Every spring, there are numerous threads on the sailing forums discussing the best ways to clean ropes, mostly about dock lines. Brutal methods are suggested: power washing, soaking in a bucket of bleach for a week, scrubbing them with Spick-N-Span and leaving them on a bright concrete sidewalk to dry. Others recount experiences of ropes disintegrating in their washing machine, of washers being mangled, and adamantly insist that the only safe method is gentle agitation in a tub with the lightest touch of Woolite.

Our own interviews with technical representatives from major rope manufacturers Bluewater Ropes, New England Ropes, Samson Cordage, and Yale Cordage on this topic yielded uniformly conservative guidance. These makers have all faced claims of rope failure resulting from poor cleaning methods. They all recommend some cleaning, but they generally suggested this should be limited to a freshwater rinse. Rinsing removes salt crystals and is safe, even for an obsessive-compulsive rope-cleaner. The truth is that mildew and algae don’t weaken synthetic ropes, so cleaning green stains from your jib sheets is a purely cosmetic effort. Generally, anything but a mild rinse is best avoided for the first few years in the life of your running rigging.

Advice on How to Clean Boat Ropes from Manufacturers

In search of definitive guidance on rope cleaning (see How We Tested), we turned first to manufacturers for advice. Although the advice varied in some details, all agreed on the following points.

Wash only with a very mild detergent. For relatively new ropes, this means something like Woolite or a half-dose of a modern laundry detergent. For the first few years, ropes still contain thread coatings and lubricants from the factory that provide an easy hand, as well as offer some protection from UV radiation, abrasion, and water absorption. Washing a new rope in a cleaner touted as degreaser will harm this protective coating. After several years, when these lubricants have clearly been washed away by rain and worn off by normal use, ordinary laundry detergents at ordinary doses are acceptable. Avoid any cleaners that have a pH value below 7 or above 9, exaggerated soaking periods, or exaggerated doses. Most common laundry detergents are buffered in this pH range when used as directed.

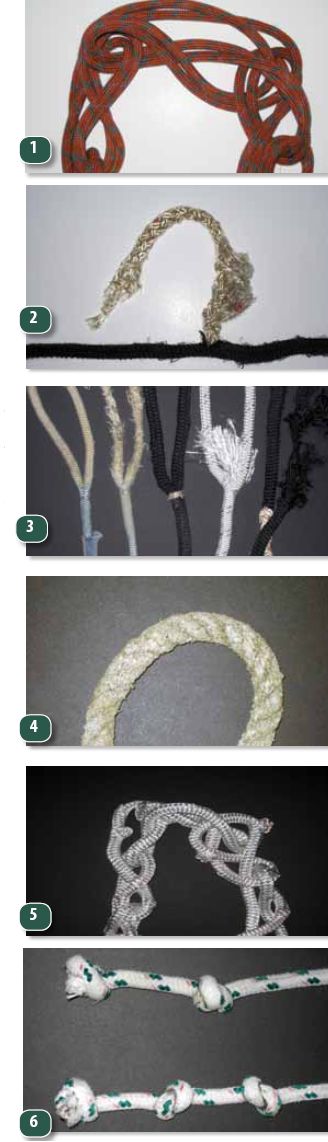

Wash on the gentlest cycle. The rope should be tightly coiled or tied in a daisy-chain, and then placed inside a pillowcase. Front-loading washing machines are recommended; an up-and-down motion is preferable to the rotary motion of most common household machines. Without coiling or daisy-chaining, a rope can turn into an impressive tangle. The pillowcase further restricts the motion of the rope and prevents the rope from wrapping around the central agitator, which can destroy ropes and break washing machines. For a video of daisy chaining, search chain sinnet (also called a monkey braid), on www.animatedknots.com.

Avoid contact with acids, bases, and solvents. Both polyester and nylon (polyamide) are vulnerable to certain chemicals, so manufacturers broadly warn against using them. However, both nylon and polyester are unaffected by most solvents. Extended exposure to certain alcohols can weaken polyester. Both nylon and polyester have some vulnerability to alkalis such as those found in strong cleaners like TSP (trisodium phosphate) or Spick-N-Span.

Nylon is particularly vulnerable to acid. Strong acids such as battery acid or muriatic acid can literally melt right through a nylon rope in a matter of minutes. Soaking for an hour in weak acid cleaners (typically based on phosphoric acid, oxalic acid, citric acid, or acetic acid) such as Lime-Away or Shower Power can weaken the rope by as much as 50 percent without any worthwhile cleaning benefits. Avoid all acid cleaners, including vinegar, and diluted acids.

Fabric softener at recommended doses is approved. However, high doses of fabric softener can weaken ropes, primarily because they prevent complete drying.

Power washing is not recommended. While it can be an effective method for cleaning marine growth from mooring pendants and dock lines, a power washer in the hands of an inexperienced operator can do significant damage. High-pressure water can easily cut through a line and do significant hidden damage. Power washing can be carried out safely by keeping the power-washer nozzle at a sufficient distance, but there is no easy way to tell whether your work is causing some hidden damage.

Bleach is not recommended by any manufacturer in any quantity. Every manufacturer has faced claims of rope failure or splice failure caused by a bleach overdose. Extended soaking in bleach solutions must be avoided.

Hot water is not a problem. Nylon and polyester are undamaged at normal water-heater temperatures (120 to 135 degrees).

Don’t dry with heat. The rope should be flaked loosely on the floor and left to dry. Nylon and polyester ropes are not typically heat-set, and there is great risk that the sheath and core will shrink differently, causing distortion and structural damage to the rope.

The following additional experience was volunteered by professional riggers:

Washing won’t make splicing easier. Old double-braid is difficult to splice, and washing doesn’t change that. Polyester remains too stiff even if treated with fabric softener.

Washing machines don’t like nylon double-braid. Nylon double-braid is subject to herniation and destruction during the machine-washing process. Never machine wash a new or nearly new nylon dock line!

Bleach is very bad (again). This one is worth repeating. Each spring, riggers are asked to re-do splices that have come loose after bleach ate the stitching and whippings that secured the splices. Without a few key stitches, a splice will be milked apart in 30 minutes of agitation.

The Marine Ropes We Tested

Several hundred feet of decrepit dock lines were collected as part of a Chesapeake Bay area marina cleanup program; most of these lines had been in place for 10 to 20 years, strung between slips, abandoned by former owners and left hanging, or dropped to the bottom. Several hundred feet of used but good condition polyester, double-braid line (New England Ropes Stay-Set) were donated by a local rigging company. All of these lines were cut up into manageable lengths and subjected to a variety of machine cleaning methods.

Some were barely dirty, while others were nearly twice their original diameter, encrusted with all manner of marine life. While in some cases we were able to recover usable line from apparent trash, in many cases old dock lines simply disintegrated during cleaning. Polyester double braid was undamaged by any machine cycle, either visibly or by feel.

Our testing was limited to nylon dock lines and polyester double-braid. We did not perform strength tests on used lines because the histories were unknown, so the results would be of little value. We also washed several lengths of new dock line from New England Rope and Samson, as we were warned by riggers that these were particularly vulnerable to damage by machine washing. We also exposed new nylon double-braid dock lines to bleach for several fixed time periods. The ropes were then sent to New England Ropes, where they were load-tested until they broke to determine the effect of bleach on ultimate breaking strength.

This project was less about collecting scientific data than about collecting practical experience about what works and what doesn’t. We also got to spend hours practicing washing machine repair. Woo-hoo! Thats testing.

More Tips on How to Clean Boat Rope

Rather than drag you through the hours of testing and washing-machine repair that our test entailed, we’ll focus on what we learned. Here are the highlights:

Carefully whip or melt the end of every rope before washing. A few whippings came off, and the mess was impressive; three-strand line often unlaid to fuzz for several feet, until the first tight coiling restricted it. Double-braid fuzzed for at least a few inches. We also proved that this fuzz and bits could effectively jam a washing machine pump. Although a pillowcase reduces cleaning effectiveness, it prevents frayed bits of rope and heavy dirt from damaging the machine.

Pre-soaking allows more gentle cleaning. If the lines are heavily soiled with marine growth or algae, presoak them in a bucket of hot water with a regular dose of mild detergent for an hour. This is safe and very effective. Agitate by hand for a few minutes at the end of the soaking period, gently apply a scrub brush to the bad spots, and dump the water. This allows a much gentler cycle to achieve the same result, and the heaviest dirt is removed before placing the rope in the pillowcase, which reduces the amount of dirt trapped in the pillowcase during washing. Do not pre-soak with harsh detergents or bleach. These stronger cleaning agents are not needed and can cause significant damage.

Use the gentlest cycle that will clean the line. No used line was damaged when washed in the pillowcase, with ordinary detergent, on the gentle cycle. Washing clothes along with the pillowcase-enclosed lines helps protect the ropes during washing. The pillow will catch any heavy soil that might stain ordinary clothing. Extremely dirty ropes will have to be pre-soaked first.

Wire ties worked well for closing the pillowcases. None our test pillowcases came open. Don’t use your best pillowcases. They will take a beating.

Secure a sock over any spliced-on shackles. Secured with a wire-tie, a soft sock protects the shackle, rope, and washer.

Learn how to daisy chain your ropes. Ordinary coils frequently came apart, resulting in damaged ropes. Daisy chains fared better. The daisy chain should be slightly tighter than for ordinary storage; not tight knots, but not so loose that it shifts excessively during washing. Six-to-eight-inch loops worked well, depending on line size and stiffness.

Never machine wash new double-braid dock lines. New England Ropes double-braid failed by herniating the core through the cover every 6 to 12 inches within 10 minutes of washing, even on gentle cycle. Sampson Ropes double-braid dock line better withstood machine washing, but one of two eye splices failed (core pulled out of the splice). Its the continuous back-and-forth milking of the cover in wet soapy water that causes the trouble, something a rope never sees in real use.

Stitch all eye splices. Many eye splices survived, even on vigorous cycles. In all cases, the surviving splices were stitched to anchor the core and whipped at the join. All failures were un-whipped splices with no core anchoring stitches.

Be careful with soft-laid three-strand rope. Soft-lay, three-strand rope failed by hockling or unlaying unless washed gently in a pillowcase. Hard and medium-lay ropes faired much better. A scrub brush combined with gentle soaking is the safest method for heavily soiled dock lines. Labor intensive, but safe. Power washing blew some older ropes apart.

Polyester double-braid withstands machine washing very well. We were not able to visibly damage any quality polyester double-braid (Yacht Braid and Sta-Set) with any wash cycle or repeated washing-even uncoiled rope. This suggests that gentle washing of polyester running rigging is quite safe.

Avoid bleach (again). We tested the effectiveness of bleach by pre-treating with bleach and by bleaching after washing. In no case was a difference observable. If there is some minor mildew or algae growing on the tail of the rope, clean that portion of the rope, and set it in the sun. In our cooperative test with New England Ropes, it was found that bleach was aggressive in removing lubricants, roughening the texture of the line, and increasing stiffness, even when applied according to directions.

Acid cleaners are very damaging. We pretreated several lines with weak acid cleaners and saw no improvement; however, the lines were visibly softened and damaged, and had less than 50 percent of their original strength. Some have suggested that you need to use weak acids to remove lime deposits within the core, but there are lime removal agents (EDTA and triethanolamine) in most detergents, and these do the job safely. None of the ropes we washed had objectionable residual stiffness.

Rope cleaners aren’t worth the expense. We tested a purpose-built rope-washing devise by PMI, used by cavers and climbing schools to clean the grit out of muddy ropes. For the average sailing rope, the device was no more effective than a rinse with a hose.

Long-term findings. What about fabric softener, water repellents, and other rope treatments? We’ve found some very interesting products, but it is too soon to report on these. Durability of the treatments over time is critical, and we need time in the field to study them. Do they wash out in the rain? Do they negatively impact line clutch or winch efficiency? Do they help lines resist freezing and improve handling? We’ve treated some running rigging with various products and will report back with our findings.

Conclusions on Washing Rope

We washed yards and yards of rope to find practical answers in the form of procedures rather than product selections. These are our bottom line lessons:

Never wash a new rope. Specifically, we learned that new double-braid dock line that is washed in a machine herniates right through the shell, that splices come loose unless whipped and stitched, and that every line is vulnerable to overly vigorous washing. Give them a light scrubbing with a brush if you must, and leave it at that.

If you must wash a rope in a machine, think twice; are you willing to ruin the rope? If so, then take sensible and proven precautions: whip and stitch all the splices or they’ll come loose, whip or thoroughly melt and fuse all rope ends, cover shackles with old socks to protect the machine and the shackle, always coil tightly or daisy chain the rope, and package the rope in a pillowcase. Skip the pillowcase and expect both rope and machine damage; we experienced both. And certainly, use the gentle cycle. If the gentle cycle doesn’t do, soak first and then scrub a bit by hand.

As for soaps, cleaners, and chemicals, we learned ordinary laundry detergents at ordinary doses are fine for older ropes (remember-you shouldn’t be washing young ropes) and an extended soak in a mild detergent really helps soften stains without risking damage. Bleach didn’t do much that the sun wont do and poses much greater risk. Acid is deadly to ropes; don’t even consider it.

When we followed these simple rules, the ropes were undamaged and results often surprisingly good.

VALUE GUIDE: Old-Line Cleaning Test

| CYCLE | NUMBER OF SAMPLES | DAISY CHAIN (D) COIL ( C ) | NYLON DOUBLE BRAID CLEANING / DAMAGE * | NYLON 3-STRAND CLEANING / DAMAGE* | POLYESTER DOUBLE BRAID CLEANING / DAMAGE* |

|---|---|---|---|---|---|

| STANDARD DOSE, TIDE HD | |||||

| Heavy Duty | 5 | C | 2 / 100% damaged Herniation and excessive fuzzing | 2 / Soft laid hockled, hard laid fuzzed and unlaid | 1 / None |

| Heavy Duty | 5 | C | 2 / 100% damaged Herniation and eye splice failure | 2 / Soft laid hockled, hard laid fuzzed and unlaid | 1 / None |

| Heavy Duty | 5 | D | 1 / One frayed at end, other undaamged | 1 / Soft laid hockled, hard laid fuzzed and unlaid | 1 / None |

| Heavy Duty | 5 | D | 1 / No damage, but fuzzed | 1 | 1 / None |

| Normal | 3 | C | 2 / Damaged; herniation and excessive fuzzing | 3 | 2 / None |

| Normal | 3 | D | 2 / No damage | 2 | 2 / None |

| Gentle | 2 | D | 3 / No damage | 4 | 2 / None |

| STANDARD DOSE OF WOOLITE | |||||

| Normal | 2 | D | 2 / No damage | Not tested | 2 / None |

| Gentle | 2 | D | 3 / No damage | Not tested | 2 / None |

| PRE-SOAK WITH STANDARD DOSE OF TIDE, BRUSH USED VERY LIGHTLY ON HEAVY GROWTH AREAS | |||||

| Normal | 4 | D | 1 / No damage | 2 | 1 / None |

| Gentle | 2 | D | 2 / No damage | 2 | 2 / None |

| PRE-SOAK WITH 1 CUP 3% BLEACH PER 2 GALLONS COLD WATER FOR 1-HOUR | |||||

| Normal | 2 | D | 2 / No damage | Not tested | 2 / None |

| *Cleaning ratings: 1=Excellent, 5=Poor |

Our testing matrix focused on four basic questions: Is the cleaning effectiveness of ordinary detergents and gentle detergents much different? Were there any differences if we used vigorous or gentle cycles? Could we protect the rope from damage by coiling and packing it in pillowcases? What effects do harsh cleaners have on the ropes?

Cleaners: We didn’t see measurable difference in cleaning effectiveness between Woolite and Tide. Everything stated in the lessons learned regarding Tide applies to Woolite.

Cycles: It became pretty obvious as we ran through the batches, that unless a gentle cycle was chosen, we risked serious rope damage unless every precaution was taken. The data clearly reflect this. The cleaning wasn’t much better on vigorous cycles when compared to ropes that were presoaked and daisy-chained. We eventually stopped vigorous cycle testing because of the damage it caused to the ropes and the washing machine.

Packaging: Pack all ropes in old pillowcases. We tested daisy-chained and coiled ropes side-by-side; daisy-chained ropes consistently came out cleaner and with less evidence of core slippage. When washing heavily soiled ropes, the pillowcase would interfere with cleaning since the heavy dirt couldn’t escape; if you have lines that are severely encrusted with marine growth, pre-soak, gently brush off the heavy growth, and then wash on the gentle cycle in a pillowcase. The effectiveness of pre-soaking was remarkable and the risk of damage to a sound rope when using this approach was very low.

Aggressive Chemicals: Stay away from strong cleaning chemicals. New England Ropes donated lengths of dock line, which they pre-stretched to simulate initial use. We then soaked them in a number of different bleach solutions, simulating real practices, rigger horror stories, and manufacturer horror stories. Although the damage wasn’t catastrophic, it was material. One practical problem encountered is that rinsing bleach from half-inch thick rope is very difficult. It was never clear how much bleach we left in the ropes, in spite of repeated and vigorous rinses. We also noticed that bleach simply didn’t do much that the sun wouldn’t do. Aluminum and grease stains did respond to bleach, as we saw in the polyester halyard we washed and bleached. As for acids—some suggest weak acids to remove lime deposits—we found battery acid would eat nylon rope in half in minutes, not hours, and weaker acids were still more damaging than bleach.

The importance of carefully whipping any eye-splices became apparent early on in the testing.

Fully 70 percent of our test samples, including new and used line from New England Ropes and Samson Ropes, experienced failure of pre-spliced eyes (see Splice Failure table). The buried portion of the core worked its way out of the main line and into the eye, where it carried zero load. In some cases, these failures were scarcely visible, while in others, the tail was exposed.

Since it takes only a few minutes to stitch a splice. Why risk the chance of failure?

We also noted that new braided lines tended to herniate (see New- Line Cleaning table). The continuous back-and-forth milking of the cover in wet soapy water is what causes the trouble, something a rope never sees in real use.

LINE CARE: New-Line Cleaning Test

| CYCLE | SAMPLES | DAISY CHAIN (D) COIL (C) | DOUBLE BRAID DAMAGE NEW ENGLAND ROPES | DOUBLE BRAID DAMAGE SAMSON |

|---|---|---|---|---|

| STANDARD DOSE OF TIDE HD | ||||

| Gentle | 2 | D | Herniated core through cover every 6-12 inches | 100% of eye splices failed (core puled out) |

| Gentle | 2 | C | Herniated core through cover every 6-12 inches | 50% of eye splices failed (core pulled out) |

| *Cleaning ratings: 1=Excellent, 5=Poor |

LINE CARE: Splice Failure

| CYCLE | SEWN AND WHIPPED | SPLICED ONLY |

|---|---|---|

| Gentle | No failure of 6 samples | 3 of 4 samples failed |

| Normal | No failure of 6 samples | 4 of 4 samples failed |

| Heavy duty | No failure of 6 samples | 4 of 4 samples failed |

| All ropes washed in daisy chain, new rope |

We investigated the effects of the commonly used, yet potentially highly destructive bleach on rope strength. Samples of New England Ropes half-inch nylon dock line were pre-stretched 10 times to about 10 percent of rated strength (850 pounds) to simulate initial use. They were then treated with bleach, as presented in the table above. Samples that were treated more than one cycle were allowed to dry and set for 24 hours in a dry state before the next cycle. The samples were then pulled 10 times to about 50 percent of rated strength (4,250 pounds) before being pulled to failure.

Simple washing reduced the strength of the line 7 percent; the removal of spinning lubricants likely reduced the strands’ ability to equally share the load. Bleach, whether applied as concentrate for 20 minutes or as an overnight soak, reduced the line strength an additional 4 percent. Most destructive was repeated bleach and dry cycles, reducing strength up to 18 percent beyond simple washing. We presume this is because it was very difficult to completely remove the bleach at the end of each cycle—ropes are very thick in comparison to clothing—and as a result, the bleach dried in place, increased in concentration, and did more damage.

Samples of each type were retained for testing in one year. Will additional time, just sitting and aging, make a difference? We’ll let you know.

Riggers report bleach-destroyed lines every spring. It seems probable that older lines may be more vulnerable to damage than new line.

LINE CARE: Bleached Line* Breaking Strength

| SAMPLE | BREAKING LOAD |

|---|---|

| Control | 10,793 lbs. |

| No bleach | 10,000 lbs. |

| 16:1 dilution beach for 20 minutes, rinse, dry. 2 repetitions | 8,476 lbs. |

| 16:1 dilution beach for 20 minutes, rinse, dry. 6 repetitions | 8,232 lbs. |

| 16:1 dilution beach for 20 minutes, rinse, dry. 1 repetitions | 9,695 lbs. |

| Undiluted bleach for 10 hours, rinse, dry. 1 repetition | 9,573 lbs. |

| *1/2 inch New England Ropes dock line pulled to 850 pounds to simulate initial use and pulled to 4,250 pounds before pulling to failure. |

I highly recommend using a mesh laundry bag instead of a pillowcase. The mesh allows water to circulate and crud to escape.

1. I use mesh laundry bags instead of pillow cases. Works just as well, and water can flush in and out.

2. Unless really soiled, just using fabric softener gets the salt and basic grime out, in my experience. If I use soap, I need to add at least one rinse cycle or a washing without soap to really get the line back.

3. Re your comments on whipping splices. I have never decided whether it is better to whip a splice at the throat (hold splice in one spot, but negates some of the Chinese-finger-puzzle effect, or to whip it toward the end of the buried portion, but that allows movement at the throat. Which is better?

So how do you clean a mooring line that is full of weed and shel growth then? This can happen within 2 months in the Caribbean.