, who are also do-it-yourself’ “experts”.

Lello Galassi

Tara, Kelly Petersen 46

Bellingham, WA

Fall is sailing season for snowbirds who migrate south to join their stored boats, and early fall can be overwhelming as you try to catch up on projects from the previous season. Whether you are itching to get moving or are happy to keep tinkering through October, the PS Online archives have got you covered.

WOOD FINISH

Modern polymers have made the job of protecting wood easier, but we’ve also found some tried and true tung oil products that do well. Search “wood finishes” with our online tool for a bucket-load of articles on products and application tips. Our most recent test report (PS August 2021), and the application and gloss report (June 2015) provide comprehensive coverage and links to previous reports.

RIG INSPECTION

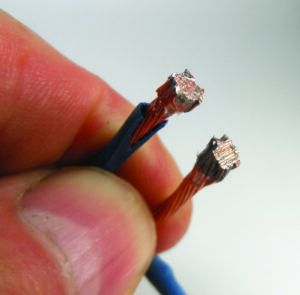

Freeze and thaw cycles can creep into rigging terminals, and hidden corrosion can leave your rig vulnerable. If you’ve not yet stepped your mast, inspection is easier. If you have stepped it, it’s time to climb. In any case, we have you covered. Search “rig inspection” at PS Online. The late Brion Toss’s “Hidden Causes of Rig Failure,” is a great start.

CLEANING

Still scrubbing? Check out our test reports on boat soaps (PS January 2013), waterline stain removers (PS April 2014 and November 2007), isinglass/clear-vinyl cleaners and protectors (PS May 2014 and March 2009), and hull waxes and polishes (Inside Practical Sailor blog and July 2014 PS issue). Our four-volume report on Marine Cleaners in the PS Online bookstore will ensure you’ve got everything you need (www.practical-sailor.com/ products).

ELECTRICAL SYSTEMS

Whether you’re embarking on a complete overhaul of your boat’s electrical system, troubleshooting annoying electrical problems, or want to ensure your batteries, conductors and connectors can withstand the rigors of an offshore voyage, our six-part ebook on electrical systems will guide you through the process. The newly updated ebook Electrical Systems – The Complete Series is available at our online bookstore (www.practical-sailor.com/products).