With all of the products out there claiming to be green or non-toxic, surely there must also be villains that are now best avoided. In just a century weve begun to make a fine mess of the world that we need to live in for the next few million years. Yet we are making progress, and finding less hazardous replacements is a part of the answer.

But as we pawed through advertising hype, reader suggestions, and product specifications, we found half truths, misleading statements, and just plain lies. We found some chemicals that are merely useless, and some that don’t work right. Even if youre not a rabid eco-warrior, regard chemicals as you would a power tool-it can also bite if you are careless. Its about tool safety.

A list of chemicals the EPA has determined to be safer choices can be found at https://www.epa.gov/saferchoice/safer-ingredients.

The Toxic Six

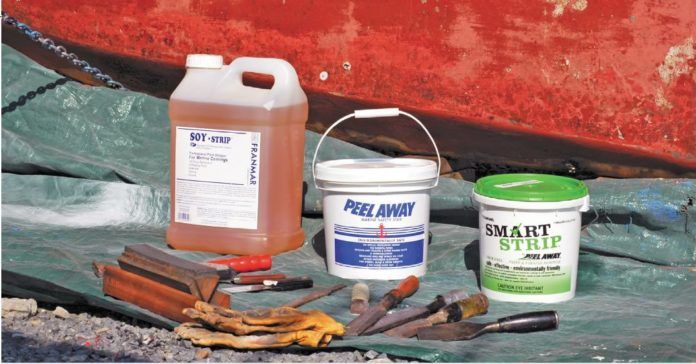

Paint strippers are among the most worrisome chemicals boaters encounter. The EPA is thinking about banning methylene chloride and NMP, and based on the risk assessment, no matter the legal outcome, we strongly recommend not using them. Dumand Smart Strip is the only NMP-free paint stripper that has tested well for Practical Sailor, but were sure others will be reformulating.

Methylene Chloride (dichloromethane)

Common in old-school paint strippers, including Kleen Strip Premium, this chemical is a listed hazardous waste (F002, the assigned hazardous waste code for this spent solvent), and all contaminated paint sludge will be hazardous waste, even after it is effectively dry. It is multi-organ toxic, very volatile (fatalities have been associated with high vapor concentrations), and bad for the environment. The EPA is currently considering a production and importation ban.

NMP (N-methylpyrrolidinone)

Known to absorb very rapidly through the skin, and recently recognized as very dangerous to women, the EPA has determined that even gloves and respirators cannot provide adequate protection for exposures to NMP over four hours and has even considered banning retail distribution as possible course of action. It is also multi-organ toxic. Ironically, many of the latest crop of green and safe strippers are based upon NMP (Sunnyside/Back-to-Nature Aqua Strip, Franmar Soystrip, West Marine Paint Stripper), changing the hazards, but not decreasing them. The EPA is currently considering a production and importation ban.

Other Options. Caustic strippers, reviled for the skin burns and eye and inhalation hazards, have largely been replaced by solvent and NMP-based strippers. At least with caustic strippers you can protect yourself from chemical burns, and heal without lasting concerns. We still like Easy OFF Oven Cleaner for small removal projects; easy to use and we have it at home. Wash skin frequently when working. Solvent strippers based on toluene, alcohol, and ketones (Interlux 299e) have flammability and inhalation risks-wear a respirator.

Replacement. Smart Strip (Dumand) uses benzyl alcohol, which is listed as generally accepted as safe in food (tiny amounts). Dibasic esters (dimethyl succinate, dimethyl glutarate and dimethyl adipate), acetone, and methanol are all acceptable ingredients.

In addition to sanding, abrasive blasting, commonly with washing soda, is becoming popular and less expensive.

Formaldehyde

Used in a old-school chemical holding tank deodorants (mostly discontinued, but we still run across old stock) this noxious chemical has been banned from holding tank deodorants in several states, banned from National Park camping sites, and has no place in any boat or RV. It is listed as a probable carcinogen. If thats it doesn’t work as well as natural approaches we have tested. Formaldehyde is also released by polyurethane expanding foams if improperly cured.

Replacement. You have many better options to choose from. Use a holding tank treatment such as Odorlos, No Flex Digestor, Forespar, Refresh, or Camco Ultra Concentrate. These are based on nitrate or enzymes and work with naturally occurring bacteria to control odor and liquefy waste. See Stopping Holding Tank Odors, Part II, Practical Sailor, December 2012.

Quaternary Amines

Used in disinfectants, algae control chemicals, and some holding tank treatments, these compounds have extreme marine toxicity, generally lethal at less than one part per million (PPM). They have no place in holding tank treatments (West Marine ExterminOdor), where they will be discharged either to the sewer or the environment in significant quantities. Key ingredients are BAC (benzylalkonium chloride), ammonium chloride, and related chemicals.

Replacement. Used as a disinfectant, products should be diluted to no more than 1 percent active ingredient concentration, and only the minimum quality should be used, preferably away from the water (these are relatively safe on land, as they degrade rapidly). Chemical holding tank deodorants should be replaced with natural alternatives.

Mercury and PCBs

An inadvertent legacy of industrial development has been contamination of our waterways, and as a result, the fish in them. Follow EPA advice, https://goo.gl/HYd3vD. If you have a bilge pump switch that uses mercury, be sure to dispose of it properly. Our last bilge pump switch test (see Bilge Binge, January 2006 Practical Sailor online) featured several non-mercury switches that proved reliable.

Replacement. While eating fresh fish is one of the great joys of sailing, you need to monitor consumption in some areas. Large fish accumulate higher levels, so catch smaller fish.

Perchlorate

A common oxidizing agent in signal flares, there is little potential for exposure, since most of us will never use a flare. Unfortunately, the most common (and wrong-headed) flare disposal method is to dump them off the back of the boat. Perchlorate is a potent thyroid toxin and likely human carcinogen, is extremely durable in the environment, and is known to accumulate in the food chain.

Replacement. Get an electronic flare or dispose of flares properly.

The Not So Dirty Three

Some folks see these are bad actors, but perhaps they just require common sense and safe work practices.

Acetone

Extremely flammable and quick evaporating, this solvent must be used with considerable care to avoid creating a flammable atmosphere in a confined space. It can make you dizzy, leading to falls and other accidents. On the plus side, it is also low in toxicity, degrades very rapidly in the environment.

Safe Practices. These include working where there is good ventilation, and using an organic vapor respirator as required. Limit the amount used, remove soaked rags and materials from the work area as soon as possible, and do not leave containers open. Avoid open flames and do not use spark-producing tools, including power tools.

Hydrochloric acid (muriatic acid)

The worker hazard is that of chemical burns and fume exposure. These are easily managed through same handling practices. Once neutralized it becomes salt water, and assuming you use only as much as needed, the acid released into the environment is like naturally occurring acid.

Interestingly, most of the hardware stores that previously carried 30 percent hydrochloric acid have switched to green hydrochloric acid. First, the green statements is without basis, since it is exactly the same chemical. Second, the claim that it reduces fumes by 90 percent is true, but only because they concentration is reduced from 31.5 percent to 20 percent. So technically, it is a little safer to handle, more expensive (you need more), and by no means is it more green.

Safe Practices. Dilute the acid in the open air, not below decks. To reduce spattering and heat, pour acid into water, not water into acid. Wear appropriate protection (gloves, goggles, waterproof suit, respirator) as needed, and have flowing water available for rinsing.

Bleach

There is a concern that bleach can damage finishes, fabrics, and ropes. First, most exterior materials are extremely bleach-resistant by design; if they were vulnerable to bleach, they would be destroyed by the sun. It is a matter of controlling concentration and exposure time. Bleach can be very caustic if allowed to dry; make certain the work remains wet at all times. Bleach can create hazardous chemicals as by-products. Always clean first with soap before using.

Safe Practices. Sodium percarbonate (the active ingredient in Oxyclean) is a safer alternative. Its on the EPA safe list. This does NOT replace bleach for water purification, where chlorine and bleach remain the EPAs favorites.

The Annoying Three

These require caution, not so much because of health hazards, but because they cause practical problems.

DEET

Although proven as the most effective mosquito repellent, there are questions regarding health if over-used. A clearer impact, however, is that DEET can ruin many plastics on contact.

Solution. Ban aerosols containing DEET from the boat. Avoid sunscreen/DEET blends. Keep a washcloth handy for cleaning your palms after applying DEET. Finally, if the real problems is flies, switch to catnip oil-it is more effective, less messy, and safer for your health and the boat.

Silicone Sealants

Silicone has superior chemical resistance (gasoline, fuel, and oil) and specific grades are excellent for bonding polycarbonate and acrylic glazing (polyurethanes and polyethers cause crazing), but if you use it for bedding or general sealing, you will find that nothing sticks to silicone contaminated surfaces, not even new silicone.

Solution. Re-Mov does a good job of removing silicon and silicone residue from most surfaces. (Practical Sailor Tests Adhesive Removers, Practical Sailor, January 2017.) Switch to polyurethane caulk when you need bonding, and butyl caulk for easy removal.

Propylene Glycol

We need a non-toxic winterizing agent, and ethanol falls short-it is too prone to fermentation, corrosive to metals, and damaging to hoses and other elastomers. Ethylene glycol (EG) is dangerous around potable water systems. However, propylene glycol (PG) is very hard on clear plastic strainers (crazing) and neoprene impellers (stiffening and cracking), and can ruin these parts in just a season or two.

Solution. Use ethylene glycol for all non-potable water winterizing needs-there is no difference between EG and PG in marine toxicity or biodegradability. They only differ in their toxicity to mammals, and unless you plan to sip from your holding tank, the risk is nil. Where Propylene glycol must be used, be sure to remove all clear strainers and impellers to the extent practical, blow out with air, and winterize for the minimum practical period of time.

Conclusion

The best solution is to minimize the use of chemicals. Remove paint mechanically, or use ablative paint and avoid the problem entirely. Clean the boat with plain water, spot cleaning stains. Winterize by blowing out lines and draining. Less is more.

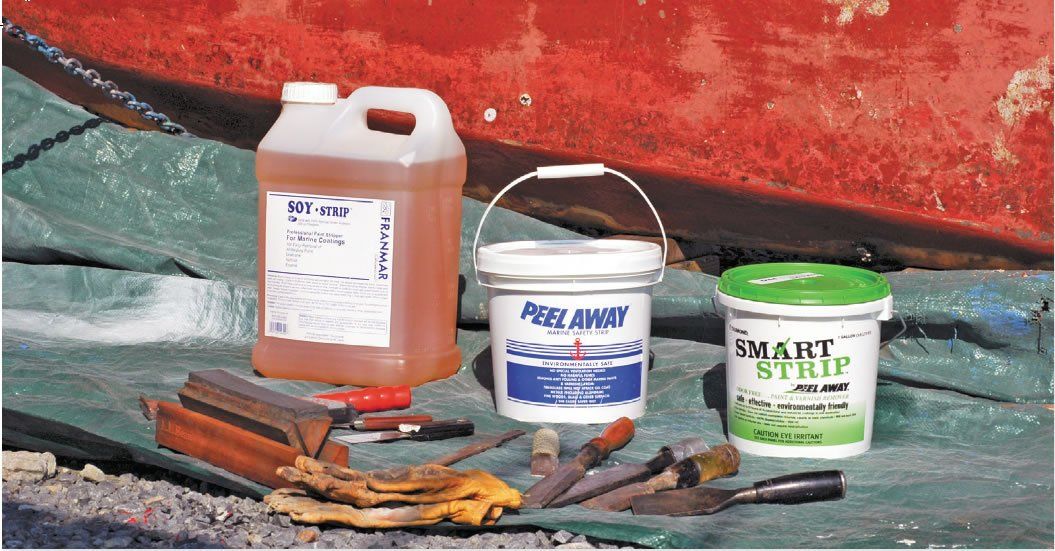

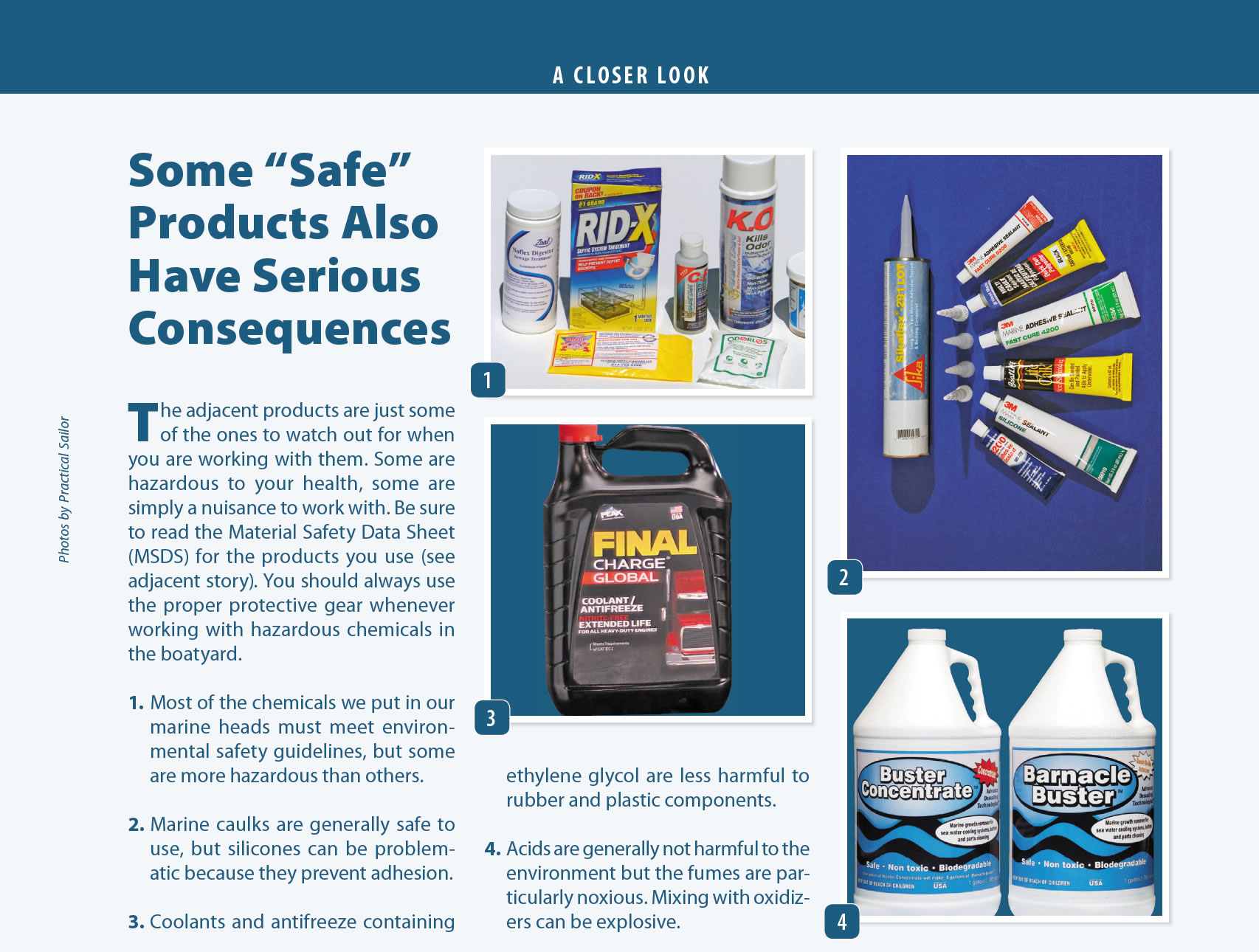

The adjacent products are just some of the ones to watch out for when you are working with them. Some are hazardous to your health, some are simply a nuisance to work with. Be sure to read the Material Safety Data Sheet (MSDS) for the products you use (see adjacent story). You should always use the proper protective gear whenever working with hazardous chemicals in the boatyard.

1. Most of the chemicals we put in our marine heads must meet environmental safety guidelines, but some are more hazardous than others.

2. Marine caulks are generally safe to use, but silicones can be problematic because they prevent adhesion.

3. Coolants and antifreeze containing ethylene glycol are less harmful to rubber and plastic components.

4. Acids are generally not harmful to the environment but the fumes are particularly noxious. Mixing with oxidizers can be explosive.

Continue the theme please. A similar summary of healthy work practices in the boat yard, dust control techniques, respirators tips, etc should be beneficial as well.

Unfortunately I know of a fatality of a boat yard guy doing solvent and painting work within the recesses of a sailboat, confined space situation.