Some products go through the Practical Sailor wringer again and again. There are many reasons for this: Products change, new products enter the field, earlier tests were incomplete, or readers are demanding an update. In the case of this update on fiberglass restorers, all of the above apply.

We first began testing acrylic fiberglass restorers back in the early 1990s. Since then, we’ve put them through panel tests (April 2000), field tests on a white powerboat (April 1, 2004 and May 2007), and finally on a well-weathered blue daysailer (September 2008 and September 2009). This month’s report is the last update on the blue daysailer test, which was aimed at comparing how the products held up in the field.

Although this test is similar to our 2004-2007 powerboat test, it features new products. Also, we were curious to see how the high temperatures generated on a darker colored hull affected longevity. Because the test platform was an actual boat in use (see “How We Tested”), we also were able to observe how these products held up in the real world.

Why so much attention to hull restorers? Part of our interest is due to the wide range of opinions on these products. Marketing materials often position these products as “miracle cures” for aging gelcoat, and the examples of restored boats appearing on the Internet or in brochures often seem too good to be true. While user reports are generally positive, some disappointing reports also crop up on sailing forums. It is our hope that this report will help clear the air, offering a well-defined picture of what these products can and cannot do, and which ones produce the best, longest lasting gloss.

What We Tested

For this test, which began in 2008, we rounded up seven products from as many manufacturers. New to our tests were Star brite Glass Cote, Klasse High Gloss Sealant Glaze, Higley FiberGloss Restorer, and Presto Gelcoat Rejuvenator. All of the products are aimed at older boats—at least four years old—with porous gelcoat. Applying these products to new gelcoat (or well-maintained gelcoat) that still has its new-boat gloss is not only a waste of time, it might end in failure since these products need a little microscopic “tooth” for good adhesion.

Some restorer products are sold as part of a complete kit, while others are just one bottle. Three of the better performing products provided applicators—Vertglas, Poli Glow, and NewGlass2. These kits also came with a pre-treatment cleaner. Other manufacturers sell cleaners separately.

All of these products, except Presto, require five to eight coats to fill all imperfections and then build up an even shine. The products must be reapplied annually or at least every two years. The more weather—especially sunlight—they endure, the quicker they wear. Poli Glow recommends reapplying at the six- to eight-month mark in tropical climates. Re-application, in most cases, is simply cleaning the hull and “re-painting” it with the acrylic sealant. Shelf life on our top products is several years, so if you don’t use a whole bottle, you should be able to use the remainder to recoat or touch-up.

How They Work

Typically, achieving a mirror-like gelcoat on an older boat is a three-stage process: Clean, polish, and protect. As with waxes, acrylic “restorers” address the final step. They fill in microscopic imperfections and provide a clear, shiny seal to restored fiberglass. As with waxes, unless the boat owner addresses the dirt and oxidized pigments by polishing, the results will be less impressive. The aim is to achieve a uniform color and smooth surface before applying a restorer.

When waxing, the polishing step usually includes a rubbing compound and/or micro-polish like 3M Finesse-It. However, manufacturers of acrylic restorers warn that polishes or rubbing compounds may contain silicones or waxes that will interfere with adhesion. When using acrylics, you prep the hull the same way you would when you are painting a hull, and that means ensuring that the surface is free of any oil or waxes. All of the four best restorers in this long-term test come with cleaner/solvents designed to remove any surface contaminants that might inhibit the sealant’s ability to adhere.

While waxes provide a hard, lasting coat to fiberglass, the fiberglass restorers in this test consist of resins of higher molecular weight that provide a harder and more durable film than can be achieved with wax. All the longest-lasting fiberglass restorers contain of water-based emulsions of acrylic or acrylic and urethane resins. The resins are in the form of tiny droplets that are suspended in water. The products are either “painted” on with a special applicator or wiped on with a rag. It’s that simple.

When applied, the water evaporates, and the droplets flow together to form a clear film. These emulsions have low, almost water-like, viscosities and dry super-fast. They require multiple coats, but application is easy, and successive coats can be applied after only a few minutes. Typical instructions call for about five coats, with three maintenance coats each year.

Findings

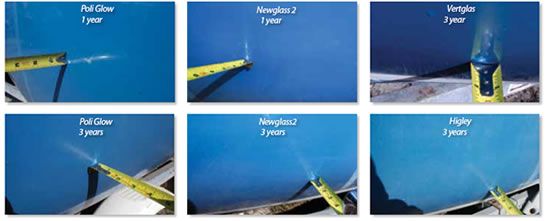

At the end of three years in the Florida sun, only two products that scored Excellent in the initial gloss comparison, Poli Glow and New Glass2, demonstrated a noticeable level of gloss retention. Vertglas, another product that did well in the first round, protected only a part of its designated section. Higley Fibergloss Restorer, a product that failed to impress testers with its gloss in Round 1, was the only other coating that remained mostly intact after three years.

This was better than we expected. All of the manufacturers recommend re-coating after one year, or sooner in a warm environment, and we completely ignored that advice. The photos on page 29 illustrate the results, and what follows are capsule summaries of the top finishers. For more detailed reports on the other products in this test, see the September 2008 and September 2009 reports online.

NewGlass2

NewGlass owner Thom Goff’s decision to increase the acrylic solids in his product by 10 percent has paid off. NewGlass2, which scored Excellent in the early rounds for gloss, held up surprisingly well. The coating remained intact up until about the two-year mark when a weekend of fender-rubbing wore away a strip along the middle. (The Poli Glow panel had a similar worn patch from rubbing on fenders on a dock.)

You can spot-finish places where this happens, but Goff says that in order to achieve the best results, you should spot finish the worn area and then coat the hull with a single coat to achieve a more uniform color and gloss. The company now offers a cleanser (Pre-Treat) to prep the area that will be restored. Pre-Treat also can remove previous acrylic coatings, although we did not find it as effective as the new spray product from Poli Glow—Poli Strip. Goff suggested softening it up with a pressure washer before applying his company’s remover.

NewGlass2 has gone up slightly in price since 2008. The three-product kit—Stain Remover, Pre Treat, and applicator—sells for $58.

Bottom line: Although slightly less glossy than the Poli Glow at the start of the test, the New Glass2 held up just as well over the long haul. It is a PS Recommended product.

Poli Glow

Poli Glow has consistently done well in previous tests. The company claims that its added UV inhibitors are what help it retain its gloss. At the end of three years, its coating integrity was slightly better than NewGlass2 and testers found it easier to apply. It was also the shiniest panel after one year, although the margin between it and NewGlass2 was imperceptible from a distance.

The kit comes with two different sizes of applicators, a 3-by-6.5-inch sponge applicator, and a 3.25-by-2-inch cloth applicator. The large one allows you to cover ground quickly, while the smaller applicator is good for tight spots.

Since our test began, Poli Glow added a third product to its line, Poli Strip, which proved very effective at removing all of the acrylic coating. It also added a coating specifically designed for aluminum, which we are still evaluating.

The company offers two pre-treatments: Poli Prep, to remove waxes and grease, and Poli Ox, to remove heavy oxidation. The Poli Ox, which is a mildly abrasive oxalic acid—similar to Bar Keeper’s Friend and other home cleaning products—worked very well at removing oxidation.

The directions were better than those provided by most other manufacturers.

Bottom line: Of our two top finishers, Poli Glow offered better performance throughout the test, but it’s most significant edge was in the overall package—including the instructions, applicators, and range of products.

Vertglas

Although Vertglas had clearly reached the end of its useful life at three years, it deserves mention here because it was one of the glossiest panels until the 18-month mark, when it began cracking and peeling. Remember, all of these products are not meant to go more than one year in a sunny climate. It was interesting to note that the portion that remained intact at the three-year mark was just as glossy as the Poli Glow panel, suggesting that this product would do well if regularly re-coated.

Bottom line: If maintained well, Vertglas will live up to expectations, but this is not enough to justify its higher price, in our view.

288

Higley

Higley Fiberglass Restoration still beaded water and preserved the color on our weathered Javelin at the three-year mark. The gloss was nominal, but its durability deserves credit.

Bottom line: Initial gloss lagged well behind the leaders, but at half the price of the other surviving restorers, the Higley might hold some appeal to budget-minded sailors.

Conclusion

Acrylic finishes are not for everyone, and the pros and cons should be carefully weighed. For most owners, we still recommend wax. However, acrylics do have certain advantages.

Application is a breeze, and the results are impressive, but the downsides can’t be ignored. If you scratch the coating, refinishing is more difficult than it is with wax—more like dealing with a chip in a varnished cap rail. And removal is a chore.

You can’t just sand these coatings away; they need to be broken down chemically, and then physically removed with a scrubber and water. If you plan to paint later, you want to make sure you’ve completely removed the product before starting. On our small boat, removing the acrylics was easier than we expected using Poli Glow’s Poli Strip. Although one 19-ounce can is supposed to be enough for a 20-foot hull, we needed about 1½ cans.

Our test boat was clearly a candidate for repainting. It was one wet-sand away from losing patches of blue gelcoat. If we had instead spent another day’s worth of prep work, and two days of painting, we wouldn’t have to worry about refinishing for another five years or more. We’d also be shelling out another $100 or so in materials. If a longer-lasting finish is what you want, see the November 2009 and February 2011 issues for our latest reports on topside paints.

In terms of initial gloss, the cheaper but more strenuous approach with conventional wax achieved nearly identical results as the best acrylics. This was more work, however, and after four months, it was time for another coat of wax. If you don’t mind a regular buff -and-wax routine, see the February and July 2009 articles on our best paste waxes, and the January and September 2010 articles on liquid waxes.

Ultimately, we were quite happy with the result. In one day we applied seven different products and 12-months later people were still stopping by the boat asking if it was for sale. Although we’re tempted to apply any of the three top finishers to the hull again, we’ll probably paint. Then again, time is a rare commodity these days.