A safety tether keeps you safely on board, but it also comes with its own risks.

Previously, we investigated jackline materials (Jackline Materials Evaluation, Practical Sailor, November 2016), testing both common materials and commercial products. When redesigning a new tether, tester Drew Frye wanted something that fit his boat-very short for the side decks, but long for the broad decks and cockpit of his catamaran.

While the existing tethers on the market are fine for clipping into jacklines (the length of webbing, cable, or rope stretching the length of the boat), Frye saw a problem when clipping to a fixed point on the boat. Without the extra elasticity provided by the jackline, the tether alone absorbs very little energy. This could result in a harmful blow should a sailor get thrown to the end of the standard six-foot-long tether.

How much impact, are we talking about? Enough to break tethers. In the 1998 Sydney-Hobart race, Glyn Charles was lost when his tether parted during a rollover. As a result of this accident and some shocking follow-up tests, World Sailing (then ISAF) adopted a new drop test for tethers.

What We Tested

Searching for an ideal combination of stretch and strength in a tether, Frye tested various webbing and rope materials, as well as a fall-arresting device approved by the Occupational Safety and Hazards Administration.

Polyester webbing is the standard tether material. It is lightweight and lies flat, but it lacks effective energy absorption and is more vulnerable to UV damage because it is thin.

Rope is used less frequently because it can roll under your feet, but small diameter ropes are less troublesome. In the lab, Frye tested webbing from a lightly used production tether, one-inch climbing webbing, two sizes of climbing rope, and Amsteel, a high-tenacity 12-strand Dyneema rope from Samson.

In field testing, the 11-millimeter (mm) rope in the field turned out to be overkill. It was heavier, the larger diameter rope rolled underfoot, and it didnt absorb as much energy as other options. The 8.5-mm climbing half rope better met our targets for energy absorption. Typically used in tandem with another identical rope when climbing, 8.5-mm half rope is rated for the same minimum energy absorption (but more drops) as a standard webbing tether. It cushions falls well and is barely noticeable underfoot.

Often sailors believe that the elastic feature on some tether webbing will absorb shock. In fact, this elastic is designed to retain slack. Any shock absorption is noticeable only at very low loads. In our experience, the elastic lasts only a few years, while nylon climbing rope (stored out of the sun) keeps its stretch for decades. The 8.5-mm climbing rope we tested, only recently retired from climbing use, was 15 years old.

Climbing rope has drawbacks, though. Its tight cover, meant to reduce snags on rocks, makes it nearly impossible to splice. Eyes at the end are most often sewn, but this requires special equipment and load testing. However, the specified break strength for these ropes includes the use of a knot, so knots are perfectly suitable. Here are three knots we like-a buntline hitch, a figure eight on a bight (also called a figure 8 loop), or an overhand noose (also known as a poachers knot). If webbing is used, a water knot is the only option. Weve had positive results with sewn rope splices and sewn webbing, and if you have the marlinspike skills and are willing to do your own drop testing, you can create a rugged stitched tether. However, as with jacklines and harnesses, we do not recommend do-it-yourself stitching in safety tethers. Instructions for tying these knots can be found in most knot books or at websites such as Animated Knots (www.animatedknots.com).

How We Tested

In all, this report represents about seven years of experimenting with custom tethers, both in the lab and on the boat. To supplement our control tensile strength tests in the lab, we drop-tested some sample tethers, collected third party data, and cross-checked it with our own. We then compared the data to existing standards, looking at impact force, energy absorption capacity, and strength. We also sailed with the tethers, adjusting lengths, inserting shock absorbers, and changing end clips. Testing took place on a 34-foot catamaran and 27-foot monohull.

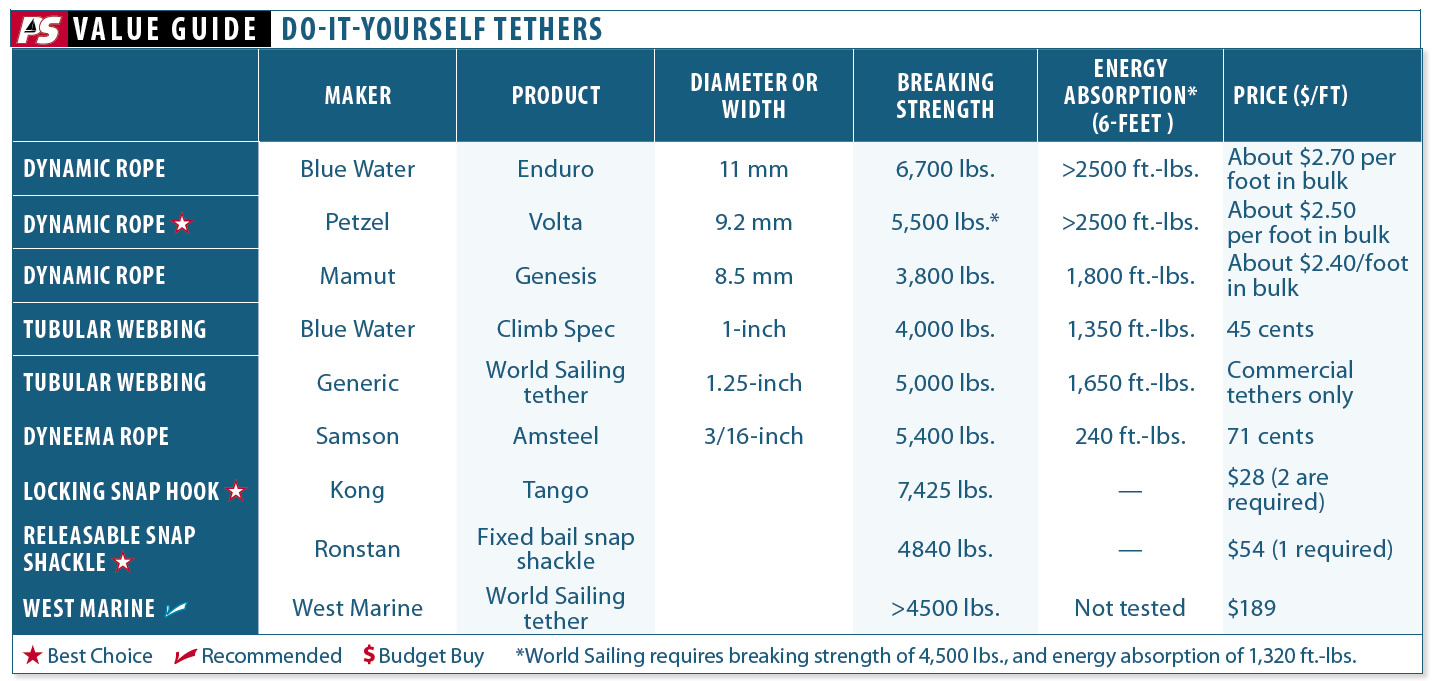

In the lab, each sample was pre-stretched twice to 1,000 pounds to eliminate construction stretch and simulate use. They were then allowed to rest for a day before slowly being stretched to 4,500 pounds-the minimum strength for fixed tether anchors set by World Sailing, the sports governing body for racing sailing-or until the tether broke. The 8.5-mm climbing rope (3,850 pounds breaking strength) and 1-inch climbing webbing (4,100 pounds breaking strength) failed slightly below the standard. The tether webbing (4,700 pounds breaking strength), exceeded the standard. Two samples, the 11-mm climbing rope (6,700 pounds manufacturer specified breaking point), and 3/16-inch Amsteel (5,400 pounds manufacturer breaking point) also exceeded the standard.

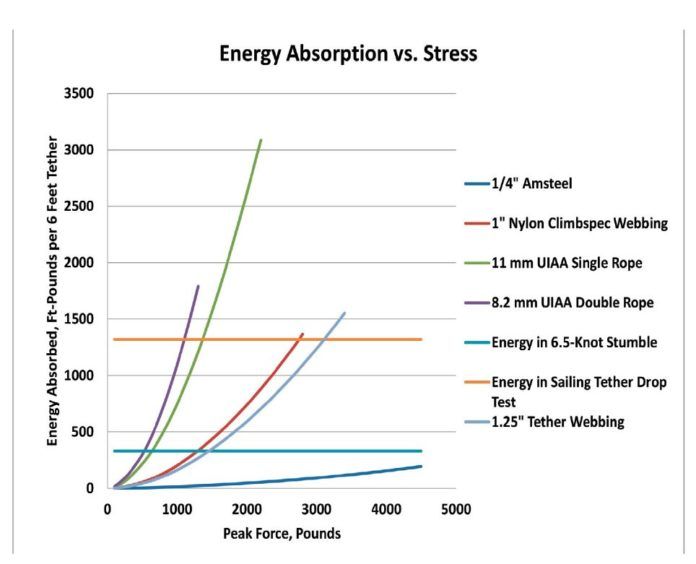

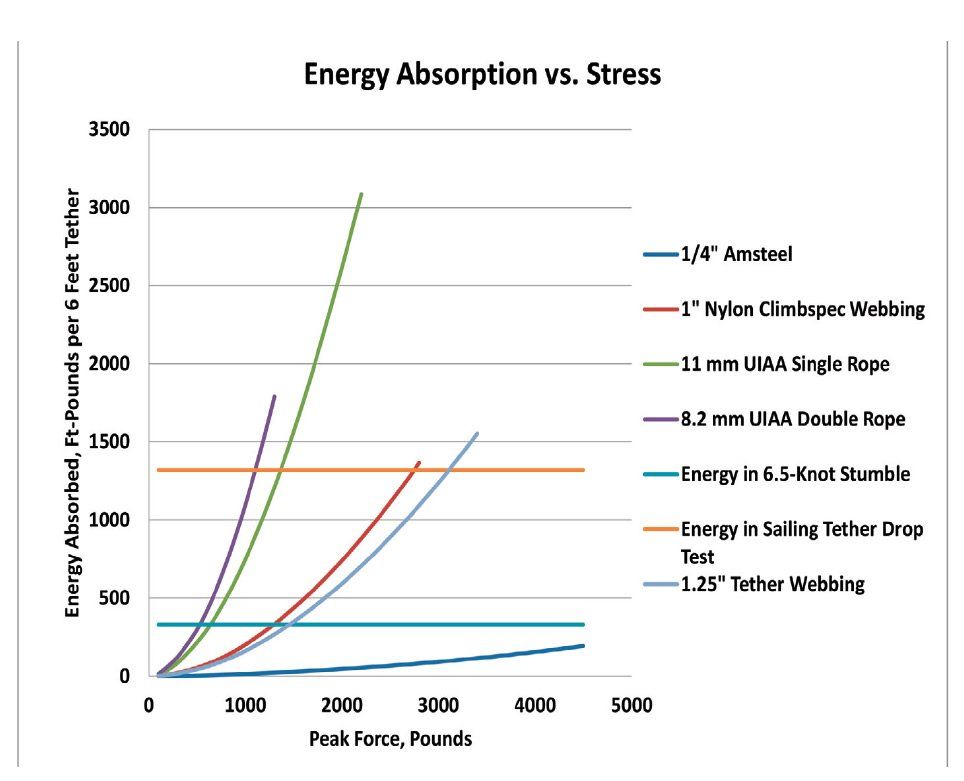

In the most simple terms, a tether absorbs energy of a fall the same way a bungee cord absorbs the bungee jumpers energy-by stretching. So during the lab test, we paid close attention to elongation. By applying bit of calculus to the elongation and tensile strength data, we were able to calculate how much energy was absorbed by each tether material.

However, the energy absorption values calculated through this type of slow-rate testing can be misleading. Based on what we know from other tests, we would expect the samples to absorb 66 percent less energy during an actual drop test, which is a more accurate simulation of what can occur at sea.

World Sailing, the governing body of racing sailing, calls for dropping a 100 kilogram dummy two meters (ISO 12401) for an adult tether (see adjacent table). The reference for this test is mountaineering rope with 8 percent stretch.

Is the sailor ever going to fall the full two meters? Probably not, but even a two-foot tumble forward at 6.5 knots can be painful. The energy for a 175-pound person hurled forward can exceed 300 pounds: 175 pounds x 2 feet = 330 foot-pounds [E=1/2MV^2, x (175 pounds/32) x (11 ft./s)^2]. Using an 8.5 mm climbing rope and a typical sailing harness, the rope absorbs the energy and the sailor is unharmed. However, with a less elastic webbing tether (or worse, a stiffer Dyneema tether), the impact would be between 600 and 1,000 foot-pounds, possibly enough to result in an injury, depending on how effectively your harness spreads the load on your torso.

For comparison, according to U.S. military standards, the maximum opening force of a parachute on a full body harness should not exceed 1,200 pounds force. In a sailors chest harnesses, the threshold for injury is much lower (just a few hundred pounds can crack a rib).

Yates Screamer

Familiar to climbers, Yates Mountaineering developed a simple energy absorber consisting of webbing folded and sewn in such a way as to rip open at a steady force. They have become the basis to industrial fall protection standards world-wide, well-proven for construction workers wearing full body harnesses. However, the force required to activate them is just too high for a standard chest harness, over 500 pounds. In addition, they are impractical because they are effectively single-use.

Bottom Line: Screamers are worth a special mention (if only to inspire armchair inventors), but they are not well suited to sailors.

ISO Certified Tether Webbing

We tested a section of webbing taken from a used commercial tether (World Sailing certified) that had suffered a minor cut during use. It met the standard, and the stitching appeared to be suitably strong, based on Practical Sailor testing. However, the stretch profile and resulting mediocre energy absorption would pack a wallop if you fell hard against it. It delivered 1,000 pounds for a minor stumble and about 2,700 pounds during an ISO 12401 drop, certainly enough to cause serious injury.

Bottom Line: We recommend only tethers manufactured after 2000, complying with World Sailing standards and the ISO 12401 drop test.

Bluewater 1-inch Climbspec Webbing

Ubiquitous among climbers and proven reliable, Climbspec webbing nevertheless falls slightly short of the World Sailing strength standard. It will sometimes pass the ISO drop test, and sometimes fail, although failures are very rare. A more serious risk is that a standard 6-foot tether would be too long for a small boat. It can stretch so much that the sailor will go over the side.

If you want to use a shorter auxiliary tether for a specific station, this Climbspec will serve reliably. When tying, make the end loops with an overhand loop, well tightened and with the tails sewn down. Do not try to sew these; PS testing determined that even the best sailmaker sewing is generally no better than a good knot.

Bottom Line: Even though these do not meet the World Sailing standard, the ability to fit custom lengths make them acceptable for short tethers.

Yale Amsteel

Unless you want to be locked down on a very short leash, Amsteel is not a good choice. With virtually no stretch, the impact force is simply too great, equivalent to landing on a brick wall. The only energy absorption is from your ribs bending. In the event of a serious blow, either you or the anchor point will break before the energy is absorbed.

Bottom line: Not a good choice for tethers

BlueWater Enduro 11 mm climbing

Capable of absorbing any conceivable fall at a force you can probably live with, 11-mm climbing rope seems like a smart choice. But it is older technology (the rope tested was over 10 years old and retired from climbing), fat underfoot, and bulky.

Bottom Line: Okay, but today, there are better choices.

Petzel Volta 9.2 mm Climbing Rope

Though we did not test this specific rope, we field tested other 9-mm size ropes. This has been thoroughly testing under climbing protocols and represents the best lightweight single rope. The 9.2-mm size minimizes under-foot rolling, the “catch” is soft, and it dramatically exceeds all World Sailing and ISO requirements. We just wish this kind of performance was available in webbing.

Bottom Line: Recommended for those that need longer tethers. This one wont break you in half.

Mamut Genesis 8.5-mm Climbing

With more energy absorption than required by the World Sailing standard, light weight, and reasonable bulk, this is the favorite on our test boat. We took dozens of stumbles and falls against these tethers while testing drogues in strong conditions, and our ribs really appreciated the non-bruising, soft catch. A good long stumble results in a reasonable 500-pound stopping force, and the World Sailing drop test yielded a maximum of 1,100 pounds, which is survivable. We miss the elastic retaining sleeve that pulls up the slack on many popular sailing tethers, but appreciate that our DIY tethers are 25 percent lighter without it.

Bottom Line: We stop short of recommending 8.5-mm climbing rope only because the tensile strength may be below the ISO minimum.

Non-Compliant Tethers

There are many tethers still on the market that do not meet World Sailing requirements or the ISO 12401. Some refer to outdated and withdrawn standards such as EN 1095. The performance of such tethers in drop testing is not known, but our previous tests and testing carried out by US Sailing suggests most will fail.

Conclusions

Based on the results of our test, climbing rope (11 mm) easily exceeds the World Sailing standard, Amsteel fails due to poor energy-absorption characteristics, and climbing webbing is marginal. Both 8.5-mm climbing rope and tether webbing meet the World Sailing standard with reasonable safety margins. Looking closer, 8.5-mm rope transmits only about 30 percent the impact force of tether webbing. This is why climbers use it.

We are reminded of our study of snubbers. Yes, we can make something super-strong, but at the end of the day, strength comes down to the weakest link. In the case of tethers, the weakest link is our rib cage. If we are going specify webbing tested to 4,500-pound tensile strength, our ribs and spine will receive very harsh treatment in a long stumble. Alternatively, we can chose climbing rope, a proven material designed for absorbing impact, and be assured that neither our ribs or spine will ever see a force over 1,000 pounds.

Tether length is critical, but there is no one-size-fits-all approach to length. On smaller boats the standard 3-feet/6-feet dual tethers are too long. In our view, 2-feet/4-feet is more practical. On our test catamaran, we found 2-foot/8-foot length to be a better fit.

Certified climbing half ropes (7.5- 8.5-mm) easily meet the energy absorption requirements, but many fall short of the breaking strength requirement. One-inch climbing webbing fails both the strength and energy requirements. Dyneemas lack of stretch makes it a poor choice.

In the end, we found only two types of tether materials that consistently meet the World Sailing drop-test standard:

- Purpose-built 1-inch polyester webbing certified to meet ISO 12401;

- Climbing ropes that meet the International Climbing and Mountaineering Federation standard for single dynamic ropes (typically 9.2-11mm).

Although the chandlery-variety commercial tethers meet all the requirements, they produce a very hard jolt in a fall and are not available in custom sizes.

We hope this report will encourage tether makers to explore the use of lighter materials and materials designed to absorb the shock of a fall. While a short, unyielding tether-to-anchor connection may serve the racing sailor well, a longer, stronger, yet forgiving tether material can be better suited to the specific needs of the offshore sailor.

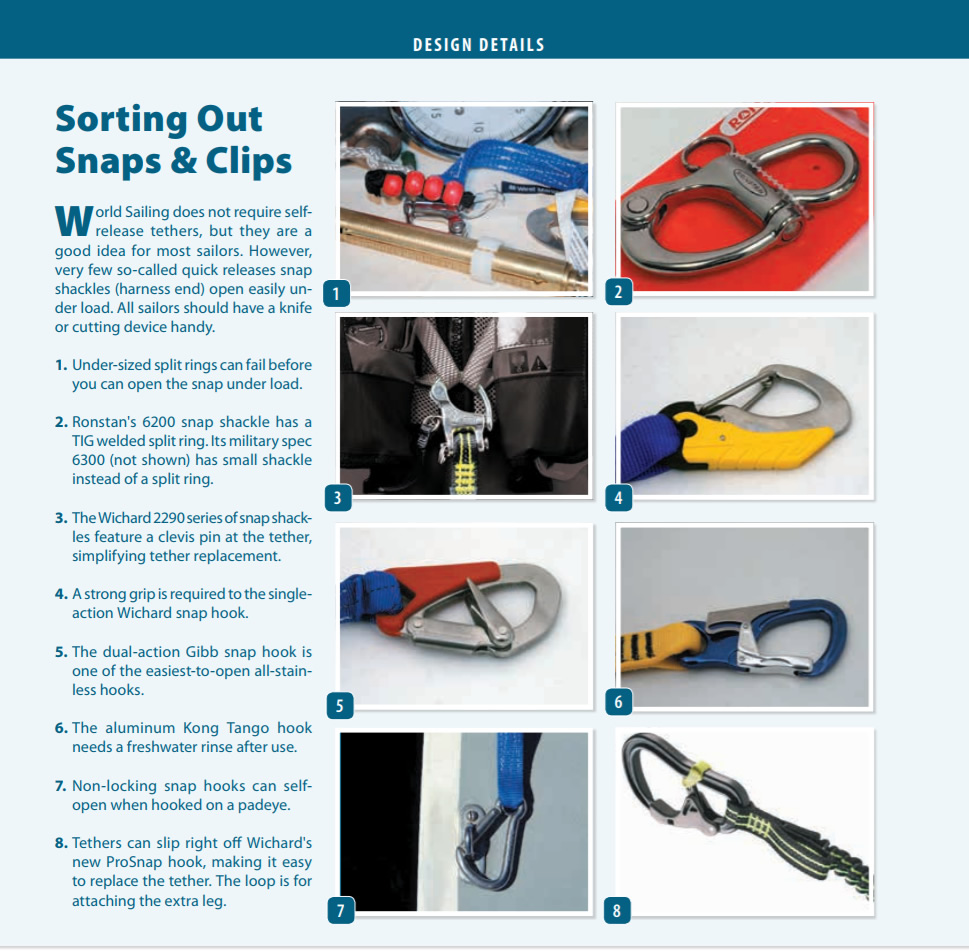

World Sailing does not require self- release tethers, but they are a good idea for most sailors. However, very few so-called quick releases snap shackles (harness end) open easily under load. All sailors should have a knife or cutting device handy.

- Under-sized split rings can fail before you can open the snap under load.

- Ronstan’s 6200 snap shackle has a TIG welded split ring. Its military spec 6300 (not shown) has small shackle instead of a split ring.

- The Wichard 2290 series of snap shackles feature a clevis pin at the tether, simplifying tether replacement.

- A strong grip is required to the single-action Wichard snap hook.

- The dual-action Gibb snap hook is one of the easiest-to-open all-stainless hooks.

- The aluminum Kong Tango hook needs a freshwater rinse after use.

- Non-locking snap hooks can self-open when hooked on a padeye.

- Tethers can slip right off Wichard’s new ProSnap hook, making it easy to replace the tether. The loop is for attaching the extra leg.