The loads of a flying jibe in late summer squall are enough to shred sails, rip out deck or boom fittings, bend or break the boom gooseneck, or even bend the boom itself. The novice sailor learns very quickly to be wary of an unintentional jibe.

There are three approaches to minimizing the carnage of an unintentional jibe. The first method is to use a preventer. The second method is to slow the boom by using a braking device. Common braking devices use a control rope and a friction-device to provide adjustable restraining force. Finally, you can use more elastic lines in your running rigging (mainsheet and/or traveler) or add short nylon snubbers in your existing running rigging to absorb some of the shock.

What We Tested

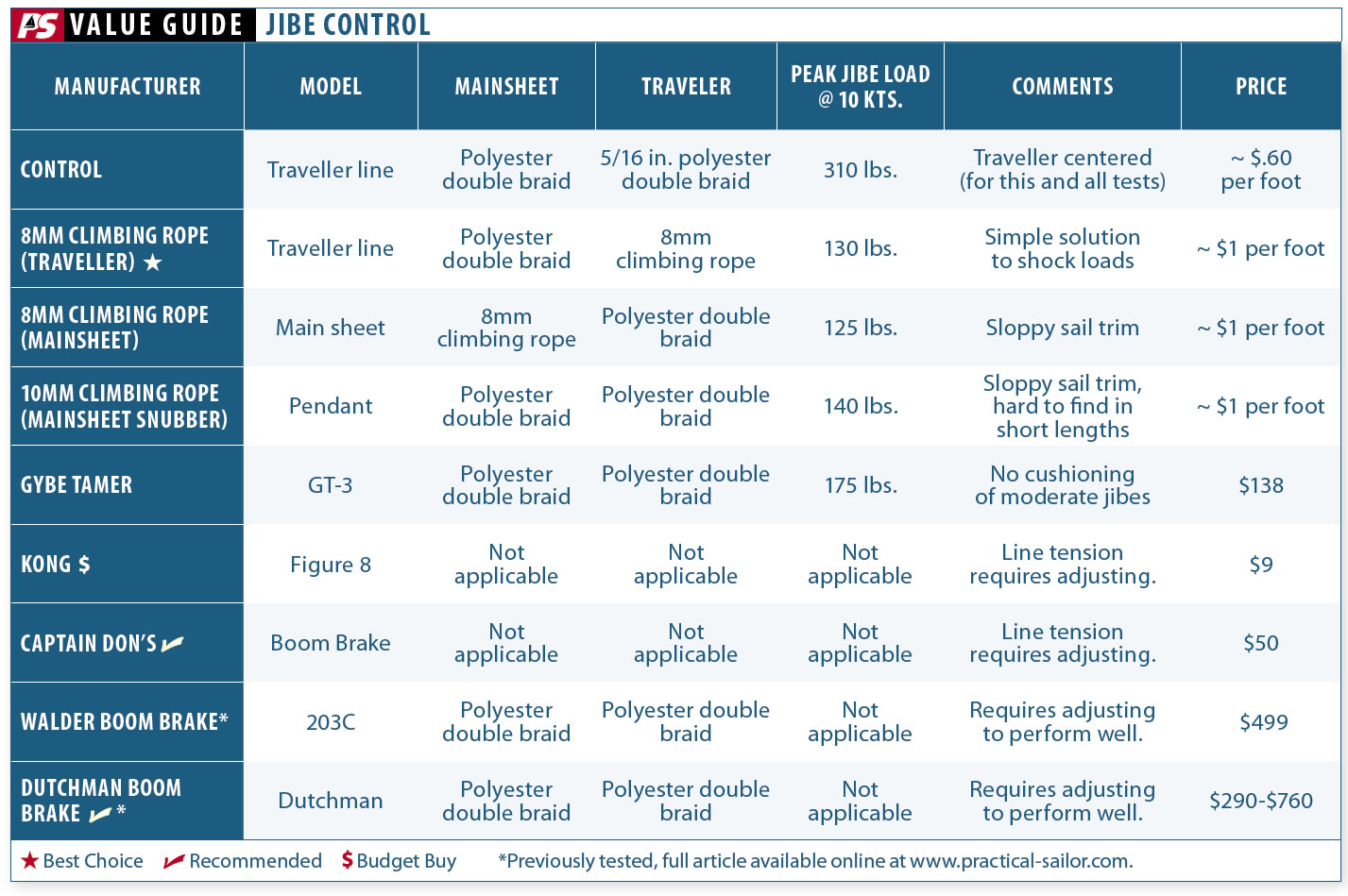

We tested two types of load-reducing devices: shock absorbers that reduce the peak loads on the mainsheet and associated hardware; and friction devices (brakes) that rein in the boom as it crosses the deck. Weve looked at both types of devices before. In Testing a Dynamic Traveler (Practical Sailor, January 2016), we evaluated the effect of using a moderately elastic climbing rope for the traveler line. In What Can a Boom Brake Do For You? (Practical Sailor, January 1994), we looked at the Walder Boom Brake and the Dutchman Boom Brake introduced by Martin Van Breems, developer of the Dutchman sail-flaking system (see “Taming the Main,” PS February 2008).

Among the shock-absorber approaches, we tried climbing rope in three configurations: in the traveler, as a snubber between the mainsheet fiddle block and boom bail, and finally, as a replacement for the mainsheet itself. We also tested the Gybe Tamer GT-3, a pneumatic tension device.

In the friction device category, we looked at a climbers figure-8 device and Captain Dons Boom Brake, which is a marine version of the climbers figure-8. (The French company Wichard makes a similar, the Gyb’Easy, that we plan to test in the future.) The results of our tests are shown in the adjacent Value Guide (Right) Jibe Taming Devices, which also includes data on the products in the first test.

How We Tested

We attached a load cell between the boom and mainsheet to gather baseline load data. The traveler was centered, and the mainsheet was slack, allowing the boom to set just aft of the shrouds when the boat was sailing downwind. We recorded peak loads when jibing and while sailing to windward. We then tested each shock-absorbing device in sequence. Concerned about possible equipment damage, we did not try to record loads in winds greater than 12 knots.

After the initial light-wind testing, we compared the climbers figure-8 and Captain Dons Boom Brake in winds up to 20 knots true wind. We tried each device attached at two locations: toward the forward end of the boom (where a boomvang might attach) and at the boom end.

Shock Absorbers

Because our load cell had a 1/2-second sampling rate, we could not be certain to capture the brief peak force when the traveler car smashes into the end of the track. For this reason, and to avoid the risk of any damage to the traveler car, we kept the traveler centered.

Dynamic Traveler Line

(8 mm climbing rope)

This rope was featured in the previous Practical Sailor report (Testing a Dynamic Traveler, January 2016), and has now been in regular use for five years. Ours came from Mammut, but other brands are available through rock-climbing equipment suppliers. After several tests and load calculations for higher winds, it appears quite difficult to reach peak loads that might harm any gear when this traveler line is in place. At maximum load, it simply stretched a few inches to leeward.

Bottom line: In field-testing, dynamic line wears slightly faster than polyester double-braid, depending on the traveler design, but it is still worth the extra expense in our view. See the Testing a Dynamic Traveler for more details. This is our Best Choice for cruisers and racers alike.

Nylon Pendant

(8 mm climbing rope)

A pendant for the mainsheet is standard equipment on some boats; it reduces weight and removes some mass from the boom end. We werent impressed with the way it worked on the test boat, because it allowed the mainsheet to twist too much, and shock absorption was no better than a nylon traveler line.

Bottom line: This might work well with for smaller boats with smaller power ratios on the mainsheet.

Gybe tamer GT-3

Made in Great Britain, the Gybe Tamer looks like a heavy-duty door spring and operates the same way. It extends as wind pressure increases, but during a rapid jibe it retracts, pulling a few inches of slack as the boom crosses the boats centerline. When the mainsheet loads up again at the end of a jibe, the Gybe Tamer extends again to absorb the shock.

The Gybe tamer comes in three different sizes to match mainsail area: GT-1, up to 162 square feet; GT-2, 162-353 square feet, GT-3, 352-485 square feet, and custom larger sizes. To function properly, the sizing needs to be correct, because there is no way to adjust the tension. All the Gybe Tamers are the same length compressed (8 inches, pin to pin) and extended (12 inches, pin to pin). Cruising catamarans don’t heel to absorb energy and spill wind, so they will likely require a device that is one-size larger than the recommended size.

We used a GT-3 on a 32-foot, 9,000-pound catamaran with a 350 square-foot mainsail. With the mainsheet trimmed and the boat sailing upwind, it began to extend when the wind reached 12 knots. A drawback is that the device can only absorb 80 foot-pounds of energy. By comparison, the setups incorporating climbing rope continued to stretch and absorb energy as loads increased well beyond 80 foot-pounds. Interestingly, the Gybe Tamer would not extend when we tried it in conjunction with the nylon dynamic traveler line. The rope apparently absorbed all load during the jibe.

The makers suggest installing the device either at the traveler or on the boom. The boom is preferable; if it is mounted on the lower mainsheet block it can flop around on the deck in light winds, potentially scratching the gel coat.

Bottom Line: Inserting this device into the mainsheet tackle adds several unnecessary complications. If the Gybe Tamer offered clear benefits over some of the other methods we tried, we might recommend it-but it doesn’t.

Boom Brakes

A boom brake requires careful attention to rigging details. It must be attached to the boom far enough aft to apply leverage. Generally, the recommended attachment point is located about 1/3 of the length of the boom aft of the mast. If installed too far forward, the braking force is inadequate or inconsistent. It is also critical that the anchor points on the deck and boom are situated so that the control line can maintain tension throughout the jibe.

Don’t use high-modulus (low-stretch) line. Tension on the control line varies as the boom crosses the deck, and a moderate amount of stretch helps control friction. Excessive stretch, however, can cause inconsistent braking. We liked a very limp 3/8-inch polyester double braid like Samson LS when the brake was positioned at the boom end, and 1/2-inch Samson LS when the brake was positioned forward. We found that stiff line would often jam up partway through the jibe in lighter winds even if we released tension completely. In these cases, we would have to go forward to free the boom-something we like to avoid. Most sailors lead the control line to a winch to adjust tension, others use block-and-tackle to add tension, but this adds clutter to the side deck.

A boom brake can also serve as a preventer if you intentionally over-tension the control line, a tactic used by some singlehanders. The arrangement allows them to lock the boom with a single line and quickly release the boom after a jibe/knock down, all from the relative safety of the cockpit. A boom brake is not as effective as a true preventer (see illustration), though. In our on-the-water tests, the brakes allowed enough boom movement for the sail to fully back, when a conventional preventer would have only allowed a flutter.

Another downside to a boom brake is that the control lines exert a downward force that affects sail shape. If the control line is eased enough to allow proper mainsail twist, as soon as the mainsail begins to back, the boom drops, the control line goes slack, and the boom can whip across.

The problem with these devices is that ensuring a controlled jibes requires finding the right line tension and wraps as wind speed changes. Part of the reason for this is that a jibe starts with a light nudge, as the wind first gets behind the sail, then reaches a peak as the boom crosses the centerline, and finally requires massive braking force as it approaches the spreaders.

Kong Figure 8

Figure 8s are commonly used in climbing to control descent on a single line. Several virtually identical figure 8s are available from climbing gear companies. They are rated to 7,850 pounds and will slide at less than 2,000 pounds. We can’t imagine a scenario in which the figure 8 itself would fail, as some proponents of marine boom brakes suggest. Although a climbers figure 8 lacks the extra hook that boat-specific brakes add to make it easier to adjust friction, you can make two wraps to increase friction in higher winds. Made of anodized aluminum, corrosion should not be a problem.

Bottom Line: Because of the relatively low price, climbing figure-8s are recommended for anyone looking for an inexpensive way to experiment with a boom brake.

Captain Dons Boom Brake

Made from 316 stainless steel, Captain Dons Boom Brake is a maritime evolution of the figure-8, offering greater range of friction adjustment, which can be easily tweaked by looping the control line over a small hook in the top circle (see photos). Although looping the control line over this hook resulted in a jerky release during our testing in higher winds, the smoother stainless-steel finish resulted in a more predictable motion in the low-wind settings compared to a climbers figure 8.

Bottom Line: Captain Dons Boom Brake and similar marinized figure-8s are a good solution for boats 25-40 feet who have a little extra money to spend on deck gear and prefer stainless steel over anodized aluminum.

The Walder and the Dutchman were not retested, since they are unchanged since our last test. In that report, testers reported similar problems to those we found in this test. In order for these devices to work properly, the sailor needs to make frequent adjustments to the control line to ensure the correct amount of friction. The full report on these devices will be linked to in the online version of this report.

Conclusion

A traveler control line that uses dynamic climbing rope offers a simple way to greatly reduce the risk of damage during an unintentional jibe, but it will not slow down the booms potentially dangerous traverse. For this reason, some boaters may be more satisfied with one of the devices we tested. A stretchy nylon pendant, because it is so short, doesn’t offer adequate shock absorption on bigger boats, but it might make sense on smaller boats, if it fits.

As for the boom brakes: in lighter winds, testers found that adjusting friction was a nuisance, and once we added a shock-absorbing traveler line, the braking device was superfluous. In moderate wind, getting the right adjustment required some practice-too much friction and it would not jibe, too little and it jibed hard. Moreover, the lines were always in the way and required adjustment with every significant change wind speed. Neither of these problems will bother the sailor embarking on a long tradewind passage, but coastal cruisers in variable wind regions might find a boom brake to be more trouble than it is worth.

At the end of testing, we removed the boom brakes and returned to using fixed preventers to prevent unintentional jibes. To help absorb shock loads during a jibe, we used a traveler line made of climbing rope. Finally, we perfected our jibing routine, carefully handling the mainsheet to minimize shock loads. Weve met a sailors who sing the praises of their boom brake, and single-handed racers use them as well. However, for most sailors, simply changing to a moderately elastic line in the traveler and using a preventer when needed will offer adequate protection against gear damage-but you will still have to keep your head down.

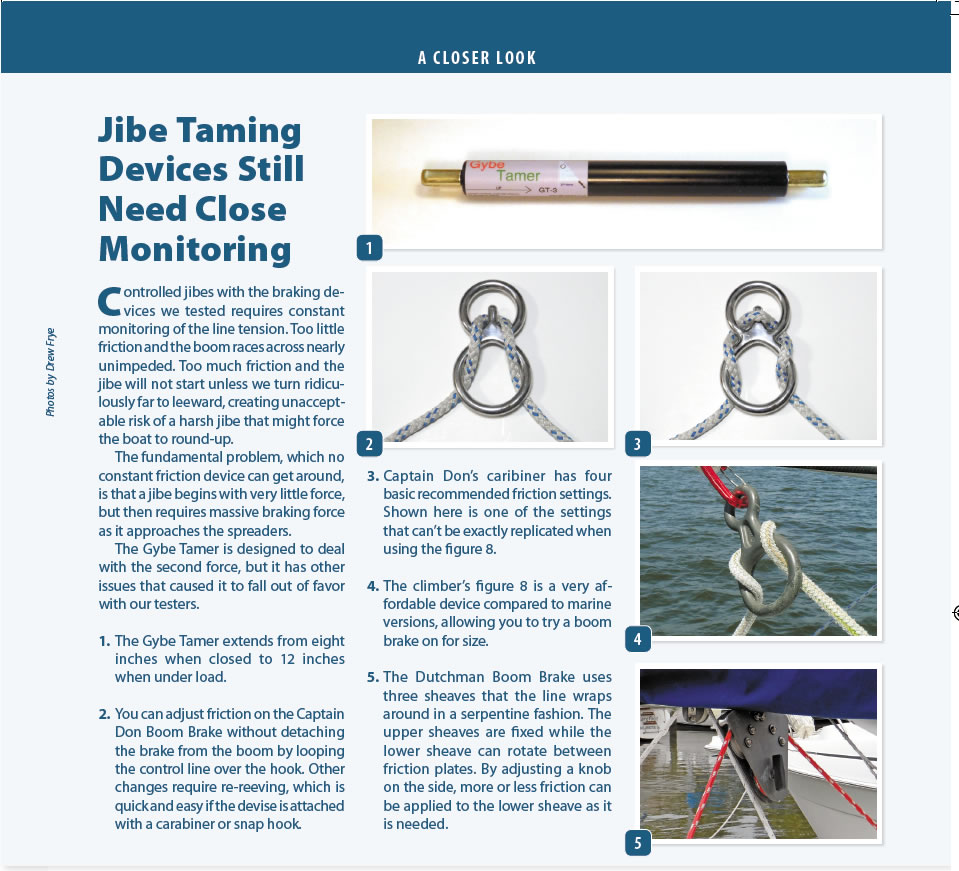

Controlled jibes with the braking devices we tested requires constant monitoring of the line tension. Too little friction and the boom races across nearly unimpeded. Too much friction and the jibe will not start unless we turn ridiculously far to leeward, creating unacceptable risk of a harsh jibe that might force the boat to round-up.

The fundamental problem, which no constant friction device can get around, is that a jibe begins with very little force, but then requires massive braking force as it approaches the spreaders.

The Gybe Tamer is designed to deal with the second force, but it has other issues that caused it to fall out of favor with our testers.

- The Gybe Tamer extends from eight inches when closed to 12 inches when under load.

- You can adjust friction on the Captain Don Boom Brake without detaching the brake from the boom by looping the control line over the hook. Other changes require re-reeving, which is quick and easy if the devise is attached with a carabiner or snap hook.

- Captain Don’s caribiner has four basic recommended friction settings. Shown here is one of the settings that can’t be exactly replicated when using the figure 8.

- The climber’s figure 8 is a very affordable device compared to marine versions, allowing you to try a boom brake on for size.

- The Dutchman Boom Brake uses three sheaves that the line wraps around in a serpentine fashion. The upper sheaves are fixed while the lower sheave can rotate between friction plates. By adjusting a knob on the side, more or less friction can be applied to the lower sheave as it is needed.