Go inland from Long Island Sound about 37 miles up the historic Connecticut River and you’ll come to the town of Rocky Hill, home of Hayn Enterprises, LLC.

Hayn has stepped out with a set of new wire cable end fittings, or terminals. Designed by Petersen Stainless Rigging in England, the “Hi-Mod” compression fittings are being manufactured by both Petersen and Hayn, which recently purchased four more computer-controlled precision lathes (to go with the original one).

The Hi-Mod is said to have several improvements over the widely-known Sta-Lok and Norseman fittings. (Practical Sailor has tested to destruction these wire rope terminals, which are known to engineers as Fiege-type fittings. In a pull test of Norseman, Sta-Lok, Quick Rig, Castloc, Nicopress, swaged and rope clamps, the Norseman and Sta-Lok proved themselves superior to or the equal of all the others.)

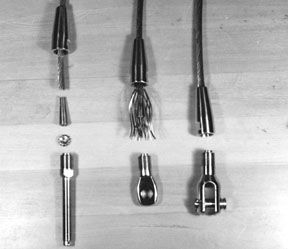

Hayn’s new Hi-Mod has a longer cone (see photo) to spread the compression load over a greater surface. The cone has a shallower angle, which increases the force that can be “ramped” on the wire as the threaded end fitting is drawn tight.

More importantly, the Hi-Mod also has a “Crown Thrust Ring,” which resembles a thick washer with slots on the edge.The slots, 12 in number, are to engage the 12 outer strands of 1×19 wire, which has one center strand with six strands surrounding it, making 19 in all.

The little washer, which fits over the seven strands in the core bundle, makes it easier to assemble the fitting. It avoids the very difficult arranging and bending of strands required with a Norseman or Sta-Lok, and keeps them orderly when the critical tightening commences. (If the strands are scrambled, what is improperly but commonly called “galling” can result from over-compressed bits of metal cold-welding into a single mass.) Hayn claims the smooth evenness of the Hi-Mod neatly avoids that possibility and also reduces the fatigue factor.

As with Norseman or Sta-Lok, disassembly for inspection or re-use (with a new cone) is easy, and the fittings are engineered to be stronger than whatever size wire they are used. (These fittings do not work with Dyform wire, which has but seven strands, one in the middle with six surrounding it.)

The Hi-Mod fitting comes in nine sizes, from 1/8″ to 1/2″, with eyes, forks or studs.

Contact – Hayn Enterprises, 800/346-4296, www.hayn.com