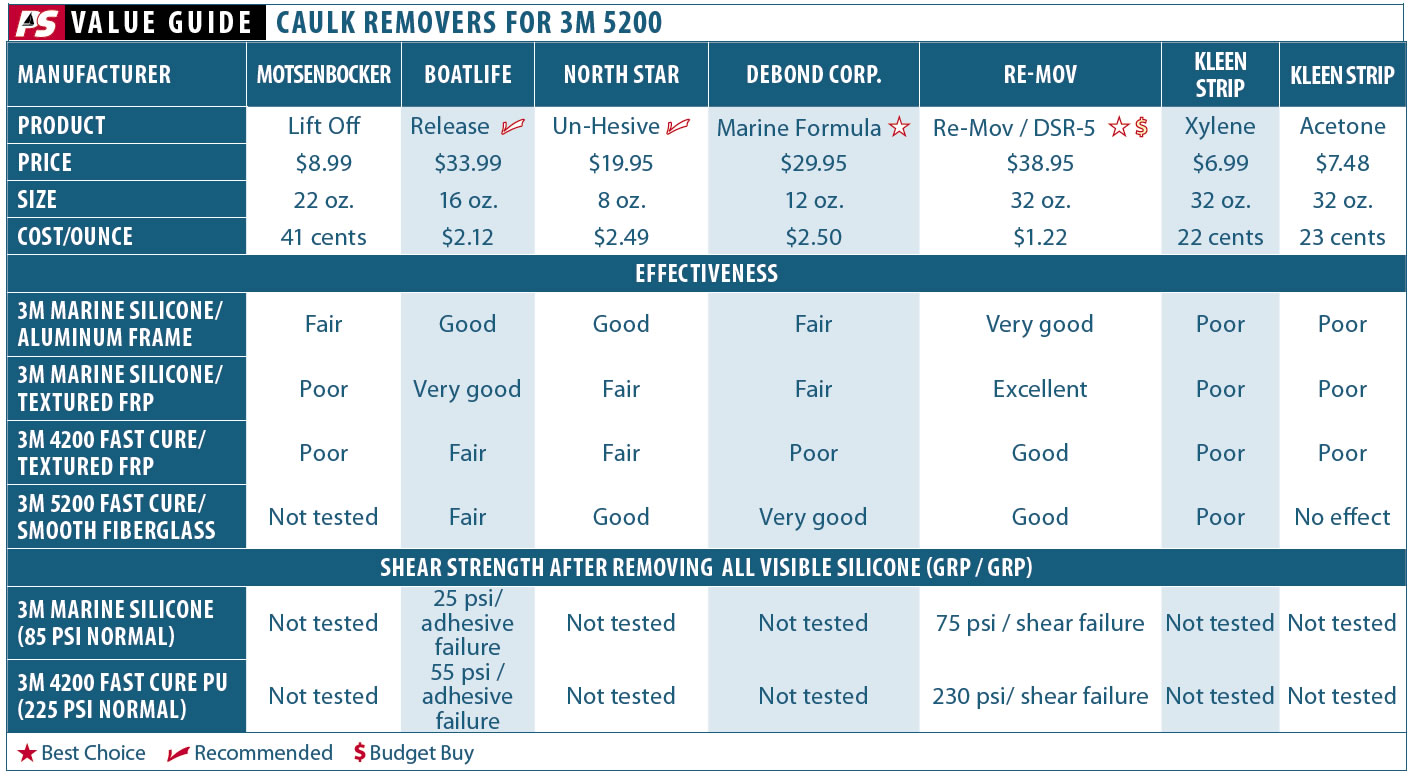

Our recent test of caulk removers, (PS Tests Caulk Removers, Practical Sailor, January 2017), focused primarily on silicone caulk remover because these caulks can leave a residue that makes it impossible for anything to bond. After that test, we got a call from reps at Debond who explained that their product, although effective with silicone, is formulated to break the bond between to break the bond between 3M 5200 and a smooth gel coat surface. This is a common challenge for sailors who must disassemble through-hulls, remove chainplates, or repair structural components. So we went back to the lab to find the best antidote to 5200, and we present the results of our tests here.

Photos by Ed Sherman

What We Tested

We tested DeBond Marine Formula, Re-Mov/DSR5, Re-Lease, Un-Hesive, and xylene for removal of 3M 5200 polyurethane caulk from fiberglass.

How We Tested

The biggest difference from our previous test was a change in technique. Instead of simply spraying the remover on the caulk surface, we first scored each of the samples every -inch and started a slight peel on one edge using a razor knife. The removers were then sprayed on the samples and left alone for 10 minutes.

Next, with firm, even strokes of a putty knife testers attempted to peel each patch of caulk away. We then reapplied and waited two minutes before repeating the effort, and logged the accumulated time for complete removal. After photographing the remaining residue, we then sprayed the samples a final time, waited two minutes, and removed the residue using a wire cup brush mounted on a drill press. The test was repeated twice for each caulk remover.

Observations

Some of marketing literature suggest that the 5200 would easily lift right off, if we did everything right. Although we didnt experience this, all of the removers made the job easier. With no remover, sawing through the caulk took triple the number of strokes and a thin layer was left behind, perfectly bonded. With xylene, the effort was reduced considerably because the caulk was slightly softened, but the bond was unaffected. Among removers, DeBond was the most effective, causing the edge to ripple and causing 40- to 60-percent of the bondline to fail. Other removers only broke about 20- to 30-percent of the bondlines.

It was also easier to remove the leftover residue. A wire cup brush on a drill removed the entire residue from all of the treated samples in about 10 seconds.

Our biggest takeaway from this test is that scoring the adhesive sealant before applying the remover greatly accelerates the bond-breaking process.

We have not tested any of these removers on polysulfides or other polyurethanes yet. Just as silicone and 3M 4200 Fast Cure behaved differently than 3M 5200 when treated, these adhesives may also react differently.

Boat Life Release

This product was somewhat effective on a wide range of adhesives, including silicone and polyurethane. It comes in a convenient spray bottle.

Bottom line: Recommended.

Easy Life Solutions Re-Mov/DSR5

Although very effective on silicone, it was only moderately effective in loosening 3M 5200. The residue was easier to remove than most.

Bottom line: Best Buy and recommend for all-around use.

North Star Un-Hesive

Moderately effective at reducing the need for scraping and cutting, but the residue was still hard to budge.

Bottom line: Recommended.

DeBond Marine Formula

The only remover that effectively broke the bond, given time and the right pre-application scoring.

Bottom line: Best Choice for 3M 5200 and worth the trip to the store.

Xylene Kleen-Strip

This product did make the caulk easier to cut through, but it did not weaken the bond.

Bottom line: Save it for paint clean-up.

Conclusions

When it comes time to remove a keel or through-hull that was bonded with 3M 5200, reach for DeBond Marine Formula. Score carefully, give it a little time, and your effort and patients will be rewarded.

Thank you for testing and the article, very helpful!

I had two 12″ x 84″ aluminum beams fully adhered to an aluminum deck. I wasn’t able to source the tested products locally but at less than three bucks a can, brake cleaner proved a tremendous value. I removed one beam with the help of brake cleaner, but used the whole can. Not realizing how effective the brake cleaner was, and being in a hurry, I continued to pry at the other beam for hours. Nothing. Admitting defeat, I picked up another can of brake cleaner and the beam came off in short order. It would be interesting to test it relative to the commercial products that were reviewed.