Your dock neighbor just switched out her old 12-volt lead-acid batteries for lithium-ion batteries. Should you? The lithium solution will be more expensive, but there are benefits, and we will offer some additional lithium background as we dig into this highly charged subject.

What type of boat is a good candidate for a lithium-ion power system? It depends mostly on how your boat is used and how often. If you plan to leave the dock and stay away for a long time, using solar, wind, or alternator to charge your batteries, lithium is a great option. If your boat is on a mooring, away from shore power for longer stretches, has higher electrical loads but no generator (think air conditioning), has limited space, or is hybrid powered, lithium has benefits here too.

If your boat is older and you plan to refit its electrical system to modern standards, an upgrade to lithium might make a lot of sense. Whatever the case, be sure that you take a systemwide approach and make the effort to understand the care and feeding of these batteries.

THE LITHIUM ADVANTAGE

For the same or possibly even smaller group size battery, lithium provides higher energy capacity, lighter weight, and almost four times the lifespan than their lead-acid counterparts. They can utilize more of their power potential without cell damage, charge more efficiently, and do not take a “memory” if charged without first being fully discharged, like common deep-cycle batteries. Lithium batteries don’t leak or discharge toxic fumes while charging, and they can undergo thousands of charge-discharge cycles, while lead-acid batteries may only be able to pull off a few hundred in an ideal setup.

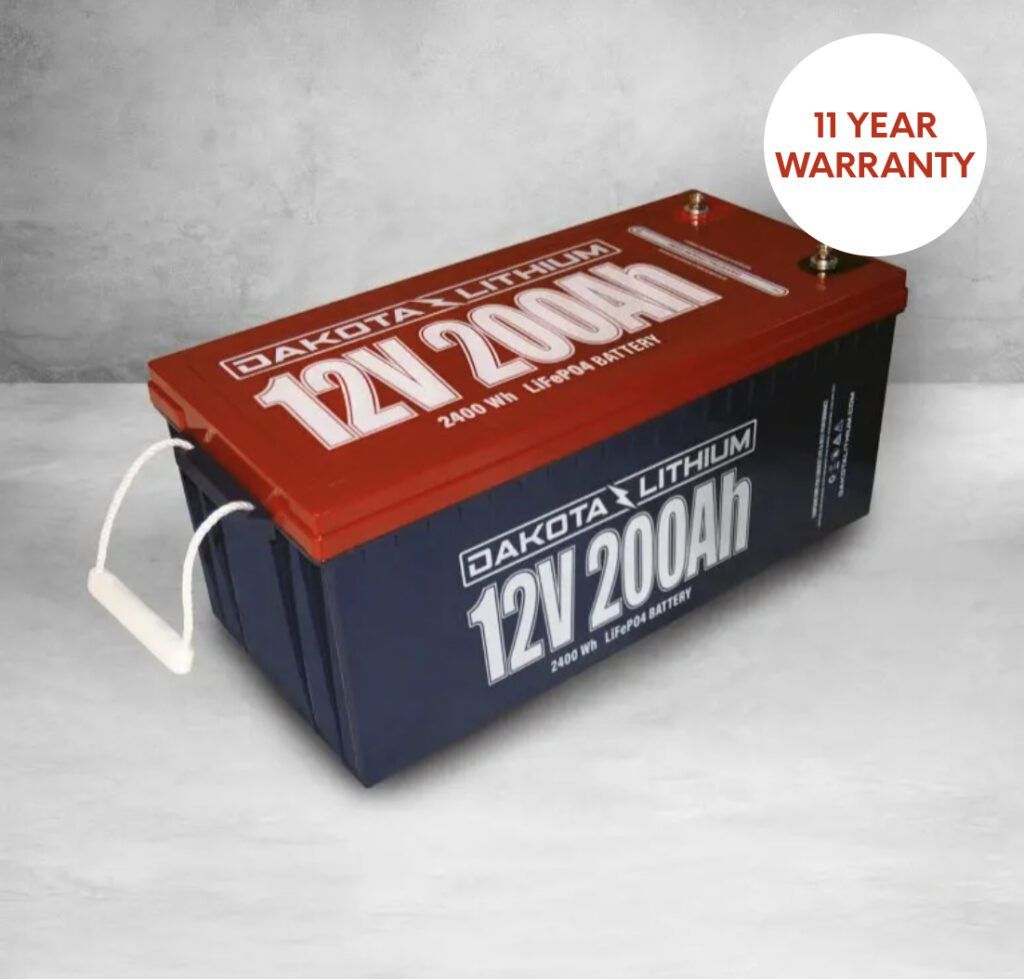

Additionally, many of these batteries have insanely long warranties—in some cases 11 years—a welcome benefit when considering the higher cost of lithium batteries. Furthermore, the most reputable manufacturers of marine-quality lithium batteries conform to strict engineering testing and design measures to ensure safety following such standards as ISO 9001, UL, and ABYC, among others. A possible downside is the initial cost of these batteries. For comparison, a common brand 55 amp-hour (Ah) AGM lead-acid battery was recently priced several hundred dollars less than a 54 Ah lithium iron phosphate battery (or LiFePo4, an acronym you’ll see a lot). However, the lithium battery had a smaller, lighter casing, whereas the AGM was a larger, and much heavier Group 34 size. If you consider the lifespan of both batteries, the lithium costs less over time, provided your electrical system doesn’t need further upgrading, which could come at a considerable cost. We’ll dig into this next.

YOU’RE NOT BUYING JUST A BATTERY

Since most reputable lithium-ion batteries on the market for marine applications are built with the LiFePo4 chemistry, the next consideration is the design of the electrical system into which the batteries will be incorporated. If you’re seriously considering lithium batteries, think of your entire electrical system rather than just the batteries you plan to install. Staying within the safe operating limits of lithium batteries is the name of the game, so to that end, a Battery Management System (BMS) is required equipment. The BMS is the device responsible for preventing thermal runaway by monitoring temperatures, charge currents, and variations in voltage within the battery and overall system.

Many better battery makers build a BMS right into their batteries, but they can also be added to the system externally. If an anomaly is detected, the BMS stops current from leaving or entering the battery, effectively disconnecting it from the system until normal conditions resume. Think of the BMS as a sort of gatekeeper that only allows the batteries to perform their duties when optimal conditions exist. Some of these can even connect to your phone to give you information about the health of your electrical system, be programmed with certain alarms, and generally serve as a greater safety buffer. Plus, if you’re the sort of captain who likes to know what’s going on with all aspects of your vessel, this is a way to monitor your electrical system that goes light years beyond a voltage meter.Ensure lithium batteries, chargers, and associated equipment are tested in accordance with an appropriate test standard (e.g., UL 2054) and, where applicable, certified by a Nationally Recognized Testing Laboratory (NRTL), and are rated for their intended uses.

- Follow manufacturer’s instructions for storage, use, charging, and maintenance.

- When replacing batteries and chargers for an electronic device, ensure they are specifically designed and approved for use with the device and they are purchased from the device’s manufacturer or a manufacturer authorized reseller.

- Remove lithium-powered devices and batteries from the charger once they are fully charged.

- Store lithium batteries and devices in dry, cool locations.

- Avoid damaging lithium batteries and devices. Inspect them for signs of damage, such as bulging/cracking, hissing, leaking, rising temperature, and smoking before use, especially if they are wearable. Immediately remove a device or battery from service and place it in an area away from flammable materials if any of these signs are present.

- If batteries are damaged, remove them from service, place in fire resistant container (e.g., metal drum) with sand or other extinguishing agent, and dispose in accordance with local, state, and federal regulations. Contact a local battery recycling center for disposal instructions.

- Follow manufacturer’s guidance on how to extinguish small battery fires, which could include using ABC dry chemical extinguishers, Class D fire extinguishers (for lithium-metal), dirt, or sand.

- Source: Occupational Safety and Health Administration. www.osha.gov

LITHIUM BATTERIES 101

With more boaters seeing the future in the form of batteries that can last longer, charge better, and generally be an overall more efficient power source, it’s time to discuss the basics of lithium-ion battery technology. Serious sailors need to know this stuff. Lithium-ion batteries last longer, are more energy-dense, and charge faster than their lead-acid peers. They have a low self-discharge rate and do not contain the heavy metals of other batteries. The advent of safe and reliable lithium-ion battery technology has made it possible for onboard power systems to be more efficient, more robust, and far safer than ever before. With proper planning and guidance, you can create a state-of-the-art power system on your boat that can meet all your electrical needs safely. Be aware that opinions on this topic vary from the academic to the conspiratorial. This subject is full of rumors and hearsay, generally transmitted by people armed with little research, so it’s worth knowing a little of the science, a bit of historical perspective, and most importantly, the professional best-practices associated with lithium-ion battery technology. The next time you hear rumors and innuendo at the dock, you’ll have the knowledge to set the record straight!

WHAT DOES ABYC SAY?

First, and most importantly, the American Boat and Yacht Council (ABYC) now has a set of standards that directly relate to the installation of these battery systems—ABYC E-13. This is a game-changer for several reasons. Among them, insurance companies now have a basis for approving coverage of boats with these systems (whereas before, coverage could have been denied), surveyors have a set of standards against which to inspect installation integrity, and manufacturers have the responsibility of providing product-specific recommendations for proper installation.

All of this is done in the name of safety, because installing these battery systems is not as simple as changing out a lead-acid battery for a lithium-ion battery, and most of the more negative impressions of these batteries are likely the result of improper installations that resulted in some level of calamity, which led to gossip and misinformation. You may recall evening news stories of cellular phones bursting into flames or aircraft making emergency landings due to fires started by lithium batteries in cargo holds. Recently, a cargo ship suffered a fire on the bridge that was traced back to the lithium-ion batteries in a handheld VHF radio left on its charging base. Fortunately, there were no injuries other than to the ship. Many of these fires likely started as a result of an overtemperature condition—uncontrolled heat—which is one of the four ingredients of fire, and early lithium batteries, particularly those in small handheld electronic devices were typically involved. Not all lithium-ion batteries are the same, and their chemistry and construction plays a critical role in their overall level of safety. The term “lithium-ion” is a categorical term rather than a specific chemistry. Early on, different materials such as manganese-oxide and cobalt-oxide were used to optimize electrical efficiency, cost, material availability, and safety. These components were very prone to “thermal runaway”, a condition that creates a fire that typical fire extinguishers cannot mitigate if the extreme heat cannot be controlled. With further research and testing, lithium-iron-phosphate (LiFePo4) chemistry emerged as the best and safest of lithium-ion applications for marine power. This chemistry was safer for several reasons. First, it has a higher thermal runaway threshold of 270°C (518°F). Second, batteries constructed with this chemistry included internal protective failsafe measures to protect from thermal runaway, which will be discussed later, and if all else failed and a fire did result, it could be extinguished with a Type B (flammable liquid) fire extinguisher.

SOME CAUTIONS ABOUT CHARGING THE SYSTEM

One area that needs particular attention if you plan to go the lithium route is your charging scheme. Though these batteries can be charged in all the traditional ways that other batteries can charge (solar, wind, shore, alternator), how they charge is a little different, and your system needs to be able to provide the right voltages and charge cycles to properly maintain the lithium bank(s). Because lithium batteries can take on voltage quickly (the bulk and absorption phases of the charge cycle), it is important that your charger delivers the proper charge current. Too high or too low, and damage or incomplete charging can result. Many chargers can be configured to charge lithium batteries, but you will need to match the charge current to the demands of your batteries. Manufacturers can help you assess whether your current charger is up to the task, or if other options might be better. Most reputable battery charger brands also have models that can handle lithium, and even have some that can handle a variety of battery types. Bottom line, know your system and its needs, and make sure the components will work together.

Many of us depend on the engine alternator as a primary means of replenishing power on longer runs away from the dock. Alternators can generate massive amounts of current that can be deposited right into your batteries. With lead-acid batteries connected to our alternators, we don’t worry too much about the amount of current going from alternator to battery; the higher resistance of lead-acid batteries prevents them from taking too much current in most installations. With lithium, however, this is a serious concern. Because lithium batteries have far less resistance, they can take a lot of incoming current and charge quite quickly. However, because the BMS manages the current coming into the battery, and because alternators throw gobs of power downstream as they spin, the BMS will likely stop the flow of alternator current when the battery nears peak charge. Now unregulated, the extra power coming from the alternator will cook alternator diodes and can surge back through the load bus of the electrical system, putting all your electrical devices (navigation instruments, for example) at serious risk, not to mention requiring you to procure a new alternator. This situation is prevented in several ways, typically through the installation of alternator regulators or DC-DC chargers. There have been many situations where boaters invested a lot of money into new lithium batteries without taking a system-wide approach and have ended up replacing components because of the aforementioned. They tell the person next to them at the bar, the story gets passed on, and soon we all have mixed feelings about lithium battery technology. Quite literally, knowledge is power!

Certainly, you can see why a system-wide approach is the best way to maximize the benefits of this battery technology and ensure that it operates safely. It is also of utmost importance that the batteries and equipment you select for your installation come from reputable manufacturers who conform to the safety standards outlined above. There are many lesser-expensive lithium battery products on the market that do not conform, use sub-standard circuitry and components, or both. Trying to save money here is a false economy. Instead, carefully plan your system and match the components to your needs. You will know if a manufacturer is reputable if they provide the service, support, and willingness to help you learn about how their products fit within your system, and if they establish specific recommendations for the installation of their products—this is a key element of the ABYC standard. Some manufacturers even offer online knowledge courses and video tutorials for free. Search their websites, speak to their technical advisors, and read their product information to gauge their quality and confidence in their products before buying.

Practical Sailor will be covering the lithium conversion quite a bit in coming months. Tell us your story with lithium—good or bad— in the comments area below.

RE: Lithiums…. I have had one for my house battery on my own boat for a good number of years. I am very happy with it’s performance.

As a marine electrician, I have installed a number of Lithium systems for my customers. I agree… It is definitely important to take a systems approach. Items I focus on are:

1) Alternator needs an external regulator that monitors the alternator temperature and throttles it back if it gets too hot. A single 100 Ahr Lithium can and does absorb 40-50 amps of charging when charging first starts.

2) Alternator output wire must be large enough…….. I find most boats are badly undersized.

3) Is there a voltage sensitive switch being used to share charge with other banks (e.g. Blue Seas ACR)? These will not work because Lithium resting voltage is too high. This will have to be replaced with a Lithium compatible product (eg Victron Cyrix Li Ct).

4) Most Lithiums are not designed to be start batteries. The BMS will shut down the battery with the high amps required for engine cranking.

5) The DC/DC transformers that I have seen tend to have very low amp outputs. Using these to charge Lithiums, in my mind, defeats the Lithium advantage of fast charging. I try to avoid them.

Dakota and others are beginning to offer batteries they claim are suitable for starting. I’ve got a cat w/ Yanmar 57hp engines, the starting batteries sure are a lot of weight in the rear of the boat. Would love to upgrade them to lithium – Practical Sailor – would be a great follow-up article on the things to watch out for when converting to Lithium starting batteries.

New subscriber here but already impressed with my subscription.

One thing I would like to point out in this very good article is the statement “Many better battery makers build a BMS right into their batteries, but they can also be added to the system externally.” is misleading.

It implies that a built-in (serial) BMS is, in some way, a better design than an external (parallel) BMS control circuitry. Notwithstanding that “better” and “best” are subjective and are largely dependent on the design of the system, there are several external BMS/battery designs such as Lithionics, Victron, MG, and others, including some DIY battery external BMS’s (REC) which offer safety capabilities well beyond the drop-in style LFP battery.

In addition to the basic BMS battery protective functions (cell and pack), they have communications (CAN) with an external alternator regulator which allow the BMS to manage the charge source safely, including a pre-signal to gracefully shutdown the high alternator current prior to an impending BMS disconnect (load dump). There are CAN communicating serial BMS’s but I have yet to see one be able to control the Wakespeed or Zeus through the CAN bus. This is a part of the E-13 recommendations (notes) which, disappointingly, did not get integrated into the standard as a minimum. (Standards are a consensus process and often get political with legacy product manufacturers lobbying hard for their installed base and less capable designs.)

I really liked the article’s theme of a systems approach. Too often consumers look only at a spec or price ($/Wh) as the overriding criteria and not the whole electrical system. It frequently ends with a diminished capability and frustration.

It truly is awesome to have air conditioning on the hook without a genset.

We have had a LFP house bank for a year. We have AGMs for start and bow thruster. Basically all charging charges house bank (alternators, inverter/charger, solar). Alternators have Balmar MC614 external regulators. The house bank charges start and thrusters batteries thru 3 30amp DV to DC chargers. Seems to work great. Very happy with upgrade!

I have 3 – 100Ah LFP batteries, and one 100 Ah AGM as a start battery, in a 37 foot sailboat. My 120 amp alternator is governed by a Balmar 614 regulator, and the connection between alternator and start motor is removed. Thus my system is: Alternator to positive buss of the LFP batteries; a lead from here to a DC to DC converter which leads to the AGM start battery; a ‘smart shunt connected to the negative buss of the LFP batteries; then to ground.

At this point (one year in) I have used the Balmar 614 ‘s belt load management to de -power my alternator to about 85 amps. All this is working well and all of the advantages of LFP batteries are evident, including much faster charging form my two 60 watt solar panels.

There is however an assumption in all of this which I’d love your comment on: The LFP batteries have a built in BMS. I’m assuming that should the BMS want to stop all current input, that the DC to DC converter would still feed current to the start battery, and thus not shut the system down?

Great column, and yes for me lithium is the future for boats, and the cost is pretty similar to top grad AGMs.

I recently went on a journey to replace the flooded lead acid house bank batteries on my Tartan 37 with lithium ion batteries. I am keeping the AGM Start battery. After many hours reading the horror stories and bad advice on how to combine these different chemistries, It turned out to be relatively simple. Most of the information on this subject comes out of the RV domaine. It assumes that the primary charging method is the alternator. A sailboat relies more heavily on solar and wind. Consider the direction of power flow. For an RV it is from the alternator to the AGM start battery to the lithium ion house bank. On a sailboat the direction is different. From the alternator, solar, wind and shore power to the house bank and then to the AGM start battery. In each case there is a dc-dc charger between the AGM battery and the lithium ion batteries. My conversion involved replacing the alternator voltage regulator, the magnum inverter charger, and reprogramming the solar controllers to the lithium ion battery charging parameters. I then added a DC-DC charger programmed to the AGM charging parameters. This essentially created a trickle charge from the lithium ion batteries to the AGM to keep it topped off and ready to start my engine.

Like many other articles I have read this one talked about Lithium being similar or even cheaper over the battery lifespan than lead acid. This may be true if compared to AGM or any other ‘sealed’ lead acid and possibly true compared to flooded 12v batteries. If comparing Lithium to quality 6v flooded lead acid it is probably not true. In a typical cruising boat with a house bank of 350Ah/hrs or above, 6v lead acid cells have a very similar cycle capacity to Lithium at a much lower cost and can be expected to have a lifespan of 10-15 years when properly managed. Most people do not realize how much difference there is between a true ‘deep cycle’ lead acid 6v battery and the lightweight 12v flooded or sealed one marketed for RV’s and small boats which at best can be expected to last 3-5yrs.

I’d be interested in information on how best to store Lithium batteries when the boat is hauled out for 3 to 9 months. I’ve read that 60% charged is better than 100%, but how do you maintain that level? Thanks

I am converting to Lithium. I have to say I think the denomination of LiFePo4 batteries should not belong in the family of Lithium-Ion LFP. For me they are distinctively different.

With LiFePO4 (LFP) in the long terms cells will get unbalanced , the BMS of the battery will protect the overcharged or under charged cell by shutting down the battery resulting in a blackout. Therefore it is important to have redundancy by putting 2 or more LFP batteries in parallel. Is this enough, not at all. To prevent cell inbalance you would have to open the casing of the batteries and check the level of each cell. Not convenient at all. This is why I recommend strongly going for batteries with bluetooth.

About the alternators:

I think one approach is as the author say using a DC to DC charger,but I think using an external regulator with a temperature sensor attached to the alternator will be more efficient.

There is also an other approach for the entire system and I believe this information can be found in the YouTube videos of Emily & Clark were he explain how to build an hybrid system with AGM or Lead and LFP batteries. He also explain how to modify your alternator to connect it to an external regulator and many other considerations like how to charge the LFPs properly. Fair winds.

Why can’t the DC to DC charger be used for the start battery rather than the house battery? Would the steady load of the charger be enough to protect the alternator if the LiPo batteries shut down under full charge? This would allow for full power of a large alternator on the LiPo batteries rather than a small 30amp DC to DC charger. What am I missing here? Maybe under a load dump the DC to DC charger on a fully charged lead acid start battery would not be enough protection. Any thoughts?

Good article. The advantages of LiFePO4 for large banks are compelling.

But I’m having trouble getting past the plain fact that ALL ICE cars use lead-acid for starting batteries. In fact, all EVs that I know of have a LA battery in there somewhere to handle minor electronics and controls (typically AGM or similar).

The reason, I think, is dumb robustness. It side steps the BMS that can interrupt and make the ship (or car) go dark. Imagine rolling down the street at 70 mph and everything going black. No power brakes (about 80% increase in effort). No power steering (about 70-75% increase in effort). No lights. And LA can charge below freezing but LiFEPO4 cannot, something they learned about in Chicago this past winter.

I wonder if lead is still not just a practical answer, but in fact the smart answer for sailors that:

* Day or weekend sail

* That have smaller banks, say less than 150 Ah. Pick a number.

I believe the dumb robustness of lead will keep it in mix for quite a while. My two new 2024 to 2025 ICE cars still use LA batteries. At $40,000 each, I don’t think money or complexity was the issue. They have cameras everywhere (they all but self-drive), auto everything, and loads of electronics. Lithium might even have been a selling point, but dumb robustness won. Lead still wins for my F-24 for dumb robustness, even though I would like the weight savings, because I like simple reliability better. Lead is also more recyclable.

But I have my ear to the ground.