It can be a rust stain caused by a loop of chain that spent the winter lying on a sail. Perhaps a bird crawled under the sail cover and built a nest, pooping on the sail for weeks. Either way, cleaning a laminated sail presents a particularly vexing problems, since mildew likes the adhesive that bonds the material, resulting in a stain that is sealed between waterproof layers. Some of these just look bad (rust stains), but others can slowly weaken a sail (mildew in the laminate adhesive). But in all cases, overly aggressive cleaning can make things even worse, weakening the sail more than the mildew ever would.

Stains can be removed in three general ways. They can be physically removed, dissolved, or bleached (made invisible). Each requires different chemistry and a different mindset, so it helps to understand the stain.

Most stains are linked to moisture. Good ventilation prevents condensation, so consider taking sails home for the off-season. Canvas should be treated with water repellent (see “Keeping Canvas in Tip-top Shape“). This is the single most effective way to combat lichen mildew on both the cover and the sail under it.

Three Ways to Remove a Stain

Physical Removal

Physical removal requires that the bond be broken. In the case of mildew and algae, this requires that the organism be killed and for some time to pass. Borax, oxygen bleach (sodium percarbonate or sodium perborate), chlorine bleach (sodium hypochlorite), and quaternary amines (benzalkonium chloride and others) are all effective if given a soaking period. The required dose is not very high, so more is not better. Sunlight works on mildew, though very similar looking black algae are not killed by UV (unless the mildew truly grew in the dark, consider that it might actually be algae).

Surfactants—including both organic soaps and detergents, and inorganics such as trisodium phosphate (TSP), baking sodas and borax—help by breaking static bonds and emulsifying grease. Again, soaking time helps, followed by gentle agitation. More effective and less damaging, a little light work with a brush, with the sail laid out on a non-abrasive surface, also works. But remember that stains that are between laminate layers or deep in a seam will not be helped by scrubbing.

Dissolving

Dissolving works best on rust, corrosion and metals stains. The trick is to reduce the pH far enough to dissolve the metal oxide without damaging the cloth. Nylon is vulnerable to strong acids, literally dissolving before your eyes in battery acid, so nothing with a pH of less than 3 should be used. Polyester and other fabrics are less vulnerable, but we like to keep the pH above 3 because nylon thread can always sneak in.

It is always better to soak for longer rather than to use stronger chemicals, since the cloth is not affected by long soaking times at a safe pH, but the stain will slowly vanish. Some products contain chelating agents (EDTA and its relatives) to help dissolve and suspend metal at less acidic pH. The pH values for common cleaning acids such as hydrochloric acid (sold as muriatic acid), oxalic acid (Ospho), acetic acid (vinegar) and lactic acid (CLR brand) can vary by concentration, so if you are going to use an acid cleaner, you may have to dilute it further. Here are the pH levels of common acids used for cleaning (note that the acid concentrations indicated by percentages can vary by product):

Hydrochloric acid (3% acid), diluted with water 20:1, very low pH

Oxalic acid (100% acid), diluted with water 20:1, pH 2-3

Acetic acid (vinegar, about 4-6% acid), used undiluted or diluted with water 10:1, pH 3.3-2.4

Lactic (CLR brand acid is about 15%), diluted with water 10:1 to 20:1, pH 3.5-3.0

Bleaching

Bleaching is a reaction where the reactive chemical (hypochlorous acid in the case of chlorine bleach, peroxide radical in the case of oxygen bleaches) changes the chemical structure of the stain to where it no longer absorbs light, which is what gives it the color. Often, the contamination remains in place, but you simply can’t see it. In the case of laminate sails, there is little hope or removing mildew from between waterproof layers—anything that could do that would leave the sail in ruins. However, we can kill the mildew and then make the remains disappear, which is just as good. The mildew has stopped eating the sail, and we don’t have to look at the stain.

What is required is an active ingredient that can permeate through the thin laminate without damaging the cloth or adhesive. What is the most effective ingredient? Oxygen bleach—like Oxiclean—generates an uncharged radical that can permeate through the film faster than the larger hypochlorous or borate ions. Also, it is less aggressive to the fabric than bleach. While properly diluted bleach (no stronger than laundry recommendations) is safe for polyester, Spectra, and Dyneema, it weakens nylon and should be avoided. Chlorine bleach is Kryptonite to Kevlar and all aramids. In testing, exposure to a 30 percent solution of household bleach for 10 minutes can reduce the strength by 70 percent, destroying the sail. Even worse, residue becomes trapped within the laminate and destroys the Kevlar over time.

Permeation Time

Permeation is a slow process. It still takes 15-30 minutes for the active ingredients to reach stains inside laminates, and more time to do their work. Warm water helps. Molecules move faster, reactions are faster, and specific to peroxide-based cleaners, they are more effective the hotter the water is, though most have been formulated with tetraacetylethylenediamine (TTEA), which lower the effective temperature to about 105 F (hot-tub temperature). Increasing concentration makes little difference, so it is always better to substitute time for excess concentration. However, there is a practical limit to time. Like epoxies, oxygen bleaches are reactive and after 3-8 hours they become spent. In fact, the active ingredient in oxygen bleaches is not stable in water and any liquid product that claims to include Oxiclean are slightly misrepresenting the facts; they contain enzymes, but no percarbonate or peroxide compounds. They are not stable once dissolved in water.

Residue

A final thing to consider is the effect of any residue. Even after rinsing, both laminates and resinated cloth will retain some of the cleaner. It wicks its way deep inside during the soak, and even a vigorous rinsing cannot remove chemicals from behind waterproof layers. First, never exceed recommended concentration. Second, favor cleaners that leave residue that will serve some positive function; borates and BAC-based algaecides, for example, retard mildew growth. Finally, avoid cleaners that contain biodegradable organic components that may become mildew food. Most liquid laundry detergents have this failing and actually encourage mildew regrowth.

Soak, Scrub or Machine?

A machine is always wrong, no matter how gentle. A cycle is surely equivalent to dozens of hours of flogging and is sure to break down the resins, fatigue Kevlar fibers, and separate laminates. Some services use floors scrubbers, not much different from carpet cleaners with the vacuum turned down. They save time, but they can damage glue on sail numbers and tell tales. You can do the same by hand, and may need to for small spots, but should obviously be gentle. Worst of all, the chemical does not have time to work.

Finally, there is soaking. This takes time, but if the chemicals are properly selected and diluted, soaking is harmless to the cloth and effective. First, rinse the sail and examine for wear. Then spot-treat for rust or grease. Then soak in oxygen bleach. This is a required step for mildew and brightening.

Drying

Because the simplest way to dry a sail is to hoist it, we suggest not cleaning sails when the boat is in storage, but rather when they can be put back on the boat. Alternatively, you may have a dry place you can drape the sail. Putting a sail away wet is an excellent way to restart the mildew cycle.

A stain is not going to hurt anything. Despite ubiquitous statements to the contrary, we failed to find any concrete evidence that mildew and light staining/dirt damages sailcloth. On the other hand, stories abound of sails ruined by attempts to make them white again. We watched a guy scrub a sail with bleach until it was so weakened he put the scrub brush right through it. So long as you have killed the mildew (oxygen bleach or borax), simply learn to ignore it. Sails are the main engine of the boat, not a fashion accessory.

What We Tested

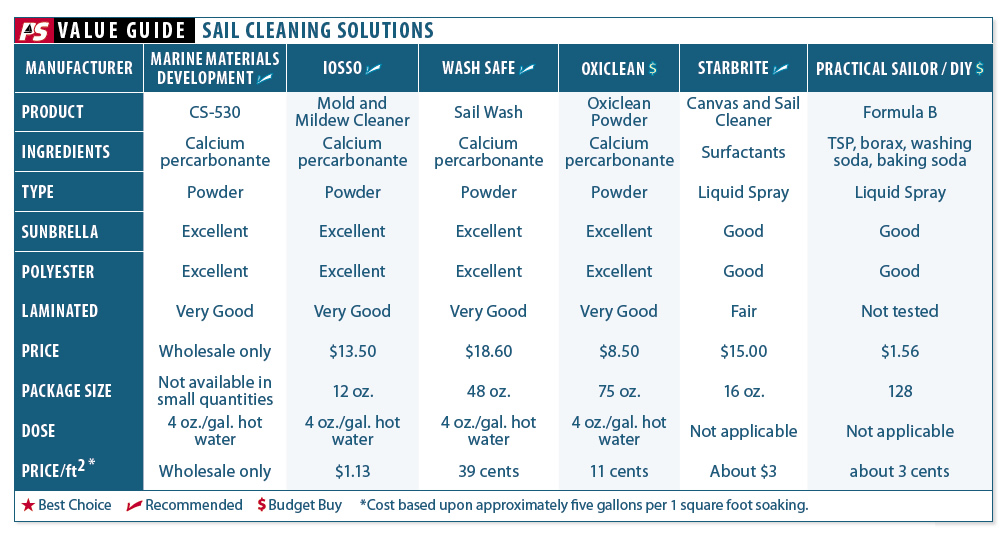

For cleaners, we tested CS-530 from Challenge Sail Cloth, Oxi-Clean Powder, Sail Wash by Wash Safe, Mold and Mildew Cleaner by Iosso, a homemade concoction we call Formula B, and Star Brite Canvas and Sail Cleaner.

How We Tested

Our mainsail became the unfitting home to several families of birds over the years. Those spots needed cleaning. We also recovered some perfectly nasty Sunbrella from the recycle bin, which provided a nice assortment of mildew and rust stains. Finally, we tested a laminated sail with mildew between the layers. We sectioned off each test material (sail or canvas) and cleaned sections with each material, diluting, scrubbing and soaking according to the directions.

Observations

Salon Cushions

Our first big project was cleaning the salon cushions of our 20-year-old catamaran. When they were last cleaned we can’t say, but for the 10 years we’ve had the boat, we’ve had kids running all over, spilled food and sunscreen, put our feet up, and sweated all over them.

We sectioned them off and went at them with a scrub brush and each of the sail cleaners in sequence, scrubbing vigorously but briefly, allowing to soak for two hours, rinsing liberally with a hose, and then extracting the liquid with the upholstery attachment on a carpet cleaner. Troublesome spots were re-treated. In the end they all came equally clean.

Some spots went deep into the foam. As the stain was removed, more would migrate to the surface, requiring repeated spot cleaning over a 36-hour period. This was not difficult, only time consuming.

And yet at this point the covers were not quite bright. But all was not lost. We learned you should quit when the canvas is nearly clean. It seems that the oxygen bleach weakens enough bonds that a half-day in the sun can often finish the job to perfection. They need drying time anyway, and the sun will safely finish your work.

Sail

We then tackled a sail that had been a birds nest for a few weeks. We tried Formula B and Star Brite Canvas and Sail Cleaner; both removed the surface dirt, but none appreciably affected the underlying stains. We then attacked the stains with CS-530 and Oxi-Clean, using procedures similar to those described for the cushions.

Winds were very light and on the bow, the sail is full batten and does not flog, so we scrubbed the stains right on the spars, hoisting and lowering as needed for access. In all cases, the stains were greatly reduced within two hours, and then vanished completely after several days exposure to the sun while sailing. Again, the lesson is that UV finishes the job, so quit when you are about 80 percent of the way there.

Taffeta/Mylar/Kevlar Sail

Finally, we sliced a mildewed section of an old taffeta/Mylar/Kevlar sail into squares and treated them according to the instructions. We did not scrub these, as the material would not stand it, and the results were less than perfect. But they were far better than surfactant cleaners, without the vigorous scrubbing. Again, sunlight helped, and the final result should satisfy.

Product Summaries by Type

Some of the products contain percarbonate, and by releasing hydrogen peroxide, remove stains chemically. These also contain surfactants. Others contain surfactants only.

Percarbonate-Based

We were impressed by all of these but could not determine real differences in performance between them. All are powders and all require 2-8 hours to work. CS-530 Mold and Mildew Cleaner, Sail Wash, and Iosso Mold and Mildew Cleaner all performed well and are recommended. In our view, however, you can do just as well using Oxi-Clean Powder, which is cheaper and possibly already in your laundry room.

Bottom line: Percarbonate-based cleaners are safe and effective when used as directed. You don’t have to buy a specialty cleaner to get the job done.

Surfactant-Based

For a quick cleaning, with allowing soaking time, these perform about the same as percarbonate-based cleaners.

The homemade Formula B (1 quart hot water, 1 tablespoon baking soda, 2 tablespoons washing soda, 2 tablespoons Borax, 2 tablespoons TSP) is an effective mildewcide with some preventative properties. However, it is not going to penetrate within laminates. It requires a little more pre-soak time than the Star Brite product (give it 10 minutes to work), but the results were similar.

Star Brite Canvas and Sail Cleaner is a good solid fabric cleaner. It removed what was on the surface but had limited effect on stains. Because it contains glycol ethers, we are not sure it is suitable for all laminate sailcloths.

Bottom line: Star Brite’s Canvas and Sail Cleaner is great for quick clean-up of surface dirt. For the budget conscious with a little more patience, Formula B is our Budget Buy.

Cleaning Services

We have not used any cleaning services, although we have received feedback over the years from readers. Most of the users were satisfied, some expected something better, and the time required varies. All services will inspect and offer repairs. These may be required before they will risk washing them; the UV covers on some of the sails we tested were so deteriorated they would not have survived the cleaning process without damage. It is also important to be realistic in your expectations; some minor stains may remain, since the measures required to remove them might damage the sail.

Using the much-advertised LaMauney process, Sail Care cleans and re-seals the sail (using resins) to restore some level of crispness. The process does not affect the shape of the sail. They will not process laminate sails. Nylon sails are only washed. We’ve gotten mixed reviews from readers, and online comments also reflect varied levels of service. Some rave about the crisp sail they got back, others cite expensive repairs and no improvement.

Another company, Clean Sails uses a soaking process very similar to that described in this article.

Bottom Line: We don’t have enough experience to rate these services. We recommend trying some of the DIY techniques first.

Conclusions

Because stains vary, there can be no single winner. For rust stains, we like CLR. Dilute 20:1 with freshwater, soak for up to 15 minutes, and rinse. For extra measure, you could buy pH strips (at pet or pool stores) to monitor the pH, particularly with nylon. For surface dirt on polyester sails and canvas, we like Formula B; it kills mildew and leaves an inhibiting residue. For mildew and algae stains we like all of the oxygen bleach products, though CS-530 may have a slight edge in soil removal.

Just how clean did the sails and cushions come out? They were near perfect and we were stunned. The sails came clean too, after a few weeks in the sun. But we would have accepted a few stains rather than use overly aggressive cleaning methods or chemicals.

Updated prices: Iosso Mold and Mildew Cleaner ($15.99), Wash Safe Sail Wash ($21.95), OxiClean Powder ($10.99), Starbrite Canvas and Sail Cleaner ($17.49), Practical Sailor/DIY Formula B (~$2.00) (

This article was first published on 22 April 2024 and has been updated.