The Best Respirators for the Boatyard

Athough falling off a ladder or cutting yourself with a sharp tool are the most common boatyard injuries, damage from the foul air we breathe is more insidious. Marine paints contain solvents that can make you dizzy at best or increase cancer risk at worst. Dust from sanding wood is usually only a nuisance, but sanding bottom paint or grinding fiberglass presents serious health risks. Fortunately, theres a wealth of industrial experience with contaminated air…

Fixing Tears in Sunbrella Boat Canvas

Sooner or later, chafe, UV rays, and sharp edges take their toll on our canvas. A misplaced screw or simple friction will eat holes in a dodger. A seam gives up, a boom rubs through the fabric, and a few snaps come loose.

Esoteric Fibers Call for Epoxy

Theres little debate over the adhesive quality and toughness of epoxy resin-just look at where its being used. We hear about its presence in crucial structures such as aircraft wings, race car bodies and high-end custom racing yachts. But it takes a little familiarity with engineering lingo to help us understand why epoxy trumps its ester relatives.

Glue-on Fasteners

Although through-bolts may be the gold standard for strength and security, sometimes drilling a hole isn't practical, or exposes foam or balsa core to water intrusion. Mounting a sump-pump to the side of the hull, attaching electrical components when the other side is either inaccessible or exposed, mounting an air conditioner on the bridge deck of a catamaran, or adding solar panels to a hard top are just a few examples of situations where a surface mounting is needed.

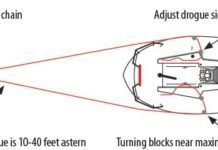

Ideal Drogue setup will require experiments

For maximum maneuverability, the control lines-one port, one starboard-should attach at the widest part of the boat. This maximizes leverage and places the effort close to the center pivot point. On a catamaran, closer to the transom works because of the wide beam, but for monohulls, attaching near the pivot point at the keel will be more responsive. For maximum responsiveness, the drogue should be as close to the transom as practical-this results in more responsive steering and minimal drag. We found the best compromise to be around 65-80 percent of the way aft, where there is still enough beam, but less risk of the control lines fouling.

What’s the Best Anode Material?

Every fall, as the hauled-out boats are sardined into boatyards, a walking tour reveals the casualties from the underwater war. Saildrives are deeply pitted and shedding paint. Bottom paint is burned near seacocks. Folding props no longer fold. Most often, these losses are blamed on the zinc anodes-or lack of them.

Measuring Anode and Cathode Degradation

The anodes were cleaned, weighed, and installed on 2-foot lengths of 3/4-inch, copper pipe (type M), which were also weighed. We hung the samples between slips in the mid-Chesapeake Bay near Rockhold Creek for one year, cleaning quarterly to mimic light use. At the end of the test period, the samples were cleaned with a plastic scraper and scrub brush, and their interiors were scrubbed with a snugly fitted multi-knotted rope. Testers gave them a light acid cleaning to loosen barnacle residue and scrubbed them again before weighing them. We also measured potential driving force and current for each anode before and after exposure. Salinity at the test site varied from brackish to seawater salty. We will be testing in full-strength salt water for a followup article.

PS Tests Adhesive Removers

Many years ago, one of our editors had an old wooden boat with lovely wooden handrails just inside the companionway that his sailing partner decided could use new varnish. The original coat, which was peeling around the base and worn where hands had gripped it, was sanded smooth and meticulously coated with varnish. Subsequent coats were applied according to the process that had served well for years-varnish, scuff, wipe, varnish, scuff, wipe . . . repeat.

A New Spin on Dependable Crimps and Splices

Our test focused primarily on the small-wire connections tensile strength, with and without solder, but we also looked at their durability under tough environmental conditions. We tested the pull-out strength without solder and the pull-out strength of soldered connections at 400 degrees by heating the connections in an oven to simulate overheating conditions. We tested fatigue by spinning a 6-inch length of splice wire at 650 RPM in a simple device that we called the wire-fatigue whirligig. Finally, testers soaked all samples for four months in salt water to accelerate corrosion, and then, we repeated the fatigue test.

Testing Winches with Dale

Part 2 of our winch test this month brought back fond memories of the man who helped steer me into my position as PSs skipper, the late Dale Nouse, our former executive editor who died of cancer less than a year after I took over as editor in 2005. Dale was in charge of a winch test that year. He passed away a few months later, at the age of 82-working nearly to his last day after 13 years with Practical Sailor.